Roller of heat-uniformizing hot-air de-enzyme machine

A technology of hot air degreening machine and hot air blower, which is applied in the direction of tea treatment before extraction, etc., which can solve the problems of large heat loss, low yield of finished product, and insufficient heating of tea leaves in the decapitation machine drum, and achieves low production cost, strong practicability, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

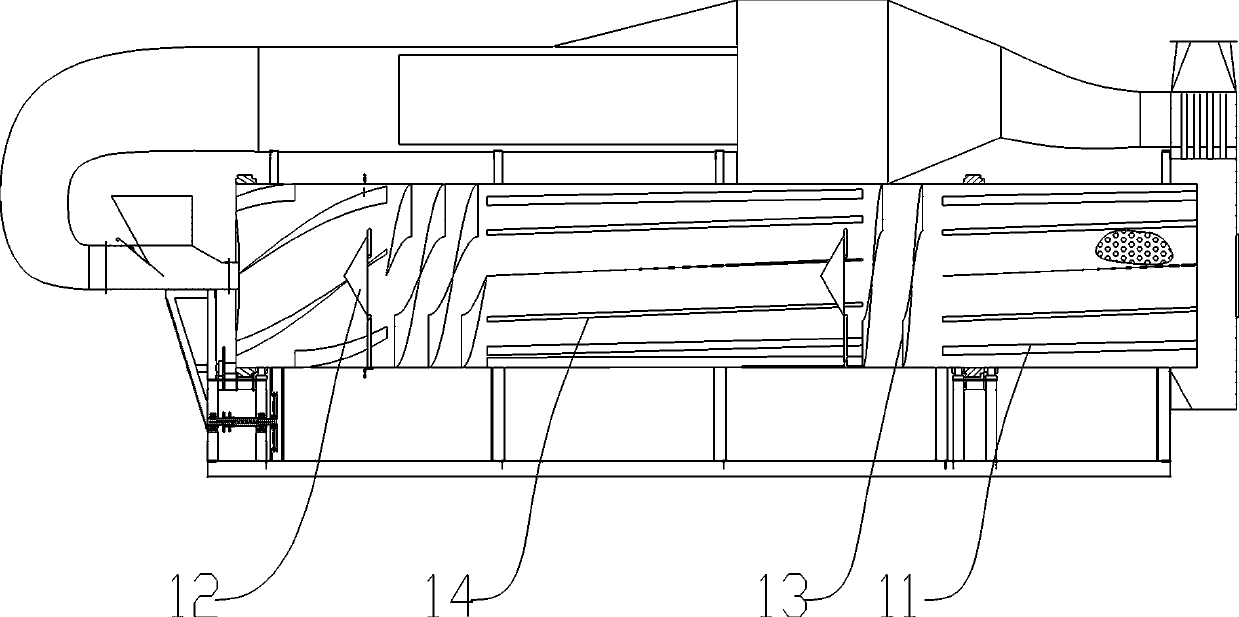

[0016] In order to further illustrate the technical means and effects of the present invention to achieve the above objectives, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. It should be understood that the specific embodiments described in the present invention are only used to explain the present invention, and are not intended to limit the present invention.

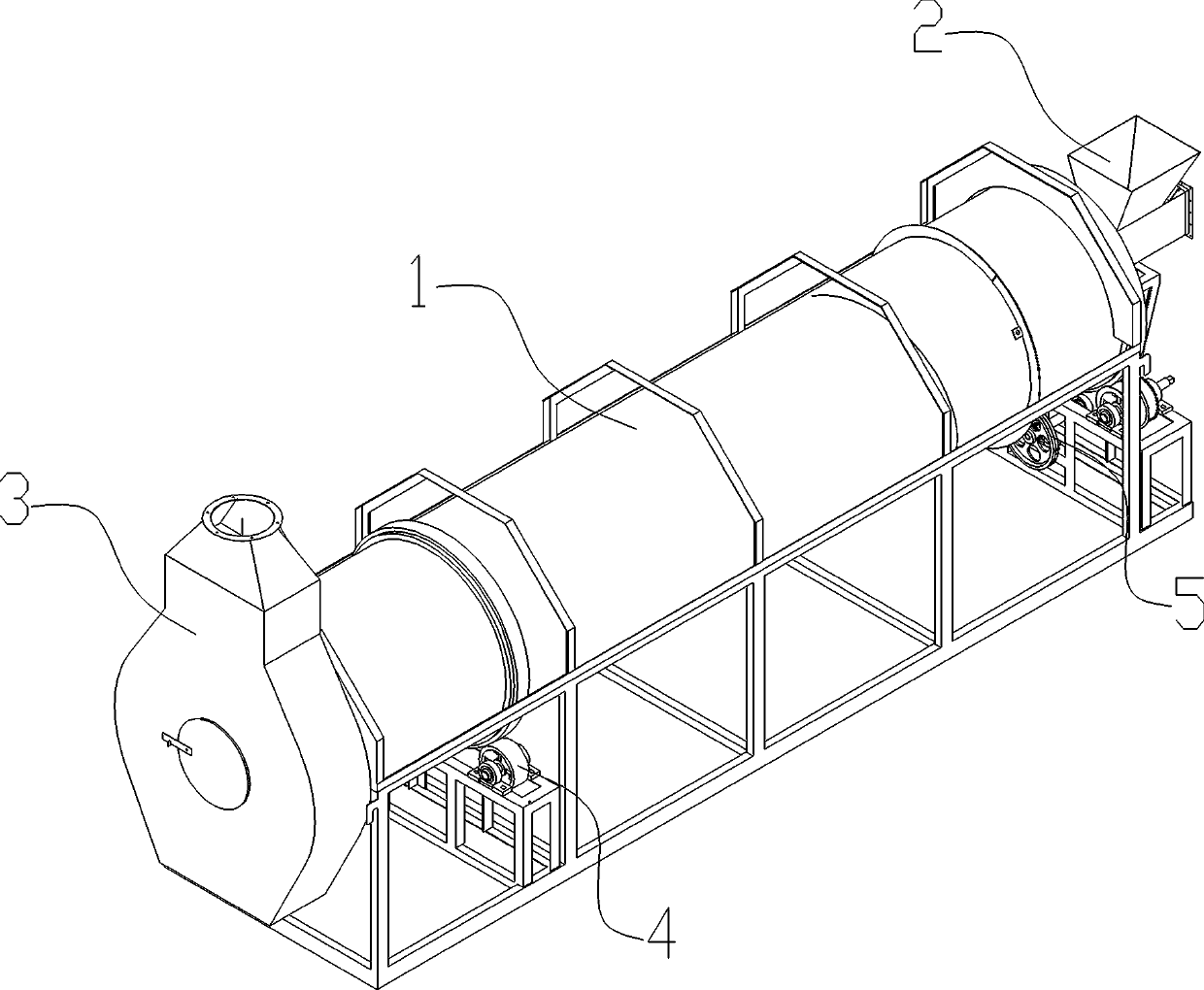

[0017] Such as figure 1 , as shown in 2, figure 1 It is a cross-sectional view of a preferred embodiment of the drum of the uniform hot air degreening machine provided by the present invention.

[0018] In this embodiment, the drum of the uniform hot air degreening machine includes a rotatable cylinder body 1, the hot air blower is connected to one end of the cylinder body 1 through the feed hopper 2, and the other end of the cylinder body 1 is connected to the exhaust duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com