Automobile lamp shell spraying and piece taking equipment

A technology for housings and lamps, applied in the direction of injection devices, etc., can solve the problems of not being practical and not suitable for manual entry operation, and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

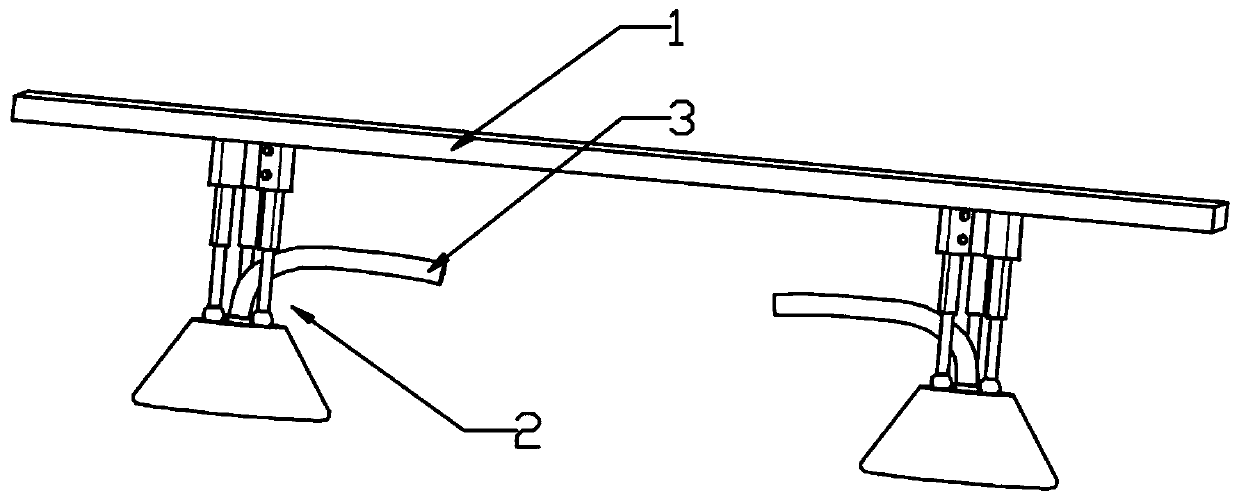

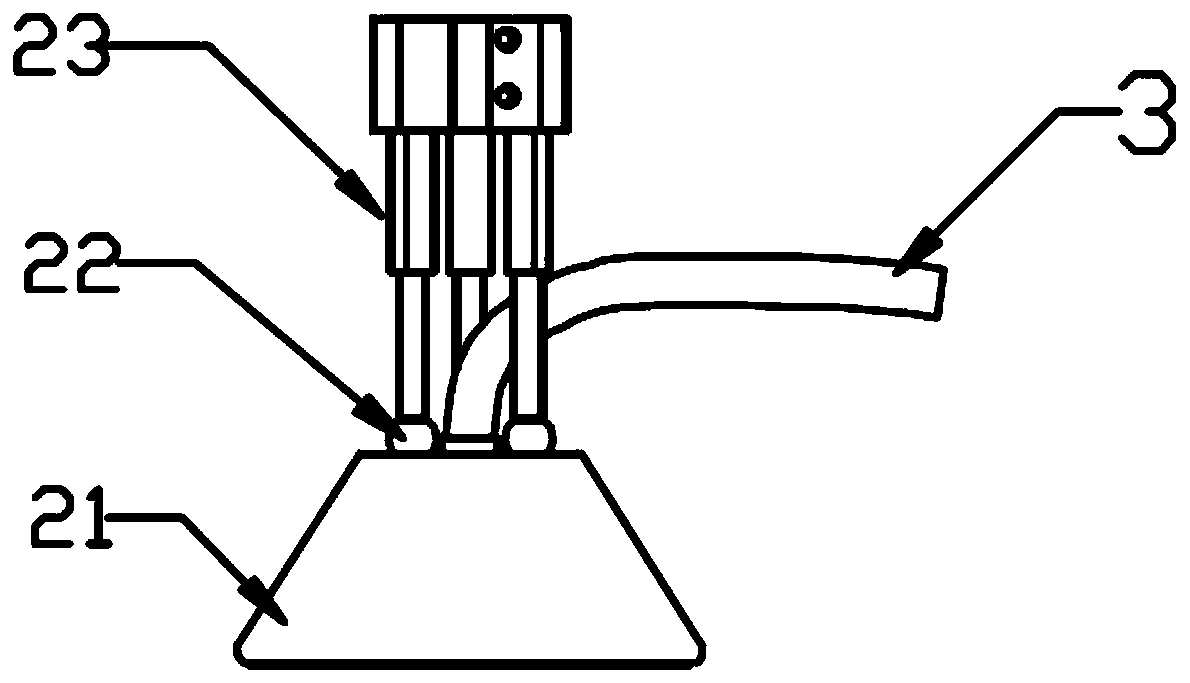

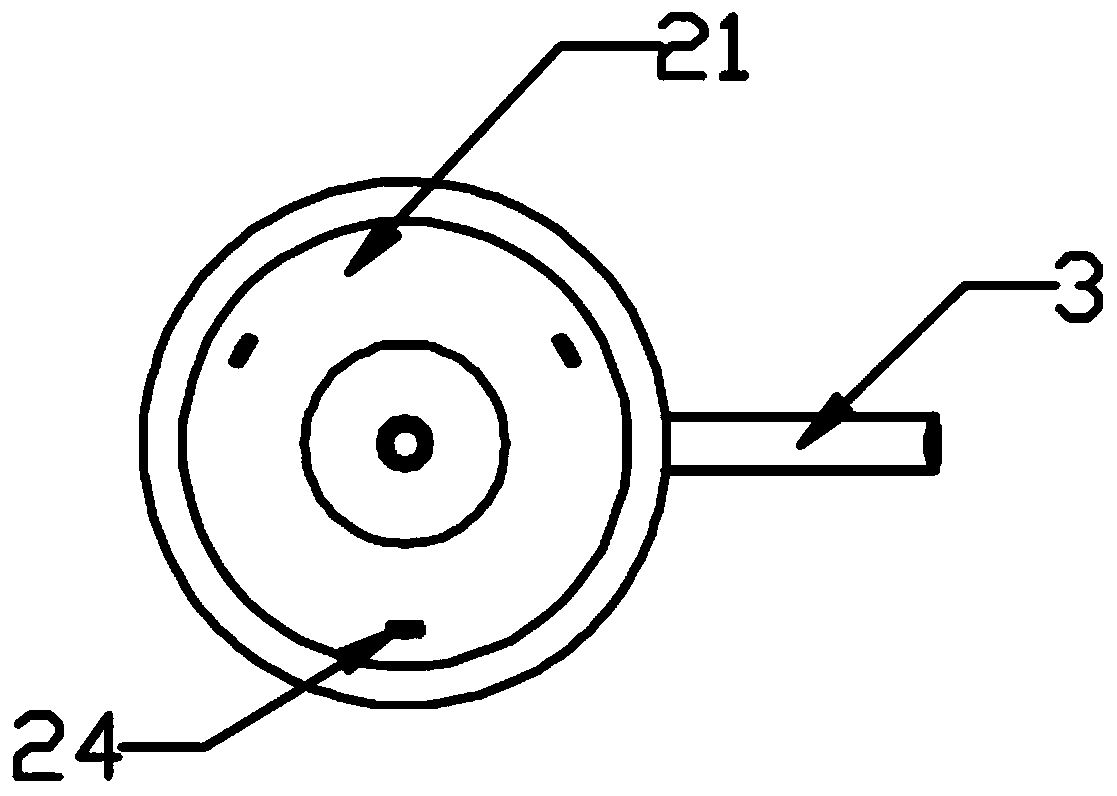

[0023] Such as Figure 1-3 As shown, a car lamp shell spraying pick-up equipment includes a support frame 1, and the bottom of the support frame 1 is connected with two grippers 2, and the grippers 2 include rubber suction cups 21, and the rubber suction cups 21 The internal cavity is conical.

[0024] The opening direction of the rubber sucker 21 is downward, and the top of the rubber sucker 21 is connected with the support frame 1 through three adjustment cylinders 23, the three adjustment cylinders 23 are distributed equidistantly around the circumference, and the push rod of the adjustment cylinder 23 passes through the spherical universal T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com