Automatic welding production line

An automatic welding and assembly line technology, applied in welding equipment, metal processing equipment, metal processing, etc., can solve the problems of low welding yield, low degree of automation, poor consistency, etc., and achieve the effect of easy understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

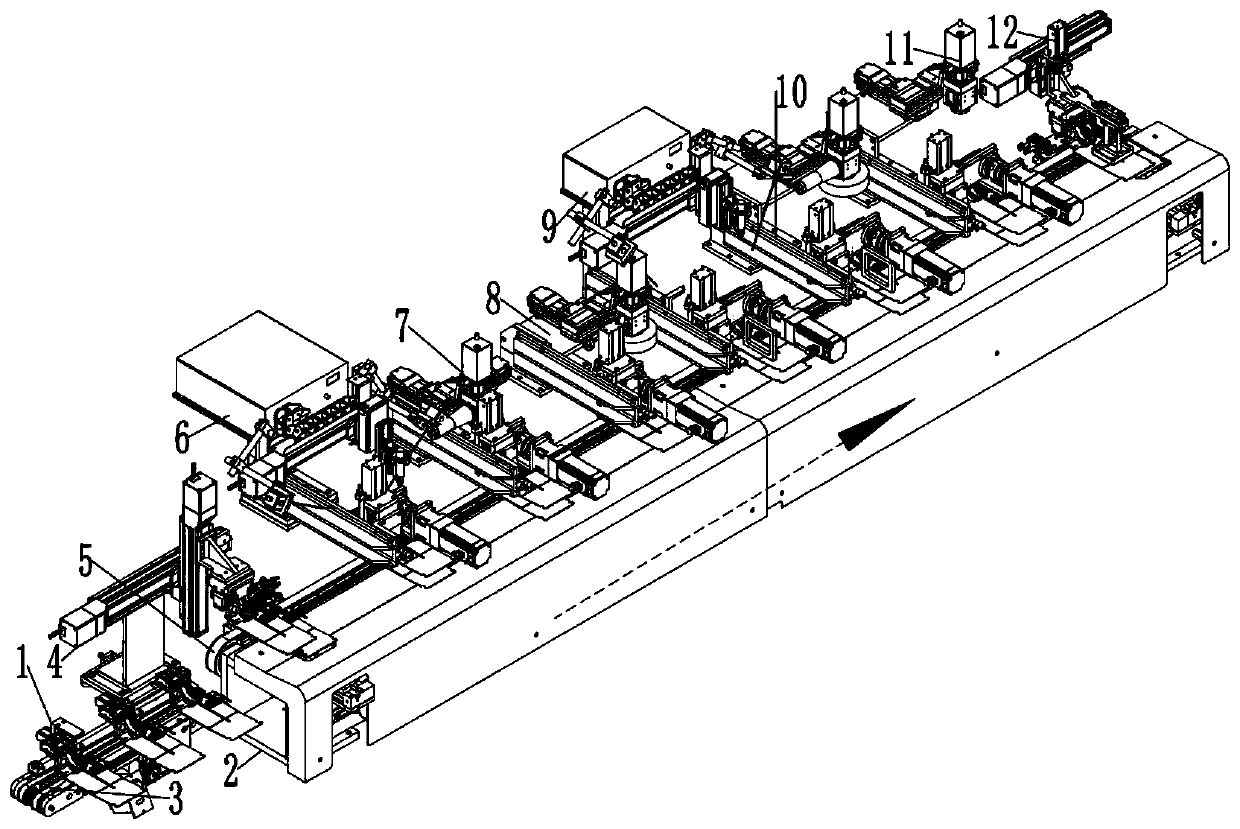

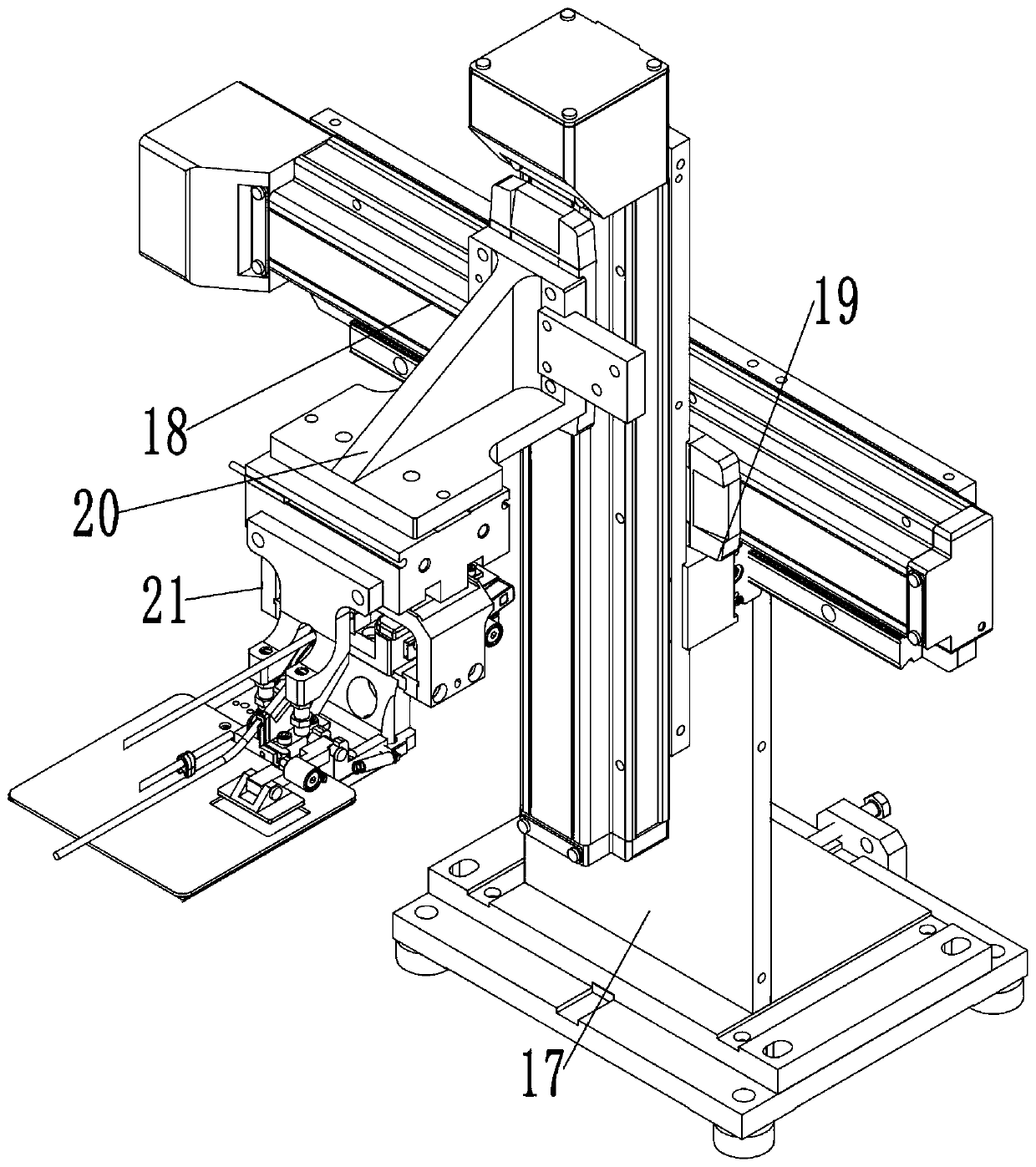

[0042] Such as Figure 1-8As shown, the automatic welding line of this embodiment includes a frame assembly 2, a feeding conveying device 3 arranged on the frame assembly 2, an input device 4 arranged at the output end of the feeding conveying device 3, and an input device 4, the main conveyor belt 5 on one side, and the tin spotting device 6, the precooling device 7, the photographing device 8, the soldering device 9, the cooling device 10, the trimming device 11, and the discharging device 12 which are sequentially arranged on the main conveyor belt 5;

[0043] At least three working manipulators for clamping electrical components 1 are arranged on one side of the main conveyor belt 5 .

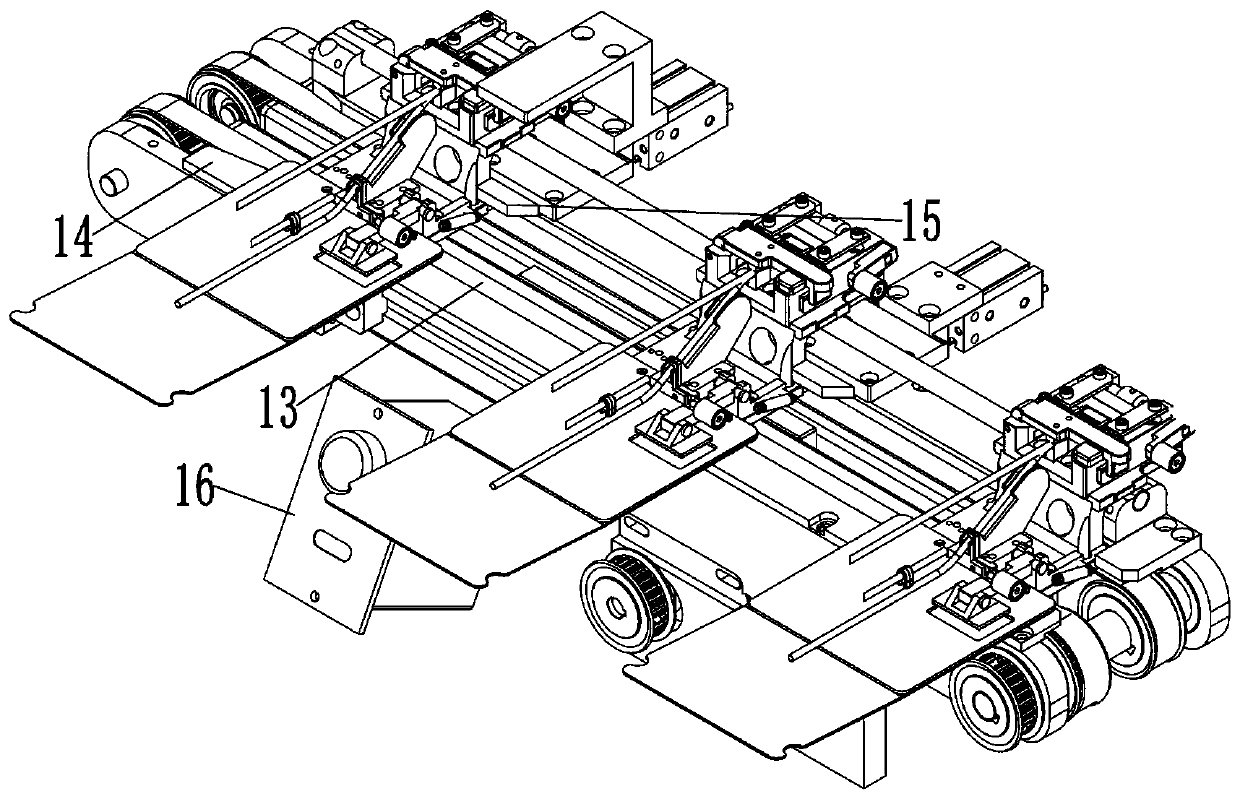

[0044] The feeding conveying device 3 includes a feeding conveyor belt 13 arranged vertically and used to transport the electrical components 1, symmetrically and vertically arranged on the feeding conveyor belt 13 on both sides of the feeding righting track 14, and horizontally arranged on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap