Laminated plate welding positioning device and positioning method thereof

A technology of positioning device and positioning frame, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems that manual welding cannot adapt to large-scale production, and it is difficult to ensure welding quality, so as to improve welding quality and production efficiency, positioning Precise, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

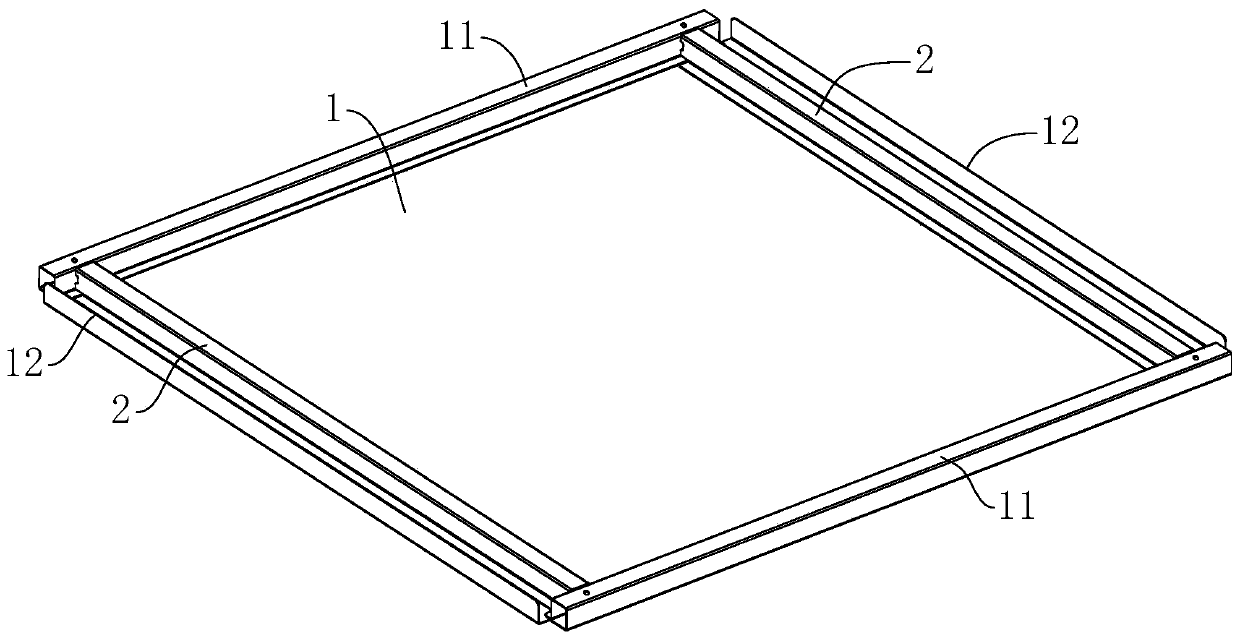

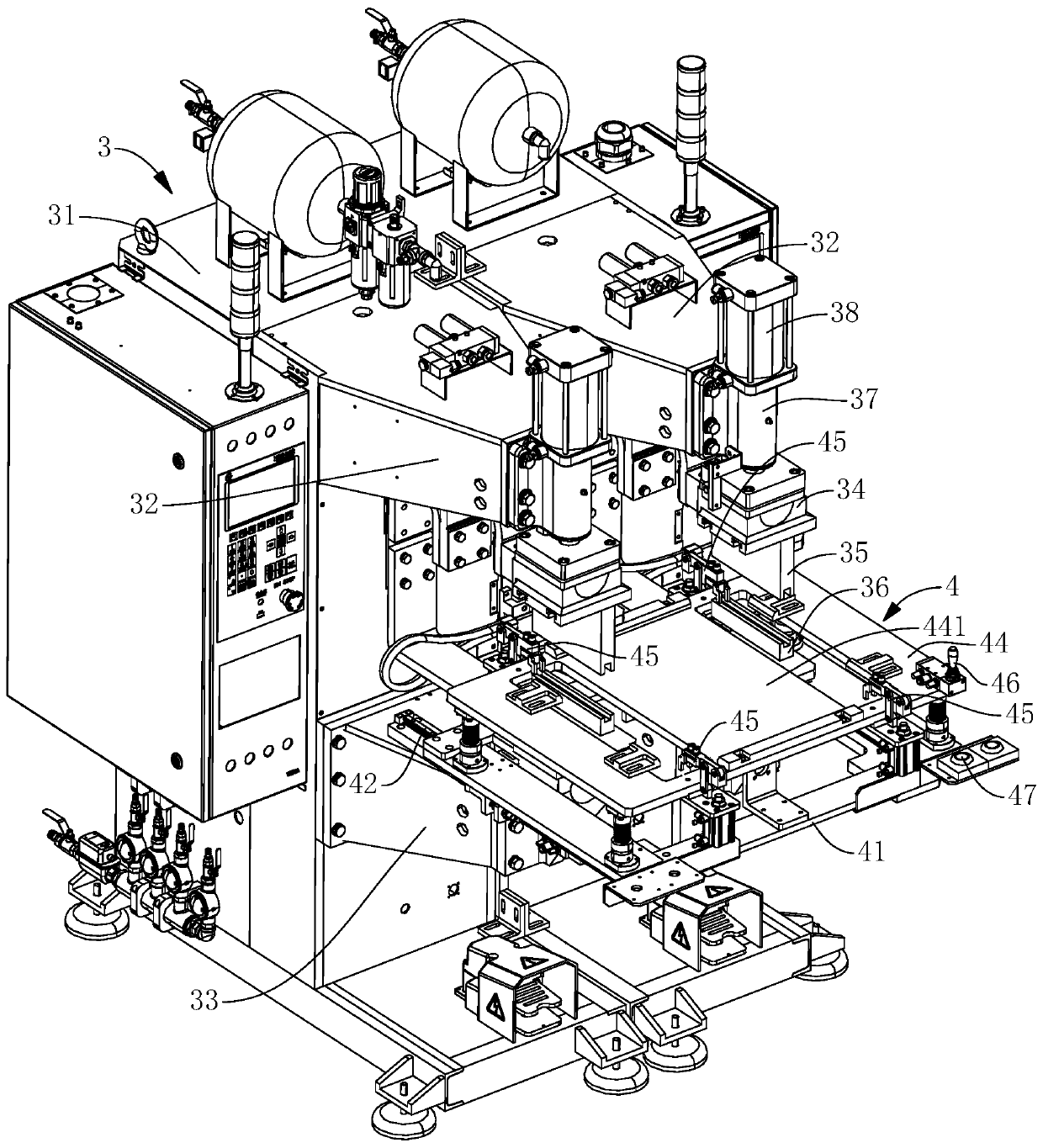

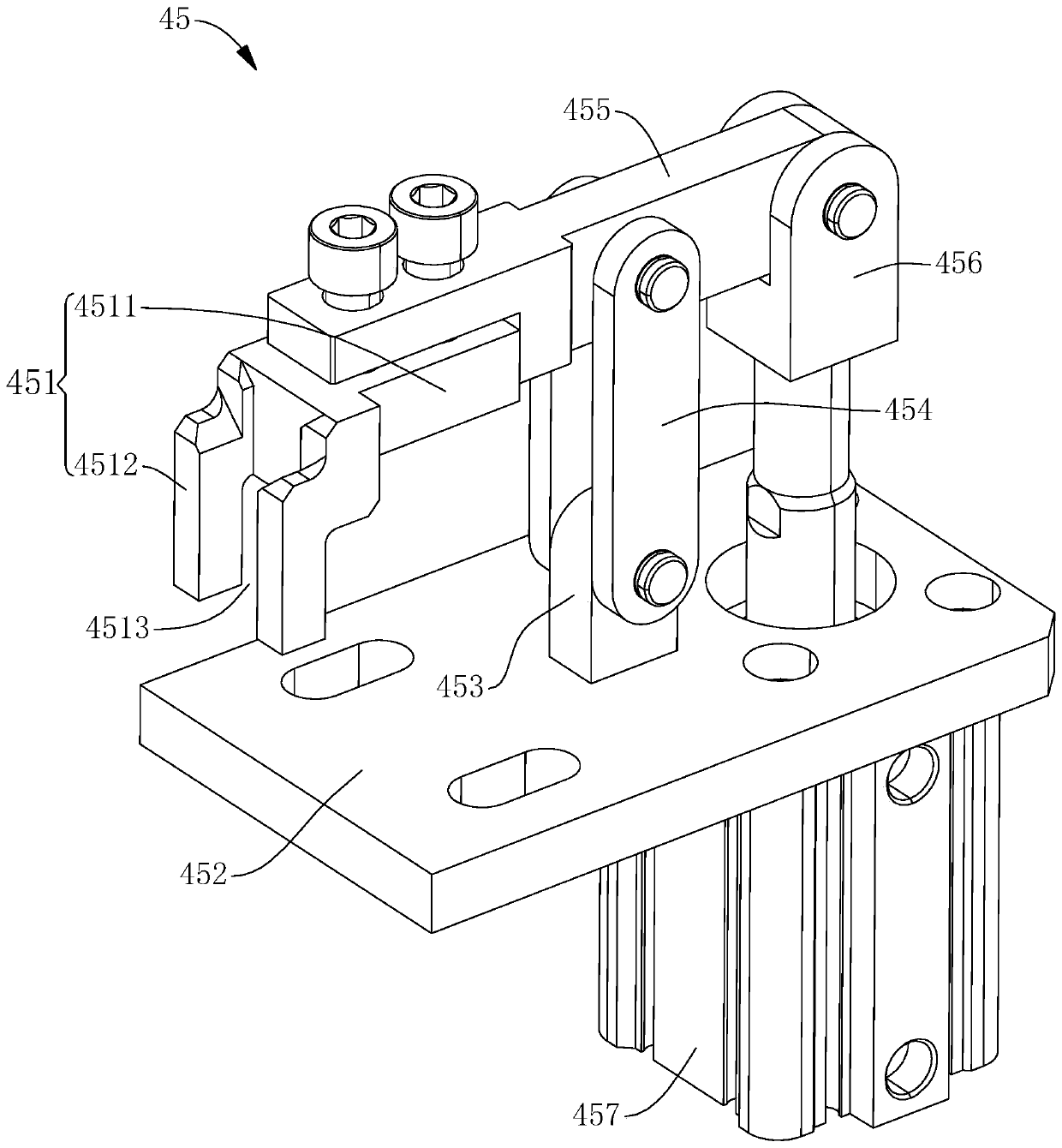

[0025] see figure 1 and figure 2 , the present invention provides a laminate welding machine, which is used to weld two clamping strips 2 on the main panel 1 to form a laminate. The laminate welding machine includes two welding machines 3 and positioning seats 4 arranged side by side. The welding machine 3 includes welding box main body 31, upper supporting arm 32, lower supporting arm 33, upper welding head 34, upper welding electrode 35 and lower welding electrode 36, upper supporting arm 32 is fixedly connected to the top of the front side of welding box main body 31, lower supporting ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com