Motor rear cover taking-out device of EPB motor gear unit

A technology of motor back cover and motor gear, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of not being able to meet production needs, affecting economic benefits, and low assembly efficiency, achieving assembly automation and reducing labor Strength, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

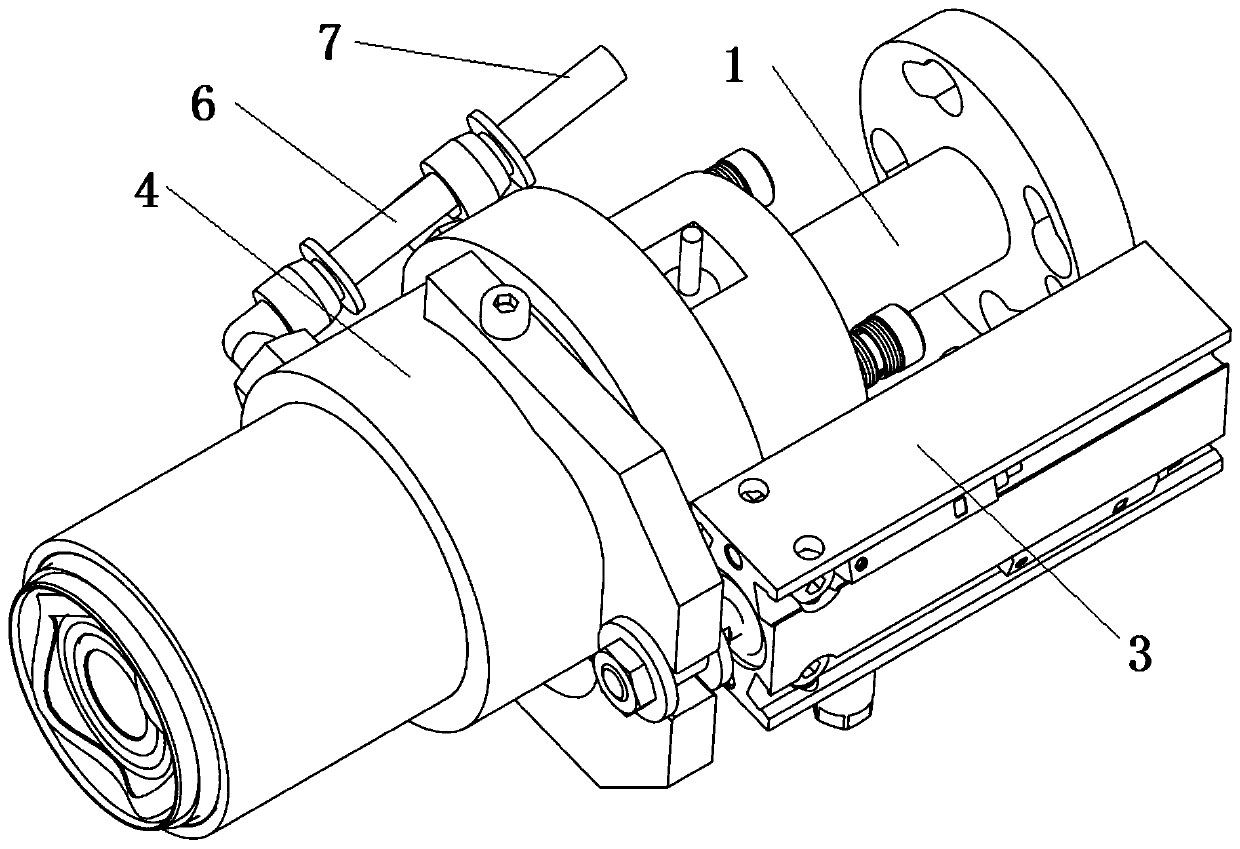

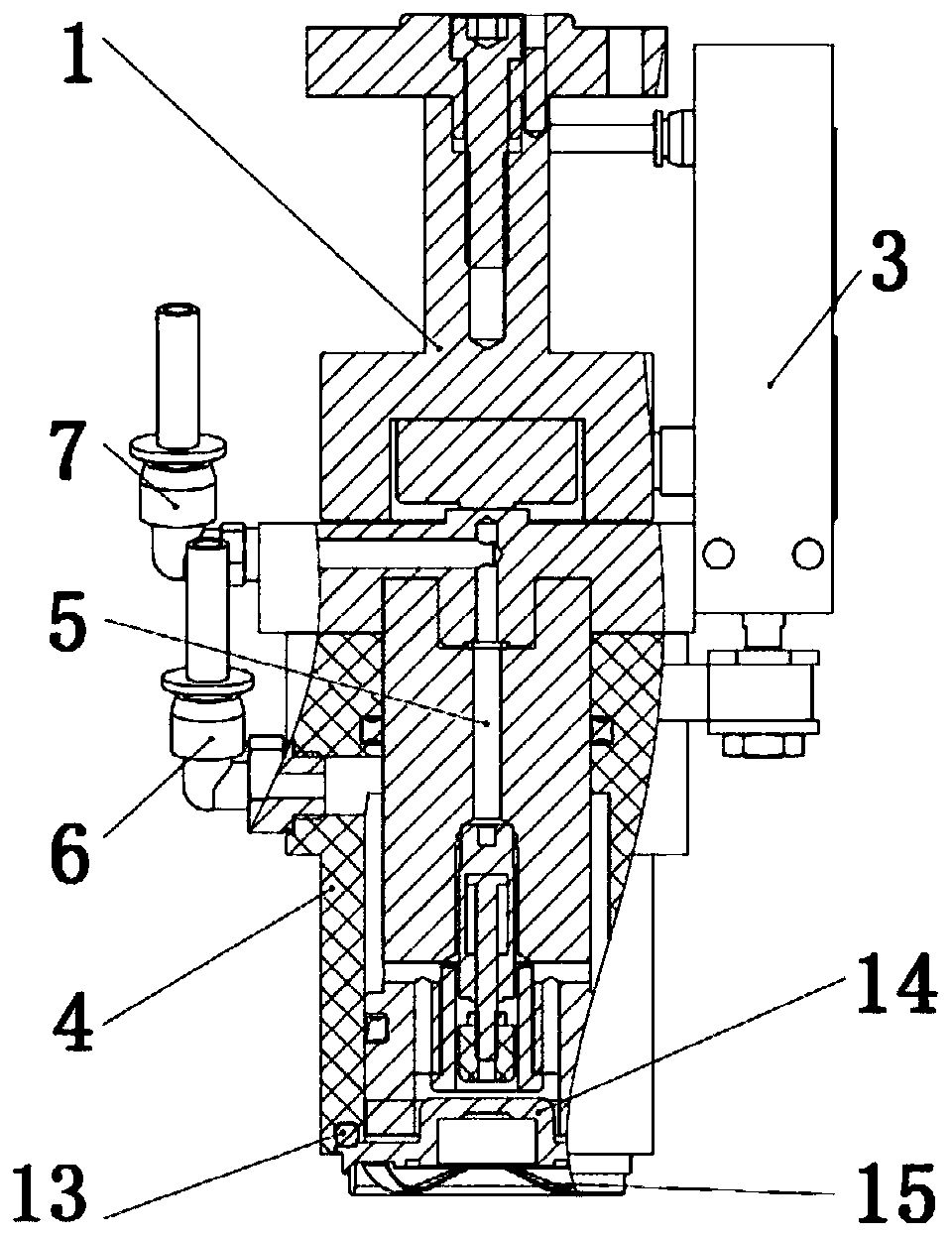

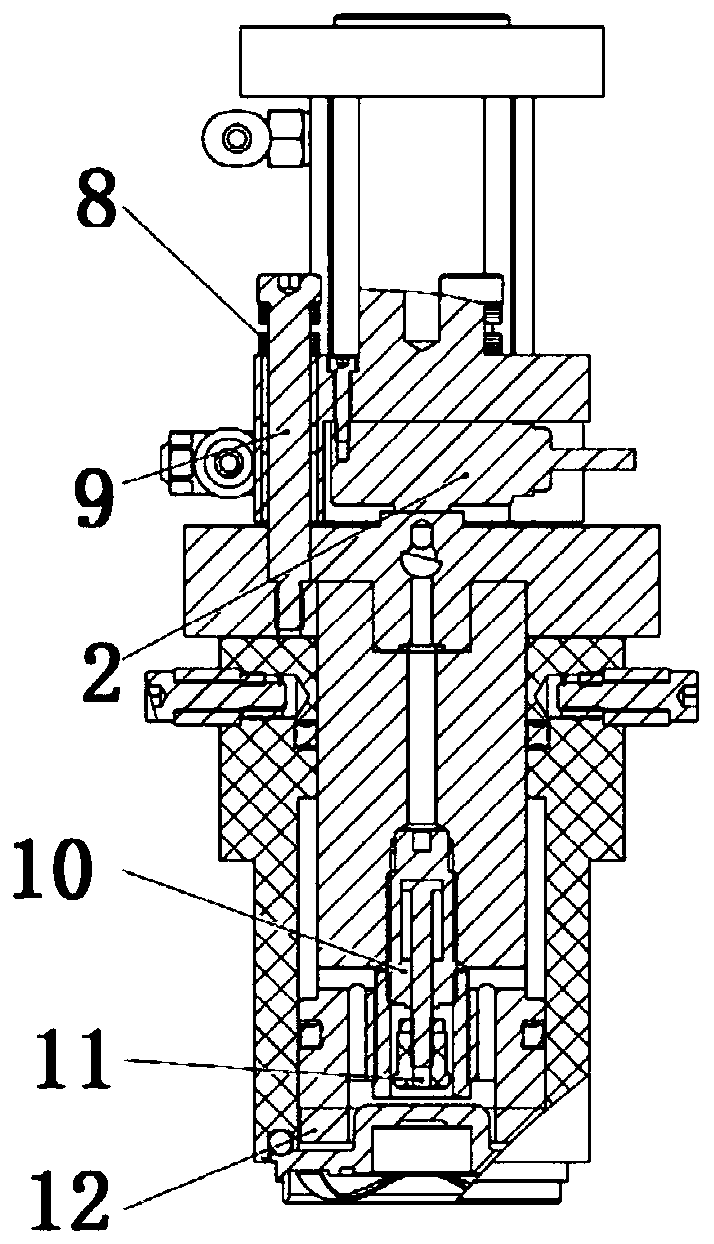

[0027] A kind of EPB motor gear unit motor rear cover pick-up device, such as figure 1 and figure 2 As shown, it includes the installation part 1, the feeding sliding sleeve 4, the feeding lifting mechanism, the magnet, the parts pushing out assembly 5, the force sensor 2 and the guide positioning rod 9; wherein, the feeding lifting mechanism is a double-acting cylinder 3, and the magnet is a ring magnet12. The parts ejection assembly 5 specifically includes a parts ejection assembly body, a thumb cylinder 10 , a pusher and a cylinder sleeve which are set in the take-up sliding sleeve 4 , wherein the pusher is a nylon pusher 11 .

[0028] The double-acting cylinder 3 is fixedly installed on the mounting part 1, and drives the retrieving sliding sleeve 4 to move along its axial direction; the lower part of the part ejection assembly body in the part ejection assembly 5 is installed in the retrieving sliding sleeve 4, and the cylinder sleeve Connect with the parts ejection as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com