A Method for Determining the Special Grinding and Grinding Amount of the Rough Broach Used in Steam Turbine Groove Broaching

A determination method, steam turbine technology, applied in the direction of broaching, grinding machine parts, broaching, etc., can solve the problems of unusable broaching, reducing the efficiency of rough broaching, increasing the cost of rough broaching, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

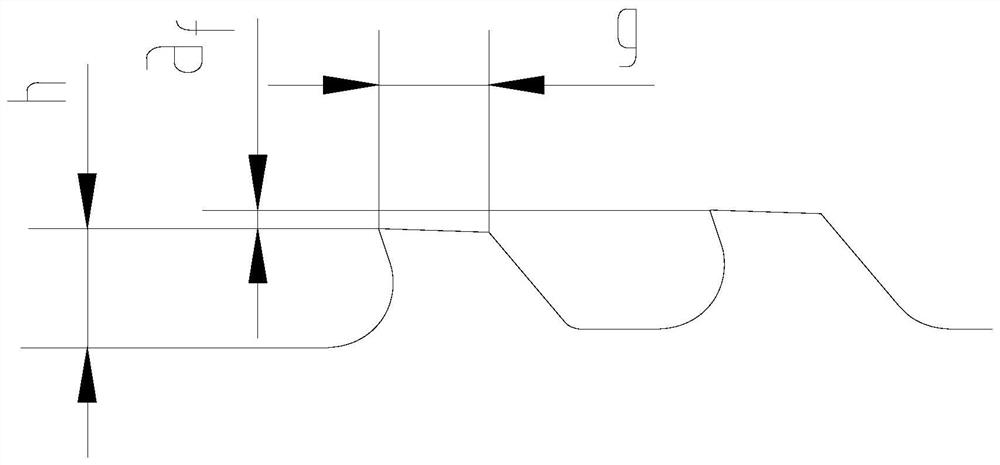

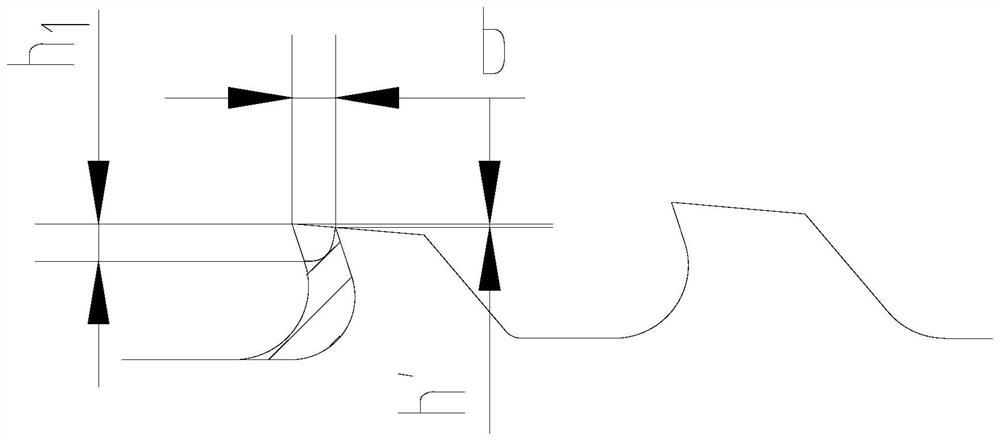

[0043] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a kind of steam turbine wheel groove broaching method for determining the special grinding and grinding amount of a rough broach in this embodiment, the method is realized by the following steps,

[0044] Step 1. Flaw detection inspection of damaged broach:

[0045] Before regrinding the damaged broach, the broach should be inspected for flaw detection. After the flaw detection inspection, the broach with cracks will be scrapped; the broach without cracks will be used as a spare;

[0046] Step 2. Inspection before grinding:

[0047] Refer to the broach broach allowance A of the broach without cracks according to the drawings, and check the tooth lift of the broach a f ;Put the damaged broach on the marble platform, and use the height gauge to measure the damage height h of the damaged tooth 1 and width b, to provide a basis for calculation;

[0048] Step 3. Calculate the num...

specific Embodiment approach 2

[0075] Specific implementation mode two: combination figure 1 and figure 2 The present embodiment will be described. The flaw detection method of the flaw detection inspection of the damaged broach described in Step 1 of the present embodiment is magnetic particle flaw detection or coloring flaw detection. Other compositions and connections are the same as in the first embodiment.

[0076] The basic principle of magnetic particle flaw detection: when the workpiece is magnetized, if there is a defect on the surface of the broach, magnetic flux leakage will occur due to the increase of the magnetic resistance at the defect, forming a local magnetic field, and the magnetic powder will display the shape and position of the defect here, thereby judging the presence of defects.

[0077] The basic principle of coloring flaw detection: the surface of the broach is coated with colorant, and the colorant penetrates into the damaged part. Rinse off the colorant on the surface after s...

Embodiment 1

[0079] Use the magnetic particle flaw detection method to inspect the damaged broach to ensure that the broach has no cracks before distributing the amount of tooth lift according to the following method, and then regrinding or reforming.

[0080] After the damaged broach has no cracks after the flaw detection inspection, check the tooth lift of the broach according to the drawing a f ;Put the damaged broach on the marble platform, and use the height gauge to measure the damage height h of the damaged tooth 1 and width b, to provide a basis for calculation;

[0081] When the number of damaged teeth of the damaged broaches n 1 =1, determine the number n of teeth to be ground and the amount of ground to be a 1 :

[0082] Determine the number of grinding teeth n:

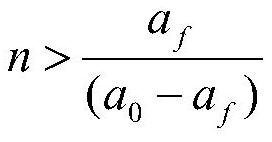

[0083] when h 1 >a f or , the damaged broach teeth are scrapped, and the number of teeth to be repaired is:

[0084]

[0085] when h 1 f or When , by allocating the gear lift, the number of teeth to be g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com