Primary curing oven for lenses

A technology for curing ovens and lenses, applied to other household appliances, household appliances, optical components, etc., can solve the problems of uncirculated temperature, long baking time, uneven oven temperature, etc. Same dry time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

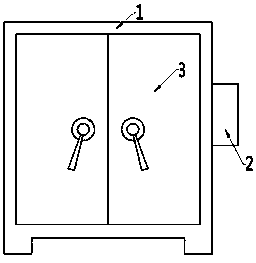

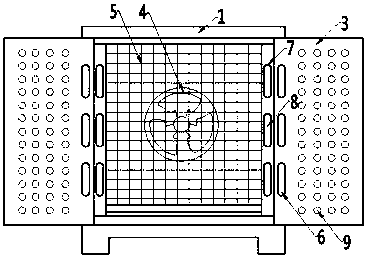

[0012] Depend on figure 1 , figure 2 It is known that a lens primary curing furnace is composed of a box body 1 and an electrical control cabinet 2. An electrical control cabinet 2 is installed on one side of the box body 1, and the operation of the box body 1 is controlled by the electrical control cabinet 2; the box body 1 The outer layer of body 1 is made of metal sheet, lined with thermal insulation mineral wool to prevent heat loss, built-in heating wire mesh, the temperature is adjusted by the operator on the electrical control cabinet 2; the box body 1 is sealed and connected with a box The door 3, the left side elevation, the right side elevation, and the inner wall of the rear side elevation of the box body 1 are provided with a circulating air duct connected with each other, and a circulating fan 4 connected with the circulating air duct is provided in the middle of the rear side elevation, and A heating wire mesh 5 is provided in front of the rear elevation; air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com