Sliding block ramp-roof core pulling mechanism and injection mold

A core-pulling mechanism and slider technology, applied in the field of molds, can solve the problems of difficult processing, long molding cycle, high equipment cost and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

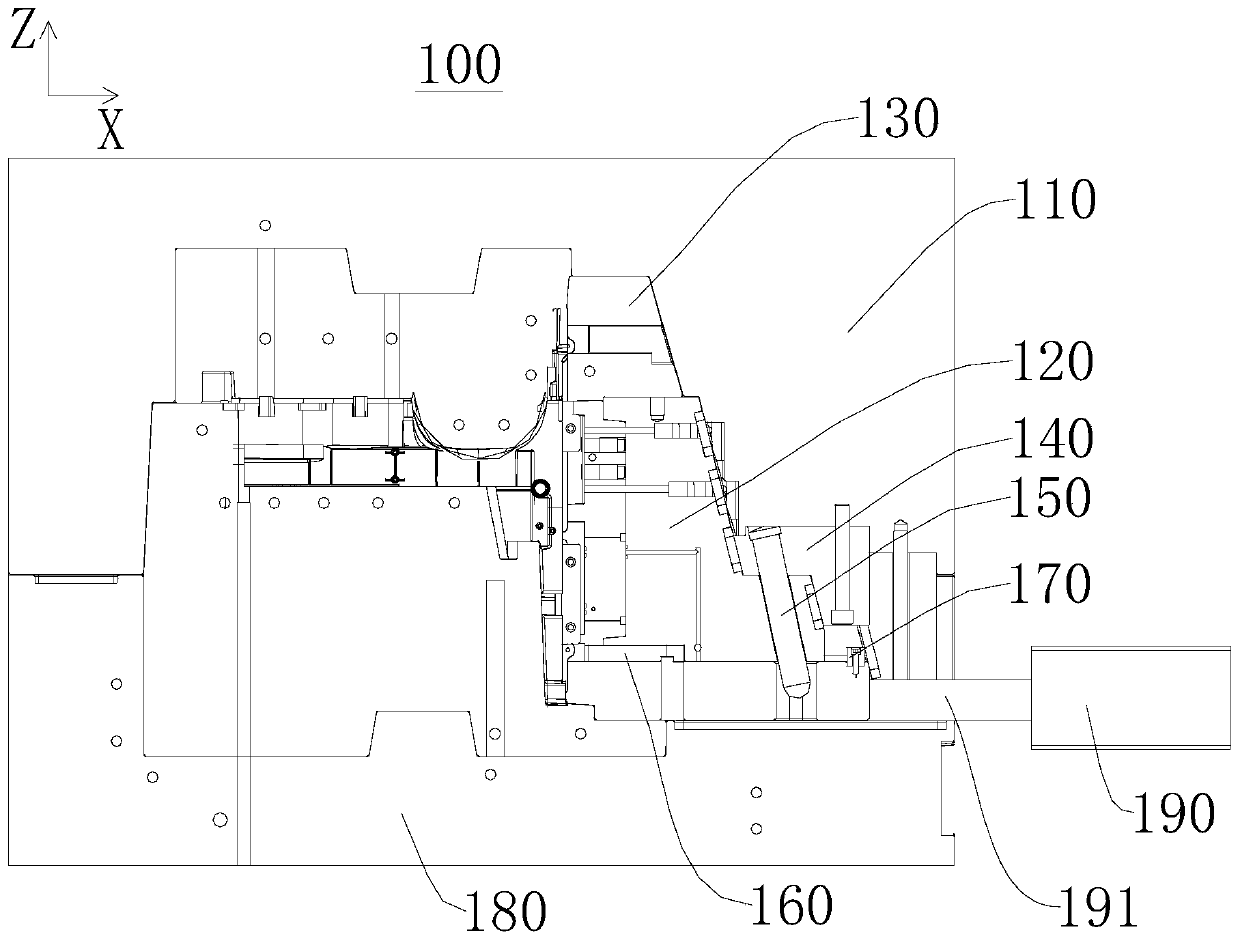

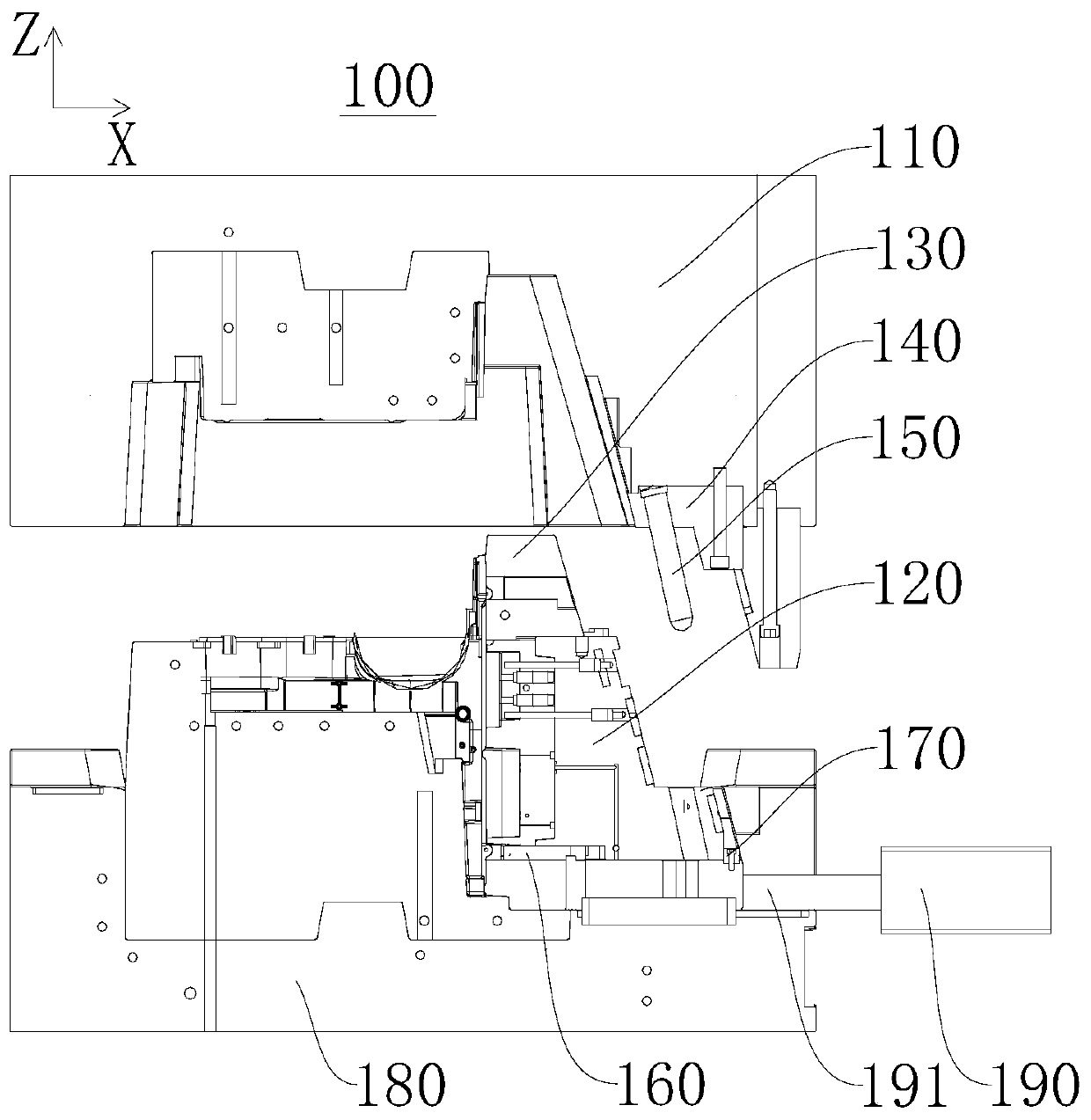

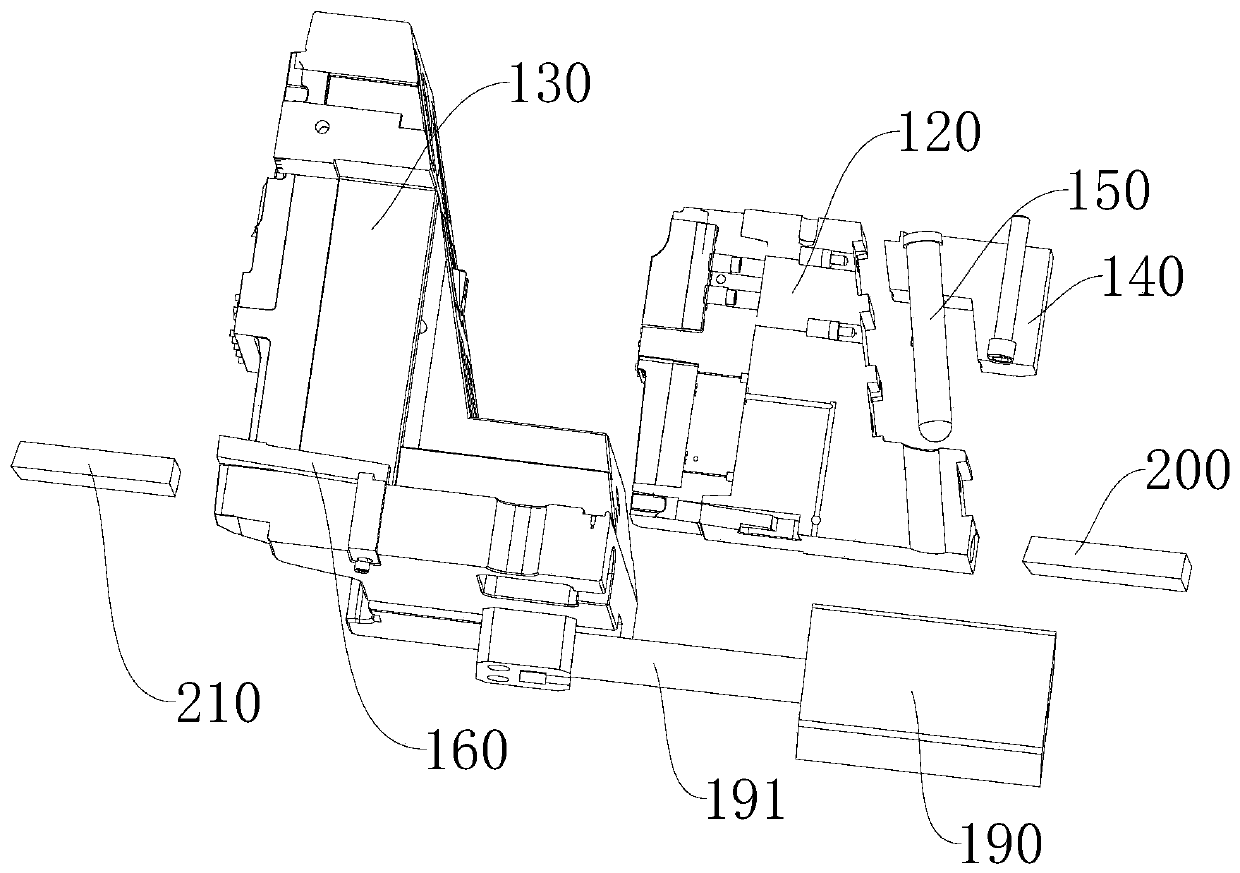

[0028] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , the embodiment of the present invention provides a slider inclined top core-pulling mechanism 100, which is used for core-pulling molding of products. It can complete the core-pulling work in multiple directions at one time, shorten the molding cycle, reduce equipment costs and labor costs, and the movement process is stable and reliable, and the product quality is high. In this embodiment, the sliding block inclined top core-pulling mechanism 100 is used for core-pulling the ribs on the product and the side holes opened on the side of the ribs. The direction is vertical, and the slider inclined top core-pulling mechanism 100 can simultaneously perform core-pulling molding in these two directions.

[0029] The slider inclined top core-pulling mechanism 100 includes a fixed template 110, a first slider 120, a second slider 130, a shovel base 140, an inclined guide column 150, an inclined top core-pulling...

no. 2 example

[0040] Please refer to Figure 9 , the present invention provides an injection mold 10 for producing plastic products. The injection mold 10 includes a slider inclined top core-pulling mechanism 100 , a fixed mold seat plate 300 and a movable mold seat plate 400 . Among them, the basic structure, principle and technical effect of the slider inclined top core-pulling mechanism 100 are the same as those of the first embodiment. For a brief description, the part not mentioned in this embodiment can refer to the corresponding content in the first embodiment. .

[0041] In this embodiment, the fixed mold base plate 300 is connected to the side of the fixed platen 110 away from the movable platen 180, the movable mold base plate 400 is connected to the side of the movable platen 180 away from the fixed platen 110, and the fixed mold base plate 300 is fixedly connected to the pressure On one side of the machine, the movable die seat plate 400 is fixedly connected to the other side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com