Plastic extruder low-load protection system

A protection system and extruder technology, which is applied in the field of extruder low-load protection system, can solve the problems of increasing the use cost of extruders, large extruders, time-consuming and labor-intensive problems, etc., to prolong the service life and increase the firmness , the effect of preventing sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

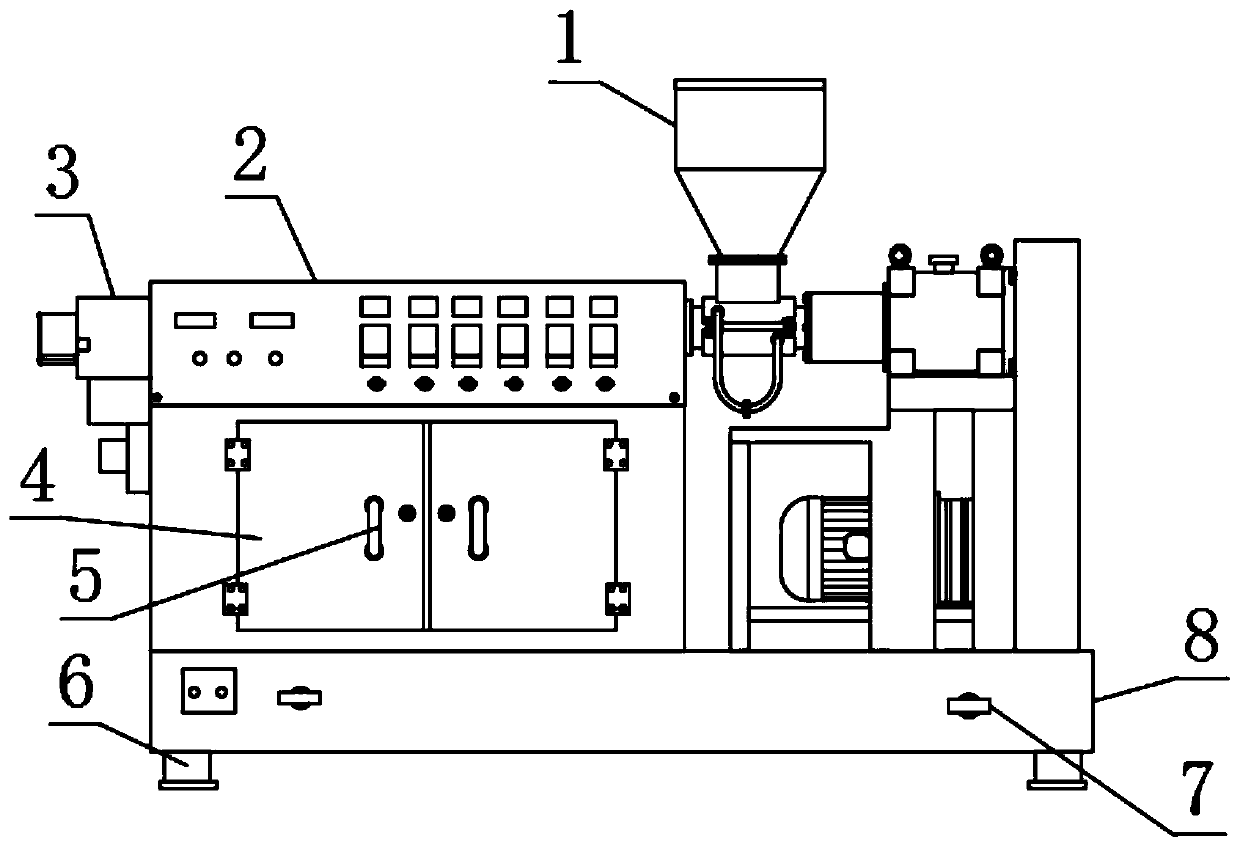

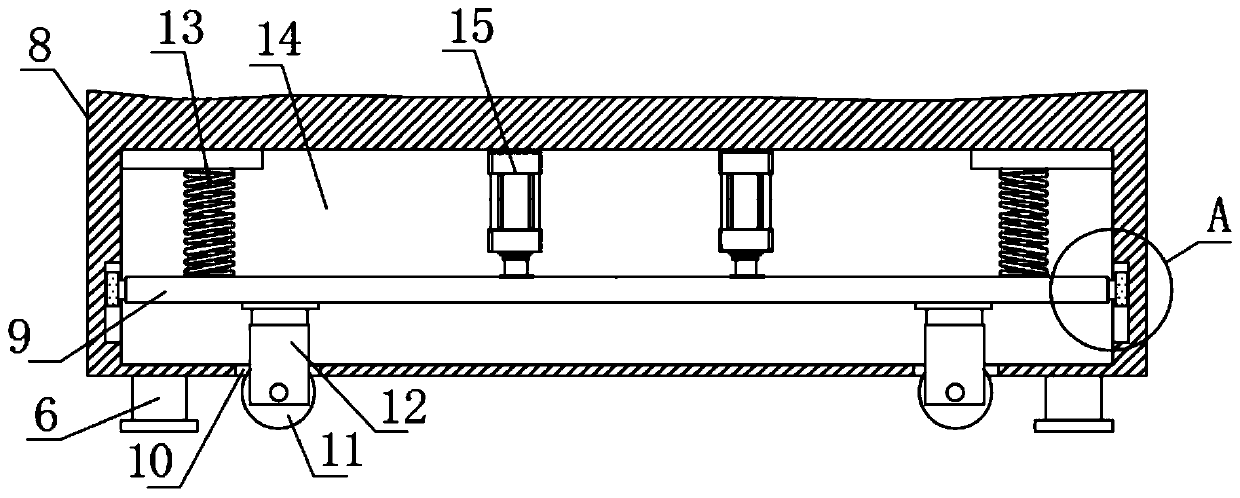

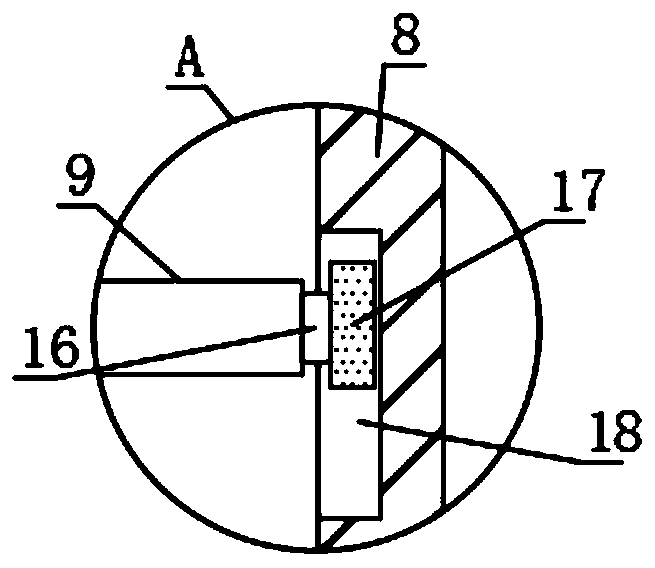

[0022] see figure 1 and figure 2 , the present invention provides a technical solution: extruder low-load protection system, including feed hopper 1, extruder main body 2, rotary extrusion screw 3, base 8 and a support mechanism provided on the surface of base 8, the inside of base 8 A moving mechanism is provided, and the moving mechanism includes a movable plate 9, a sliding hole 10, casters 11, a support column 12, a buffer spring 13, a fixing groove 14 and a cylinder 15, and the feeding hopper 1 is installed and fixed on the upper side of the extruder main body 2, The rotary extrusion screw 3 is installed and fixed inside the extruder main body 2, the base 8 is installed and fixed at the bottom of the extruder main body 2, the fixed groove 14 is opened inside the base 8, and the movable plate 9 is installed and placed in the fixed groove 14. Inside, the buffer spring 13 is symmetrically installed and fixed on the upper surface of the movable plate 9, and the cylinder 15 ...

Embodiment 2

[0030] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution: extruder low-load protection system, including feed hopper 1, extruder main body 2, rotary extrusion screw 3, base 8 and a support mechanism provided on the surface of base 8, the inside of base 8 A moving mechanism is provided, and the moving mechanism includes a movable plate 9, a sliding hole 10, casters 11, a support column 12, a buffer spring 13, a fixing groove 14 and a cylinder 15, and the feeding hopper 1 is installed and fixed on the upper side of the extruder main body 2, The rotary extrusion screw 3 is installed and fixed inside the extruder main body 2, the base 8 is installed and fixed at the bottom of the extruder main body 2, the fixed groove 14 is opened inside the base 8, and the movable plate 9 is installed and placed in the fixed groove 14. Inside, the buffer spring 13 is symmetrically installed and fixed on the upper surface of the movable plate 9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com