Integrated fertilizer production system

A production system and fertilizer technology, which is applied in the field of automatic fertilizer production equipment, can solve the problems that the column and the bottom plate are not easy to move, and the roller flattening effect is not ideal, so as to achieve the effect of high production efficiency and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

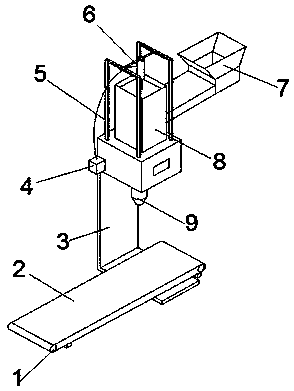

[0042] An integrated fertilizer production system, including fertilizer filling equipment, fertilizer bag sealing equipment, and flat bag equipment. The fertilizer filling equipment is used to fill fertilizer into the fertilizer bag, and the filled fertilizer bag passes through the belt conveyor Transported to the fertilizer bag sealing equipment for sealing, the sealed fertilizer bags are transported to the flat bag equipment through the belt conveyor to be sorted and leveled, and then transported to the storage warehouse by the belt conveyor;

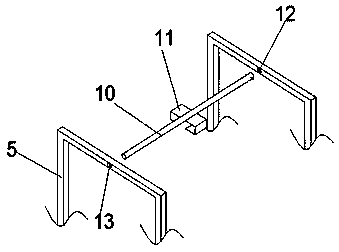

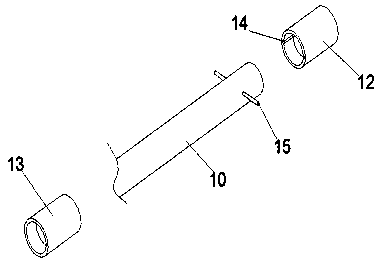

[0043] Such as Figure 1-7 As shown, the fertilizer filling equipment includes a conveyor belt 2, a frame 3, a filling head 9, a support 5, a buffer box 7, a hydraulic cylinder 6, and a storage box 8, and one side of the frame 3 is provided with The control box 4 installed by bolts, the conveyor belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com