A kind of amphiphobic filler, application and preparation method

An amphiphobic and heat-insulating coating technology, which can be applied to coatings and other directions, can solve the problems of easy shedding of hydrophobic and oleophobic groups, limited reactivity, and inappropriate modification of heat-insulating coatings, so as to improve reactivity and shorten the preparation period. , The effect of improving maintainability and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

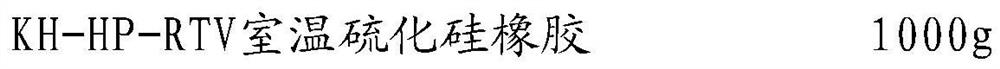

[0034] Proportion:

[0035] Glass cenospheres 200g

[0036] Tridecafluorooctyltriethoxysilane 20g

[0037] The preparation process of amphiphobic packing is as follows:

[0038] 1. Weigh 200g of glass hollow microspheres, place them in a container, heat up to 100-120°C in an oven, keep warm for 2-3 hours, remove the water vapor adsorbed on the surface of the hollow microspheres, and then raise the temperature at a rate of 5-10°C / min to 300℃, keep warm for 4~5h;

[0039] 2. Weigh 20g of tridecafluorooctyltriethoxysilane and place it in a boiling drier with a reflux device at the top. Adjust the temperature of the hot air to 150°C. After the temperature is stable, pour it into the above-mentioned heated glass hollow micro Beads are discharged after 4 hours of reaction in the boiling dryer, and the filler with surface amphiphobic properties is obtained.

[0040] The amphiphobic filler obtained in this example is added to the KH-HP-RTV room temperature vulcanizing silicone rub...

Embodiment 2

[0049] Proportion:

[0050] Silica hollow microspheres 500g

[0051] Heptadecafluorodecyltriethoxysilane 75g

[0052] The preparation process of amphiphobic packing is as follows:

[0053] 1. Weigh 500g of silica hollow microspheres, place them in a container, heat up to 100-120°C in an oven, keep warm for 2-3 hours, remove the water vapor adsorbed on the surface of the hollow microspheres, and then increase the temperature at a rate of 5-10°C / min Raise the temperature to 400°C and keep it warm for 4-5 hours;

[0054] 2. Weigh 75g of decafluorodecyltriethoxysilane and place it in a boiling drier with a reflux device at the top, adjust the temperature of the hot gas to 180°C, and pour the above-mentioned heated silica from the feeding port after the temperature is stable The hollow microspheres are discharged after 4 hours of reaction in the boiling dryer, and the thermal insulation filler with surface amphiphobic properties is obtained.

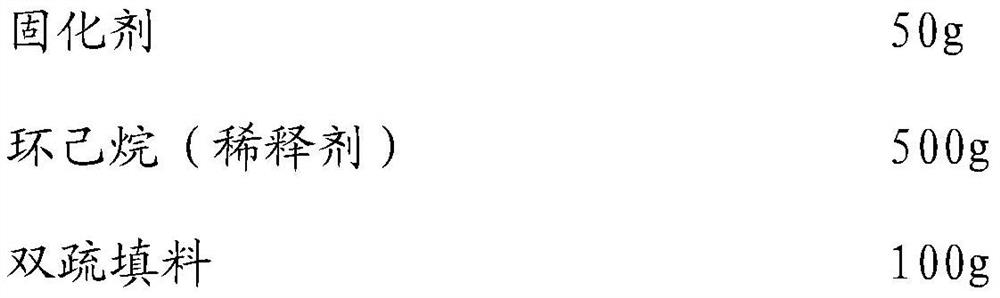

[0055] The amphiphobic filler obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com