A kind of train hub steering self-correcting assembly

A train wheel and self-calibration technology, which is applied in the field of rail transit, can solve problems that affect the normal steering of trains, affect the ride experience, and aggravate train bumps, etc., so as to improve the ride experience, improve the squeeze effect, and extend the maintenance cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

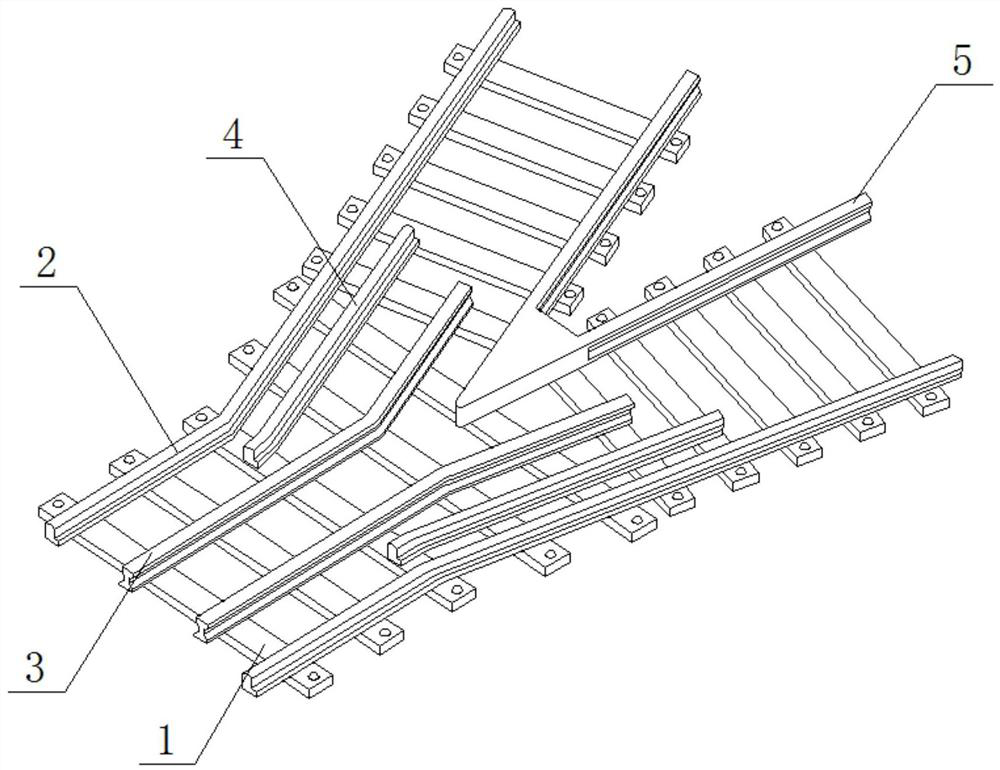

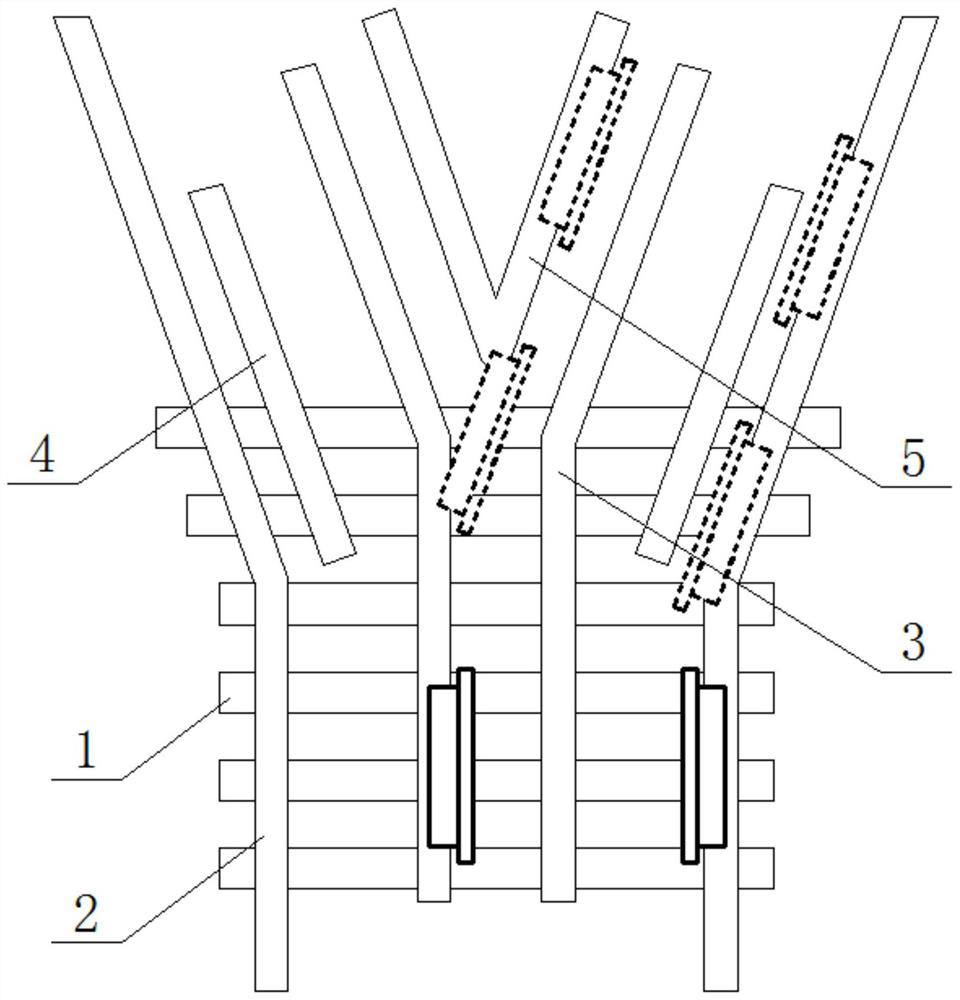

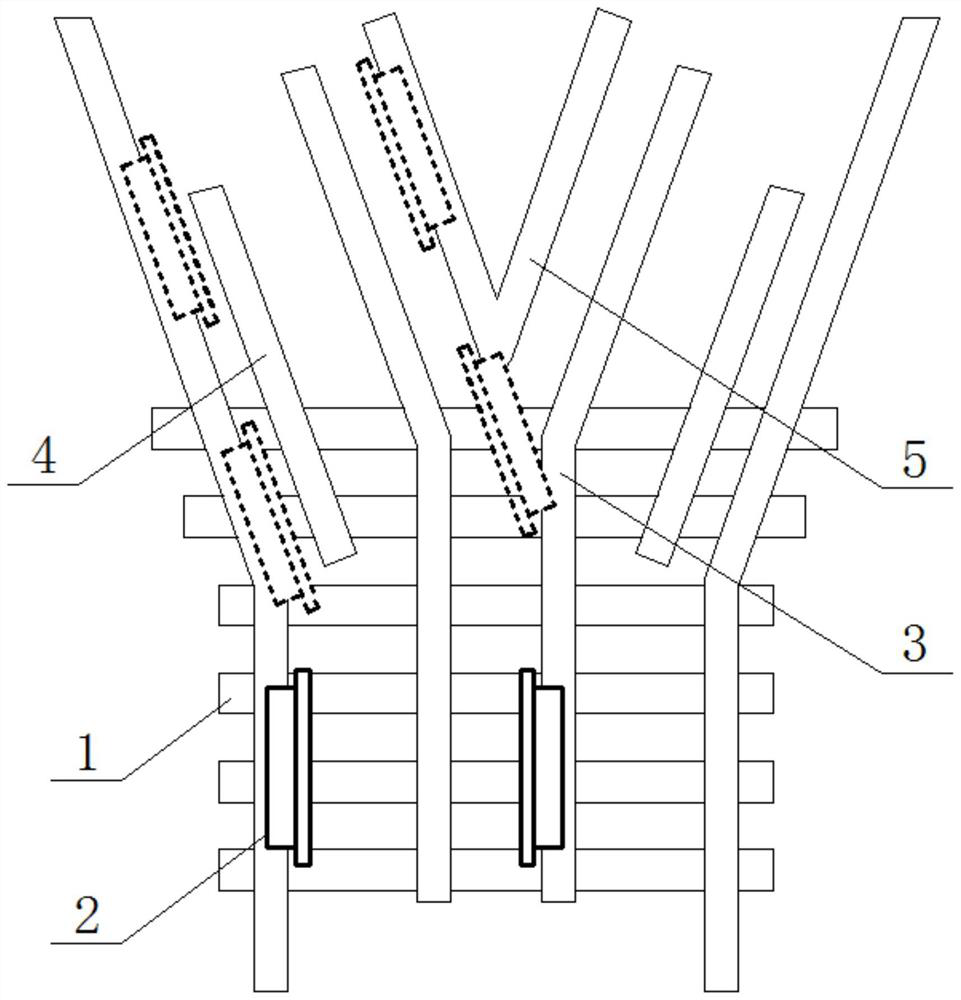

[0033] See Figure 4-8 , A train wheel steering self-correcting assembly, including sleepers 1 pre-installed on the ground and basic rails 2, inner curved rails 3, outer curved rails 4, and straight-point rails 5 conventionally arranged on the upper surface of the sleepers. The junction of the curved rail 3 and the straight tip rail 5 is fixedly provided with an energy dissipating gasket 6 on the surface of the sleeper 1, and the sleeper 1 is fixedly provided with a limit steel frame 7 at both ends of the energy dissipating gasket 6, and The limit steel frame 7 is close to the outer side wall of the straight rail 5;

[0034] The junction end of the inner curved guide rail 3 and the straight tip rail 5 is a solid arrangement, the inner curved guide rail 3 is provided with a rectangular placement groove 301 on one end surface close to the straight tip rail 5, and the bottom of the inner curved guide rail 3 is provided with three A limit slot 302 that penetrates the placement slot ...

Embodiment 2

[0043] See Picture 9 with Picture 10 The difference from the first embodiment is that the material of the coil 10 can also be a copper annular ring, and the length of the effective cutting magnetic field of the coil 10 is equal to the length of the permanent magnet 14, which can be selectively used according to the speed and quality of the train This setting reduces the overall impedance of the loop, and at the same time enhances the induced current generated by the loop. (The conductivity of copper is relatively stronger than that of iron, and the magnitude of the induced current increases with the number of cutting magnetic lines. This is current technology).

[0044] The working principle of the first embodiment and the second embodiment:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com