A heat storage element for high-flow, high-temperature, high-pressure, and high-speed gas environments

A high-temperature, high-pressure, high-speed gas technology, which is used in measurement devices, aerodynamic tests, and machine/structural component testing. , to achieve the effect of improving reliability and wind tunnel test efficiency, ensuring the cleanliness of the test air flow, and ensuring the safe operation of the wind tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

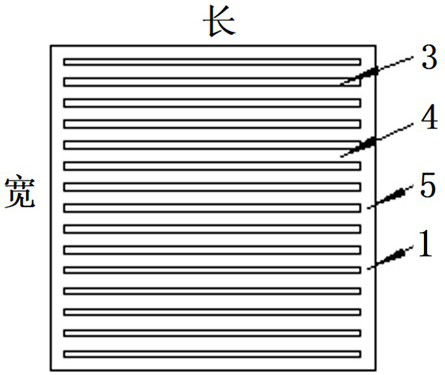

[0042] Such as Figure 1a , Figure 1b , Figure 1c , figure 2 As shown, the basic shape body 1 of the present embodiment is a cuboid with a length of 100 mm * a width of 100 mm * a height of 150 mm; times, the gap ratio is 0.33; the depth of the gap 3 of the grid is 150 mm, and the thickness of the outer wall 5 is 5 mm.

[0043] The basic shape 1 of this embodiment is processed by precision casting, and the 3mm gap can be cast directly, or it can be casted with a 12mm gap first, and then inserted and welded with a 6mm grating.

[0044] The basic body 1 and matching block 2 of this embodiment are used for image 3 , Figure 4 The regenerative heater shown is composed of an electric heating element, a regenerative element, a heat insulation layer, and a heater shell.

[0045] The arrangement of the basic body 1 and the matching block 2 in this embodiment is shown in Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com