Concrete vibrating device and method

A vibrating device and concrete technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of increasing manufacturing cost, affecting construction progress, increasing weight, etc., so as to reduce equipment manufacturing cost, improve construction efficiency, and reduce the number of installations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

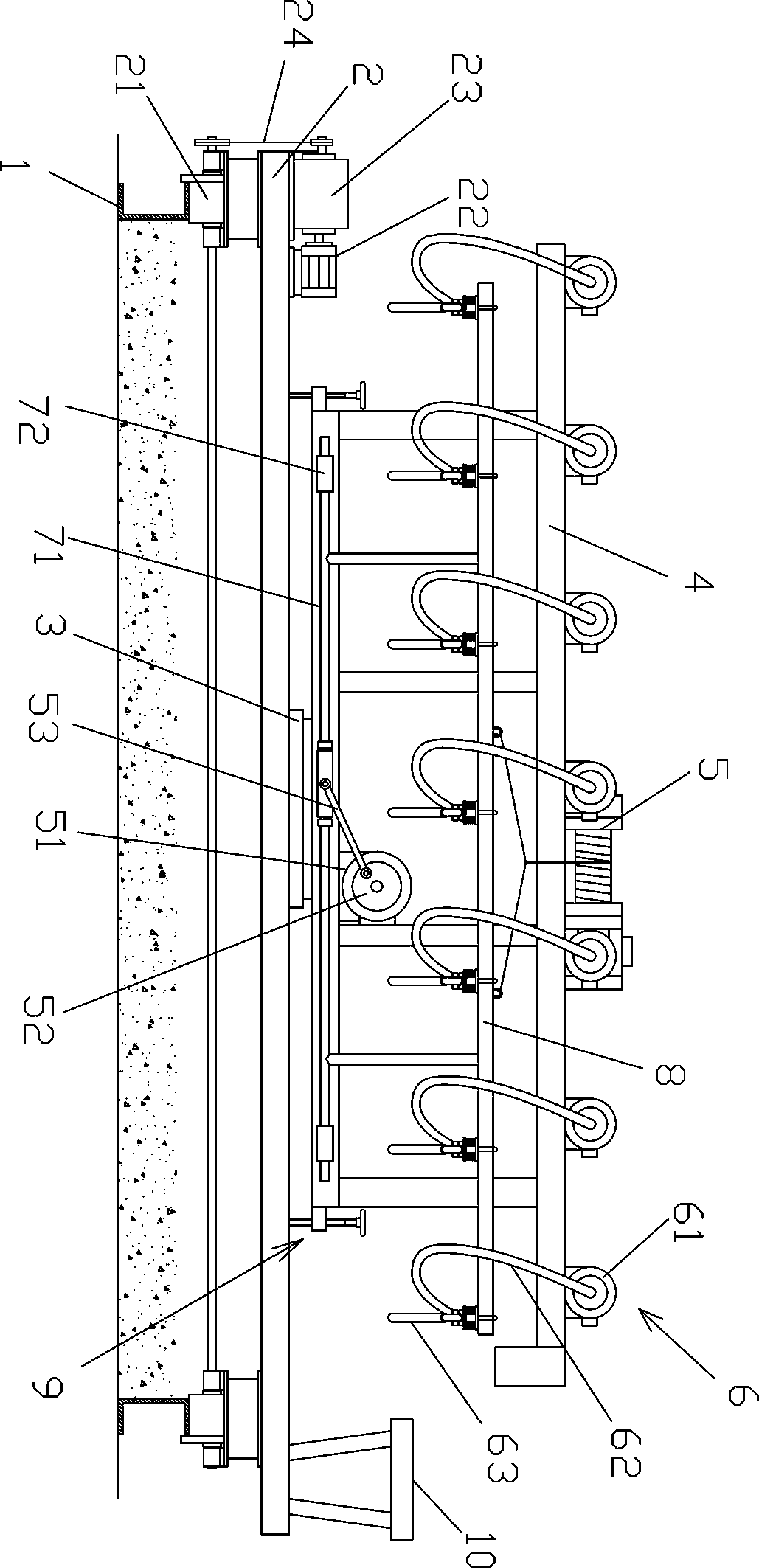

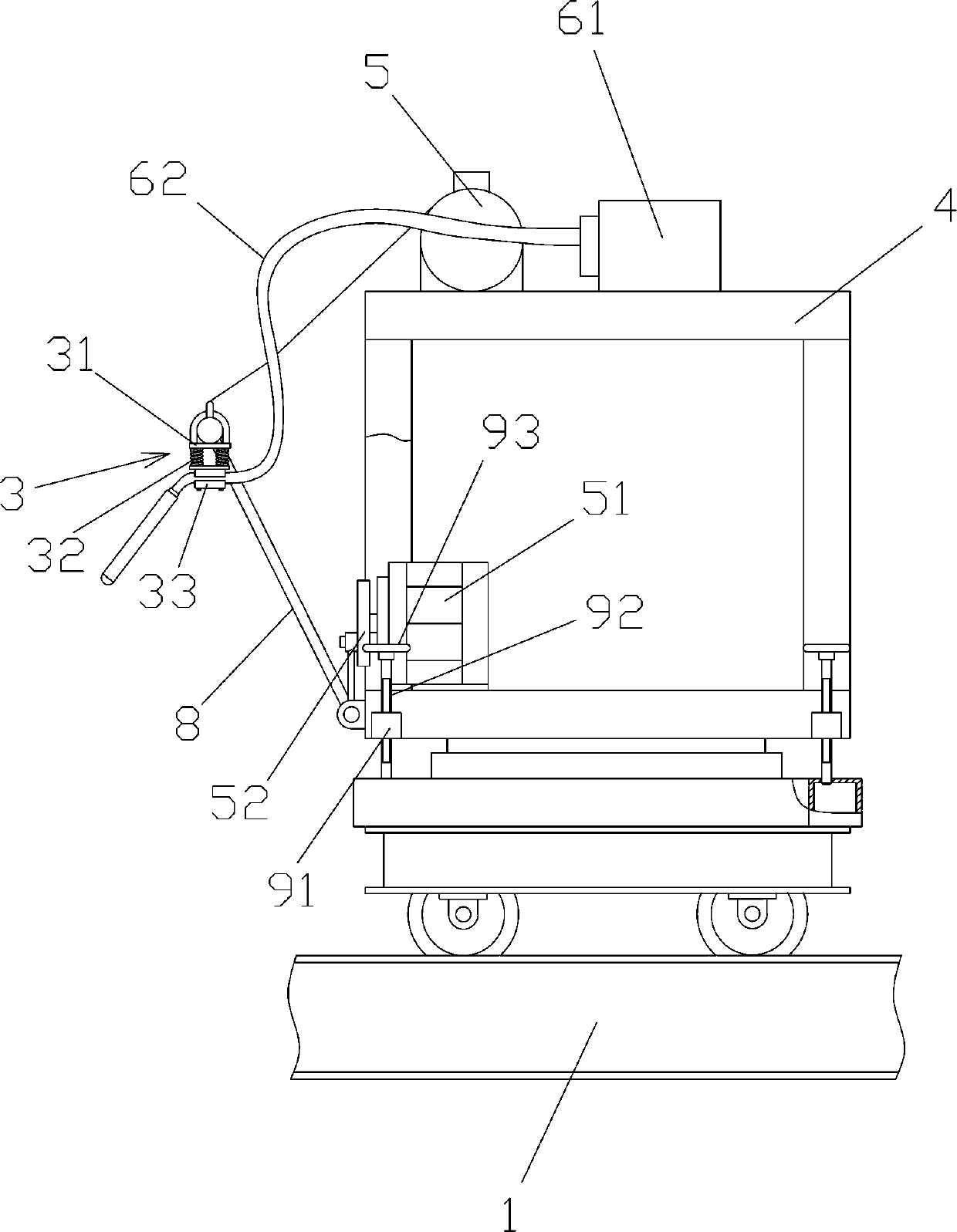

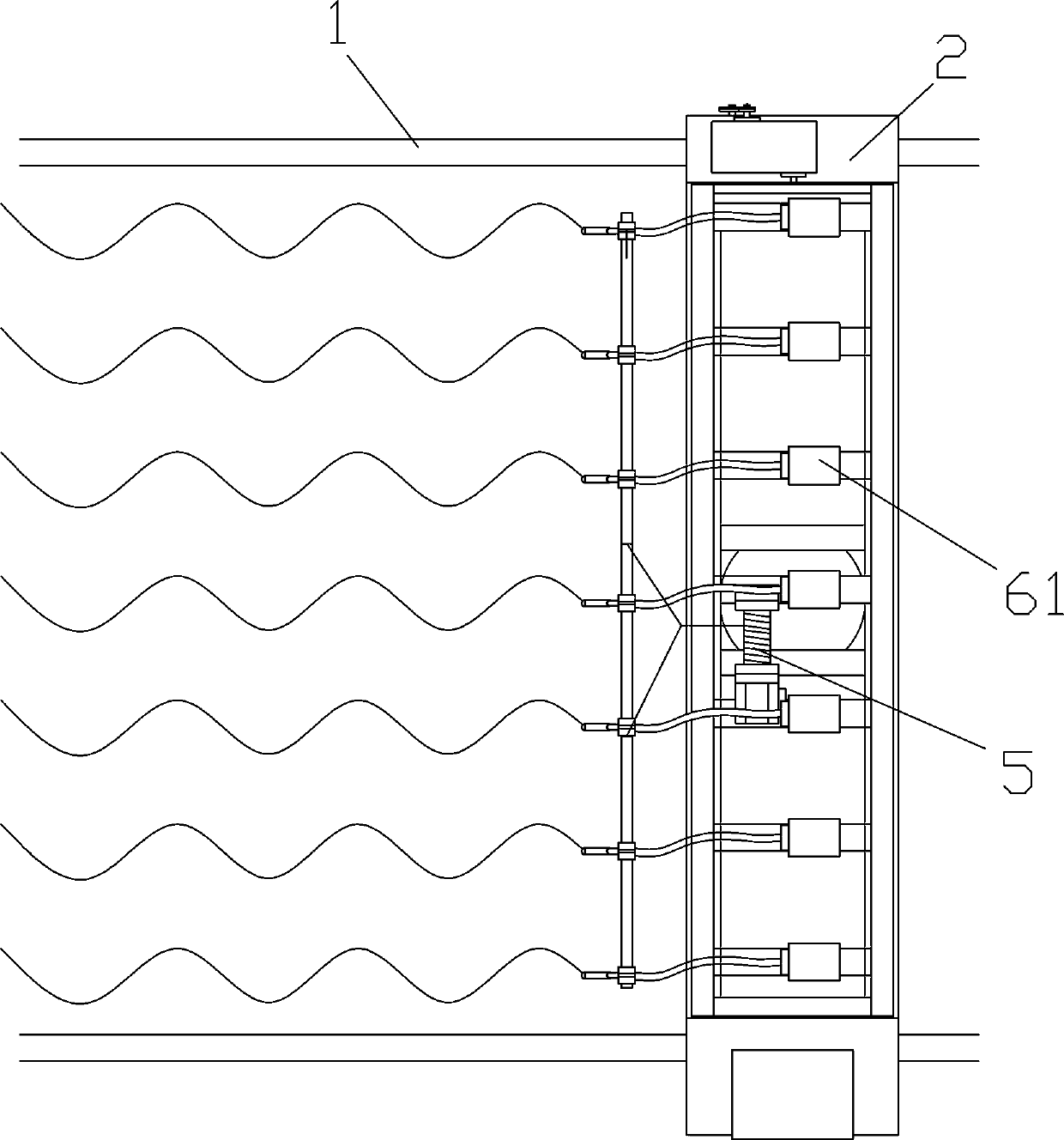

[0022] Such as Figures 1 to 3 As shown, a concrete vibrating device includes a bottom frame 2, on which a roller 21 and a travel motor 22 are installed, and the travel motor 22 is connected to the roller 21 through a speed reducer 23 and a sprocket transmission mechanism 24, and also includes Frame 4 and overturning frame 8, the middle part of frame 4 is connected with bottom frame 2 through slewing bearing 3, the lower end of overturning frame 8 is hinged on the lower end of frame 4, hoist machine 5 and multiple plug-in vibrators 6 are installed on frame 4, plug-in type Vibrator 6 comprises vibrating motor 61, flexible shaft tube 62 and vibrating pen 63, vibrating motor 61 is installed on the frame 4, vibrating pen 63 one end is connected overturn frame 8 upper ends by damping device 3, hoist 5 wire ropes connect overturn frame 8.

[0023] In the present invention:

[0024] The walking motor 22 can adopt the YE2-100 three-phase asynchronous motor produced by "Linqing Xingye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com