Novel excavator bucket

A kind of excavator, a new type of technology, applied in the direction of mechanically driven excavator/dredger, earth mover/shovel, construction, etc., can solve the problems of time-consuming and multi-process, so as to avoid the excavation process, speed up the excavation progress, The effect of saving digging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

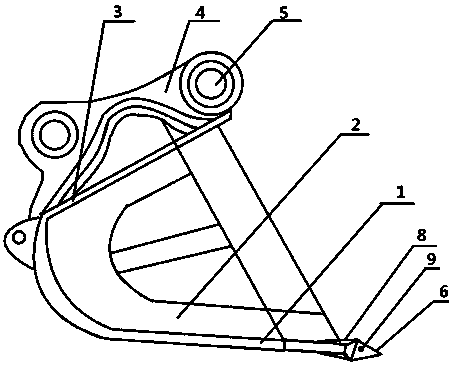

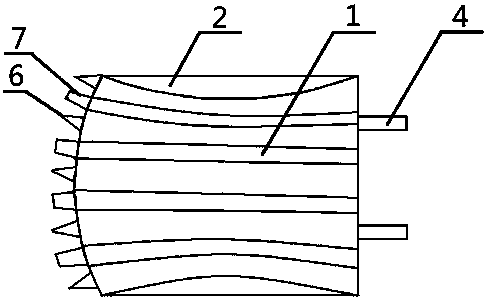

[0018] A new type of excavator bucket, including a bottom plate 1, a side plate 2, a cladding plate 3, a hinge plate 4, a torque tube 5, bucket teeth 6 and a hydraulic breaker 7; both sides of the bottom plate 1 are provided with side plates 2; the cladding plate 3 is arranged on the upper connection portion of the base plate 1; the base plate 1, the side plate 2 and the cladding plate 3 cooperate to form a bucket; the lower part of the cladding plate 3 is fixedly connected to the base plate 1; the Two hinge plates 4 are arranged in parallel on the upper part of the cladding plate 3; two groups of torque tubes 5 are horizontally arranged on the hinge plate 4; a tooth seat 8 is arranged on the lower end of the base plate 1; the bucket The tooth 6 is connected with the tooth seat 8 through the tooth pin 9; the hydraulic breaker 7 is arranged under the bottom plate 1 .

Embodiment example 2

[0020] A new type of excavator bucket, including a bottom plate 1, a side plate 2, a cladding plate 3, a hinge plate 4, a torque tube 5, bucket teeth 6 and a hydraulic breaker 7; both sides of the bottom plate 1 are provided with side plates 2; the cladding plate 3 is arranged on the upper connection portion of the base plate 1; the base plate 1, the side plate 2 and the cladding plate 3 cooperate to form a bucket; the lower part of the cladding plate 3 is fixedly connected to the base plate 1; the Two hinge plates 4 are arranged in parallel on the upper part of the cladding plate 3; two groups of torque tubes 5 are horizontally arranged on the hinge plate 4; a gear seat 8 is arranged on the lower end of the base plate 1; the bucket The tooth 6 is connected with the tooth seat 8 through the tooth pin 9; the hydraulic breaker 7 is arranged under the bottom plate 1 .

[0021] The base is provided with a groove, and the hydraulic breaker 7 is arranged at the groove.

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com