Method for calculating the cohesive force between horizontal layered surrounding rock layers of a simply supported beam structure

A calculation method and technology of simply supported beams, applied in calculation, design optimization/simulation, instruments, etc., can solve problems such as ignoring the interlayer cohesion of the roof rock mass, poor agreement between the model and the actual situation, and affecting construction costs and progress, etc. problems, to achieve the effect of simple and easy-to-understand models, reduce construction costs, and improve excavation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and engineering examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

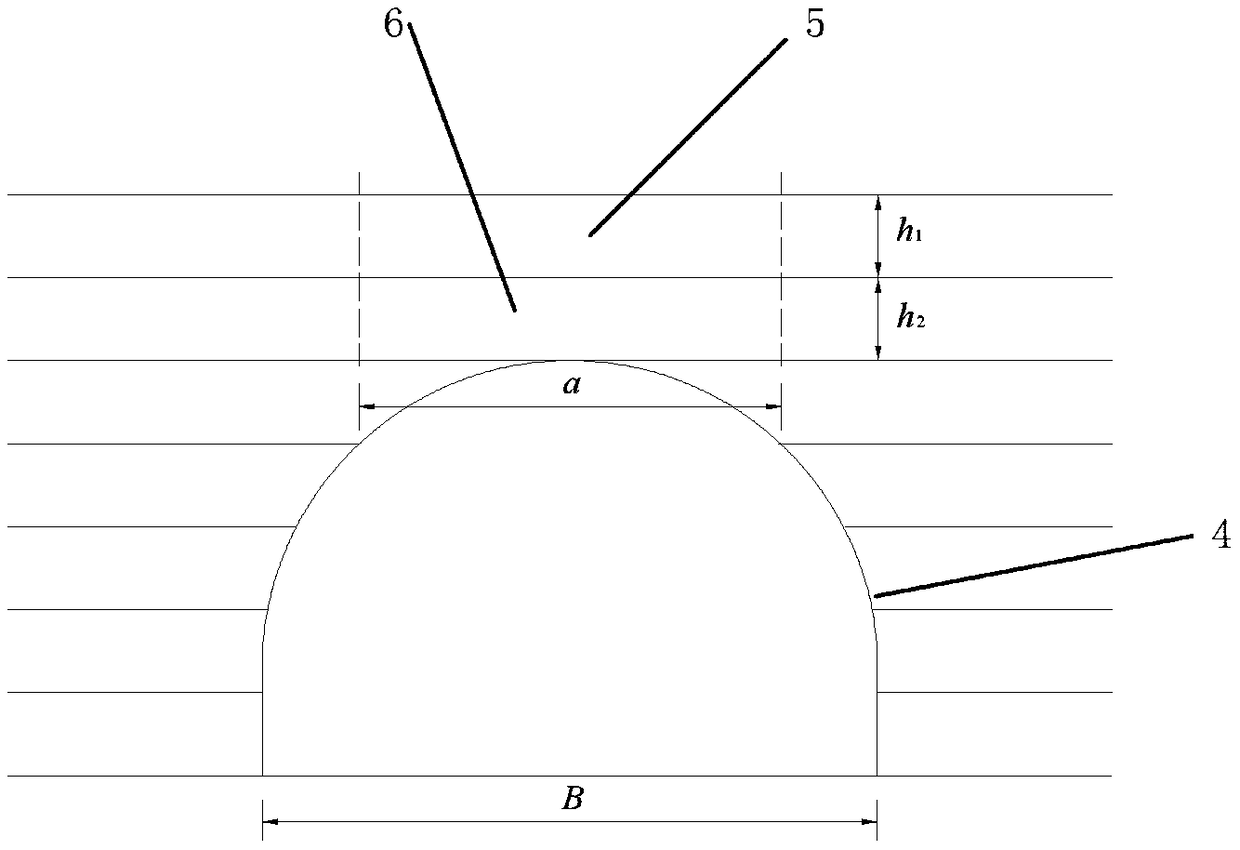

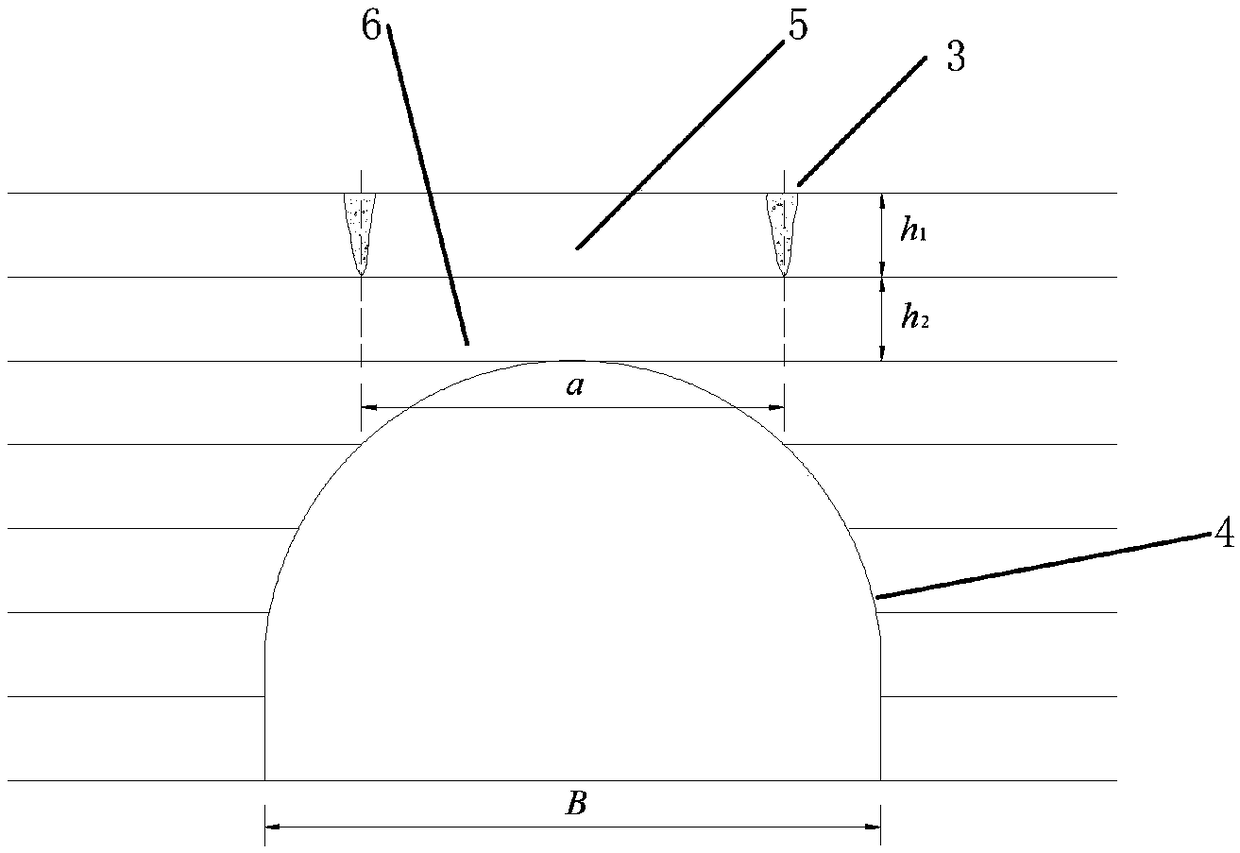

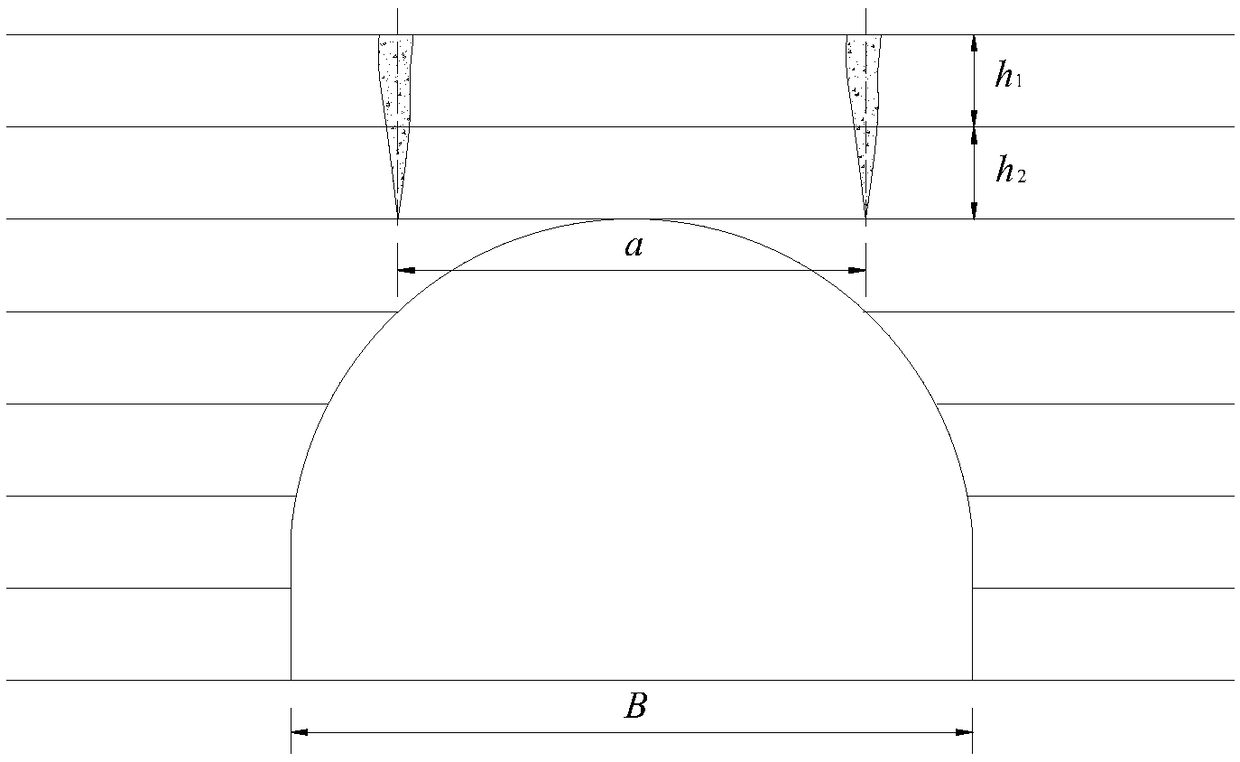

[0039] Figure 1-3 The schematic diagrams of the surrounding rock sections in the initial stage, intermediate stage, and later stage of tunnel excavation are given. 5 and 6 in the figure represent the upper rock mass and the lower rock mass respectively. Indicates the tunnel profile.

[0040] figure 1 In the initial stage of tunnel excavation, the surrounding rock is less disturbed, and the rock masses at both ends of the tunnel roof still have good integrity. At this time, the rock masses above the roof are constrained by the upper and lower strata It cannot be rotated, nor can it move up and down, left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com