Vertical shaft shield tunneling machine and cutterhead system thereof

A technology of shield machine and cutter head, applied in shaft equipment, well sinking, mining equipment and other directions, can solve the problems of slow excavation, unfavorable use, low degree of mechanization, etc., and achieve the effect of maintaining stability and stabilizing the shaft wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

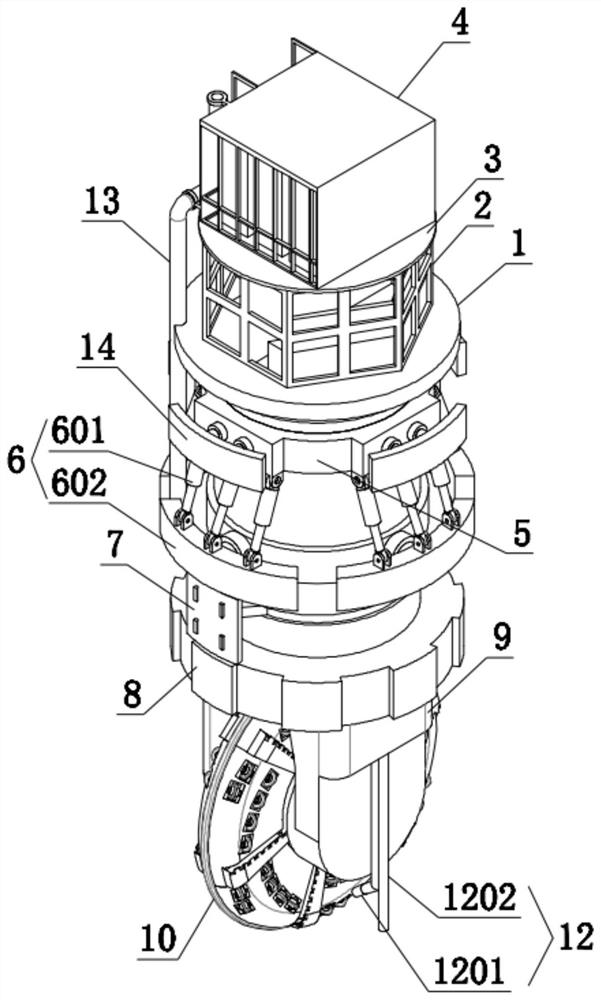

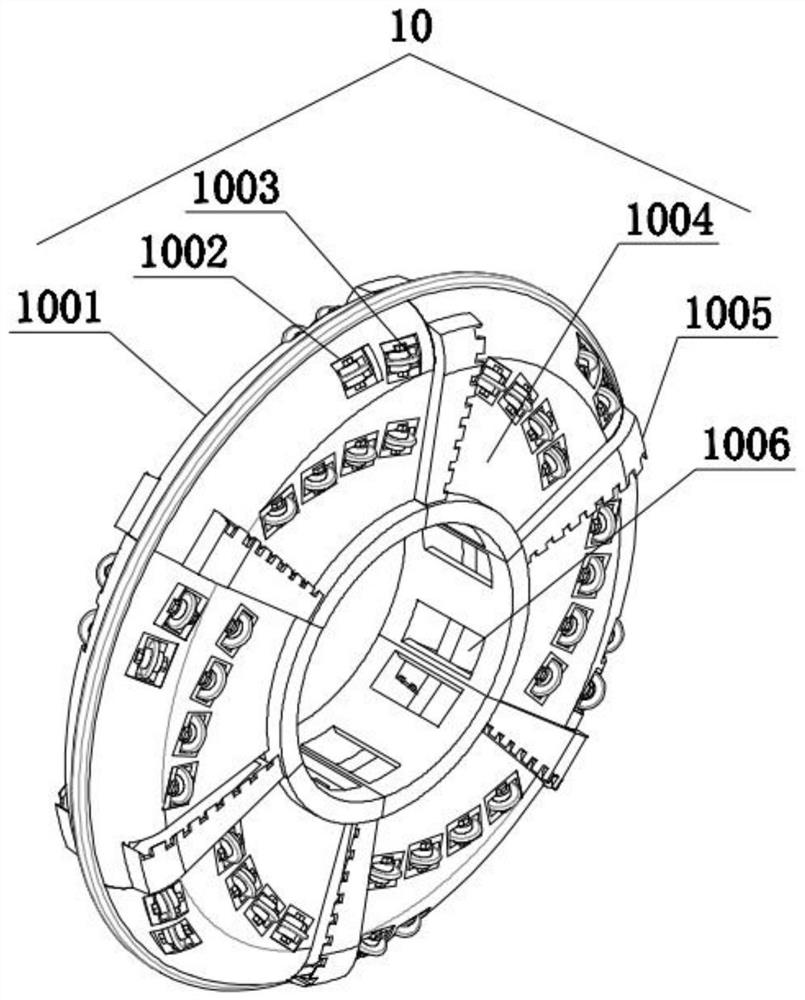

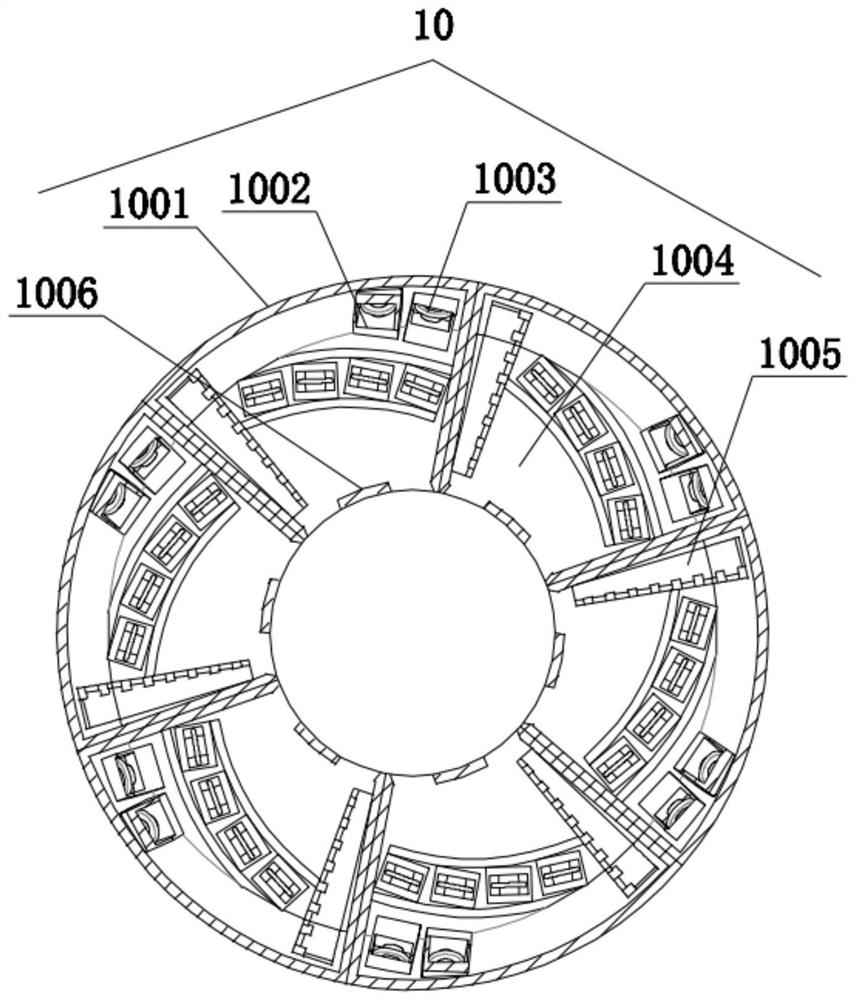

[0033] see Figure 1-4, a shaft shield machine and its cutter head system, including a working platform 1, an operating room 2 is fixedly installed on the top of the working platform 1, and a platform board 3 is fixedly connected to the top of the operating room 2, and the platform board 3 is fixedly installed with an equipment installation room 4, the bottom of the working platform 1 is fixedly connected with a main beam 5, and the outer upper end of the main beam 5 is fixedly installed with an expansion propulsion mechanism 6, and the outer side of the main beam 5 A segment assembly machine 7 is fixedly installed at the end, and a driving device 8 is fixedly installed at the outer lower end of the main beam 5. The bottom of the driving device 8 is fixedly connected with a mounting seat 9, and a tool is fixedly installed inside the mounting seat 9. A mechanism 10, a muck discharge mechanism 11 is fixedly installed in the inner center of the cutter mechanism 10, and a mud mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com