Communication tower prefabricated base and prefabrication technology thereof

A communication tower and process technology, applied in the field of prefabricated bases of communication towers and their prefabrication processes, can solve the problems of large amount of concrete pouring, prolonged construction period, low construction efficiency of communication towers, etc., so as to shorten the construction period, save time, and improve construction The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

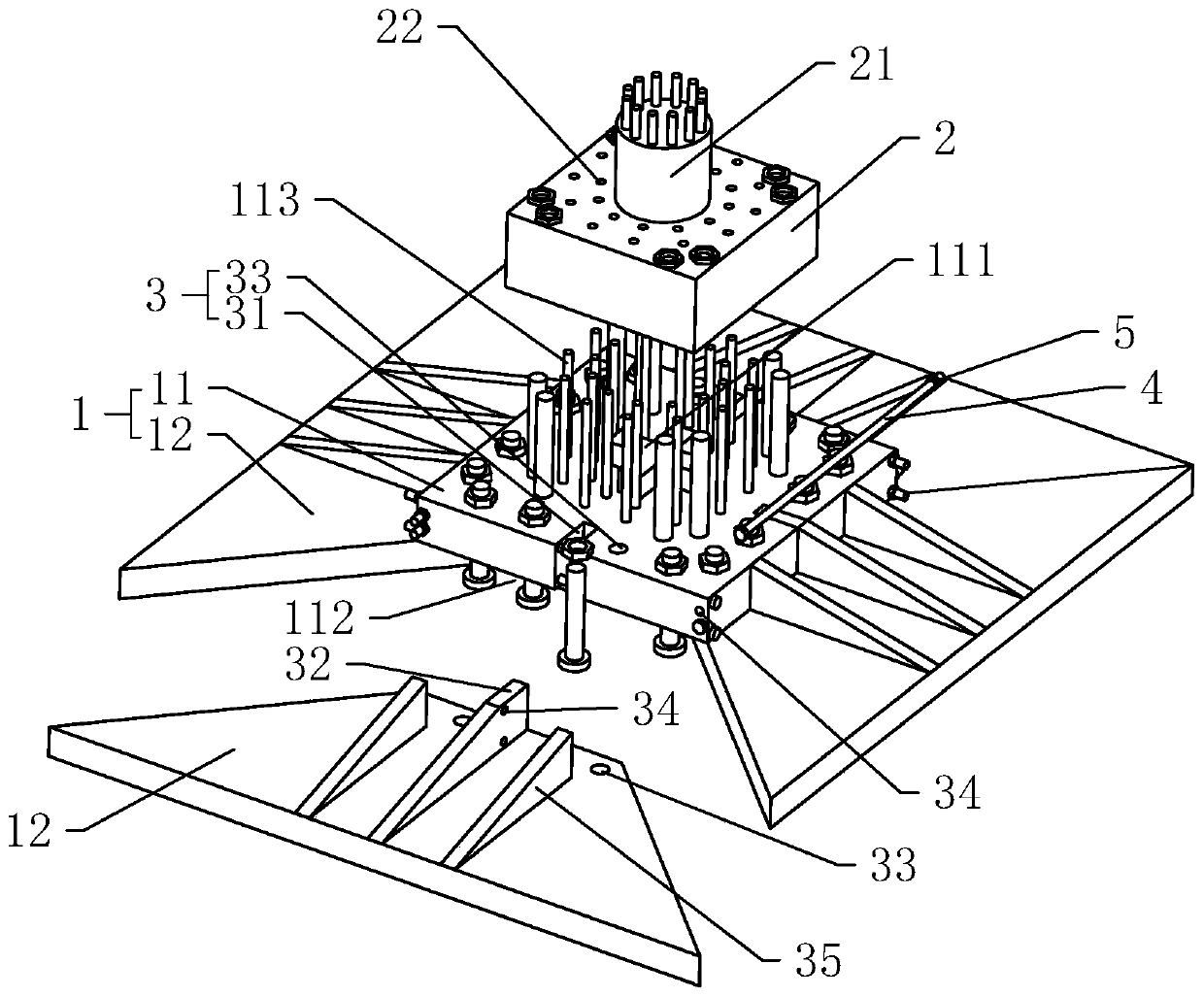

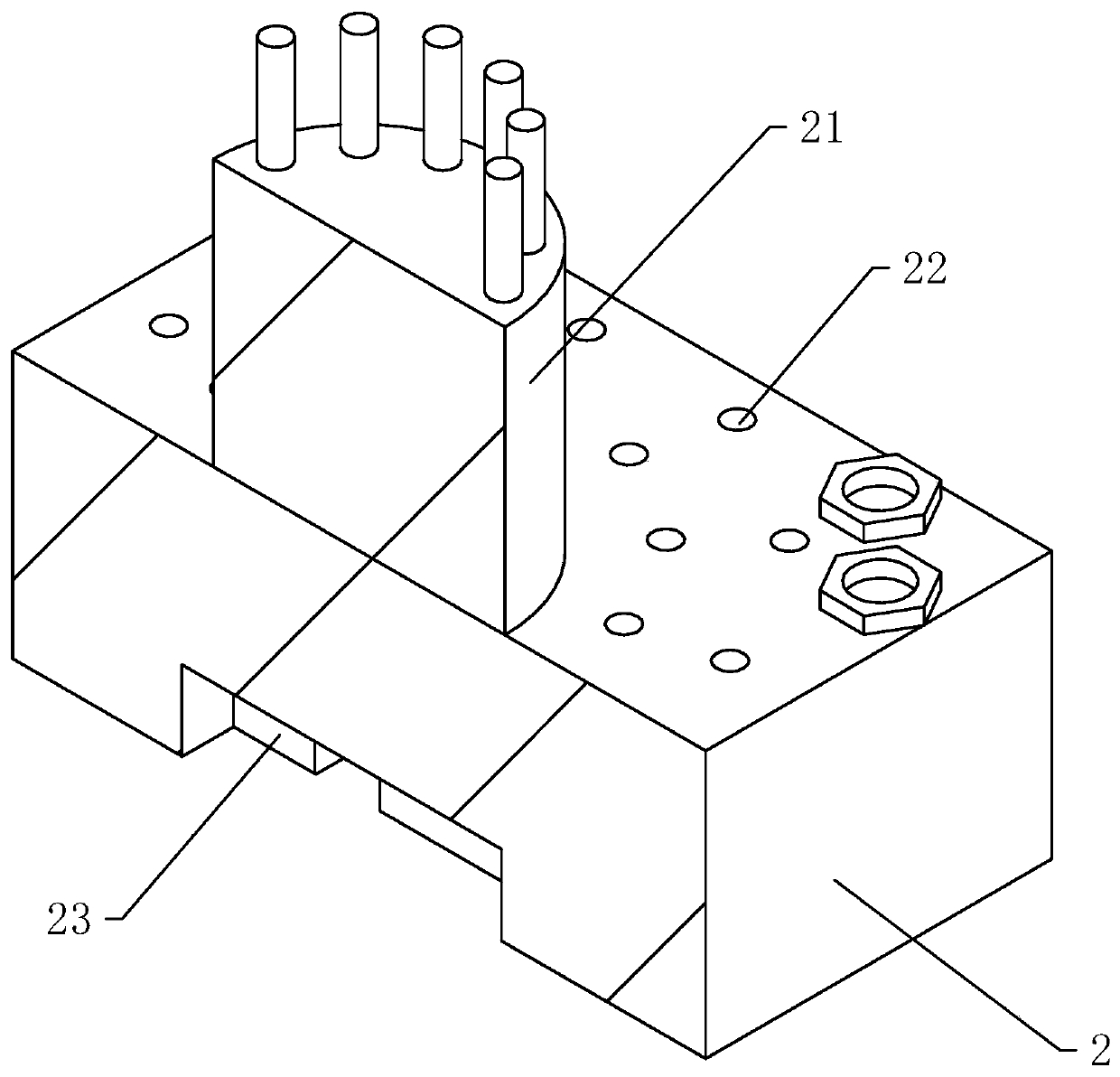

[0042] Such as figure 1 As shown, a prefabricated base of a communication tower includes a lower base body 1 and an upper base body 2. The lower base body 1 includes a support block 11 and a stabilizing plate 12. The support block 11 is in the shape of a square. A cross-shaped plug-in block 111 is integrally provided, and at least two groups of ground bolts 113 distributed in a concentric ring are embedded and welded in the support block 11. The plug-in block 111 is located at the center of the ground bolt 113, and is supported A surrounding mounting groove 112 is formed on the edge of the surface of the block 11 facing away from the plug-in block 111 .

[0043] The stabilizing plate 12 is in the shape of a trapezoidal plate, fixed on the supporting block 11 through the connecting structure 3 and located in the installation groove 112 .

[0044] The connection structure 3 includes a plate groove 31, a connecting plate 32, a vertical hole 33, a transverse hole 34, and a reinfo...

Embodiment 2

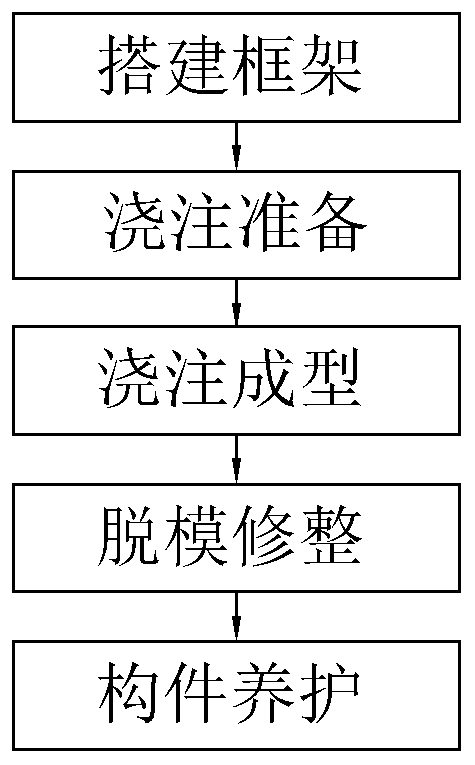

[0050] A prefabrication process for a prefabricated base of a communication tower, the steps comprising:

[0051] (1) To build the frame, it is first necessary to use steel bars to build two three-dimensional frames with a four-frame shape and a cross-perpendicular frame structure. In the three-dimensional frame structure, the larger one is used as the lower frame, and the lower The seat body is the subject of force. Another three-dimensional frame is used as the upper body frame, and the plate frame structure is used as a stable plate frame, and then at least two sets of ground bolts distributed in concentric rings are welded at the center above the lower body frame, and the embedded steel bars are welded in the center of the upper body frame As the steel frame of the socket column, the construction of the frame is completed.

[0052] After the steel frame is built, it is necessary to wrap the burlap net on the frame. The mesh diameter of the burlap net is 2~4mm. Before win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com