LED ceiling lamp

A technology for LED ceiling lamps and LED bulbs, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, lighting devices, etc., can solve problems such as large hole diameter, failure to fix normally, and damage to the fixing frame of LED lamps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

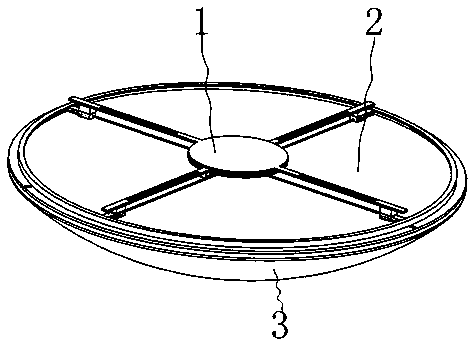

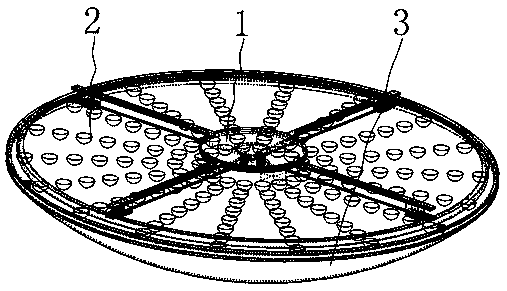

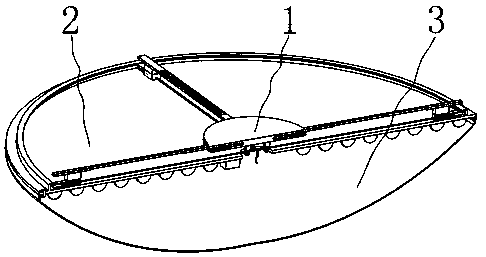

[0044] like figure 1 , 2 As shown, it includes a suspension mechanism 1, a lamp panel 2, and a lampshade 3, among which Image 6 As shown, the lower side of the lamp panel 2 has evenly distributed LED bulbs 33 and a control module 6 for controlling the LED bulbs 33, as Figure 7 As shown, the central position of the lamp panel 2 is provided with a shaft hole 7 that penetrates up and down; the lamp panel 2 is equipped with a lamp panel snap ring 9 and a chuck 10, as shown in image 3 , 4 As shown, the function of the lamp panel snap ring 9 is to fix the lamp panel 2 on the limit block 27 of the suspension mechanism 1 through the lamp panel snap ring 9; the function of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap