Testing device and method for the mechanical properties of inner yarn of ceramic matrix composite material

A composite material and testing device technology, which is used in the preparation of measuring devices, analytical materials, and testing samples, can solve problems such as unseen invention patents, and achieve the effects of convenient disassembly, strong applicability, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A device and method for testing the mechanical properties of yarns inside a ceramic matrix composite material proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

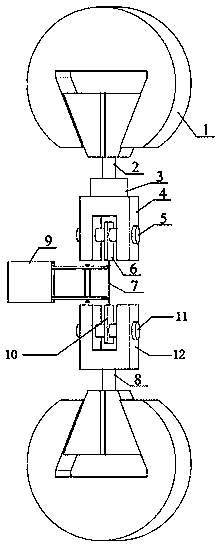

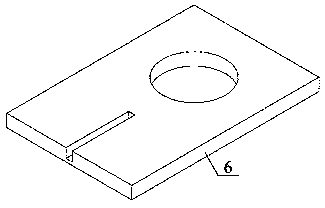

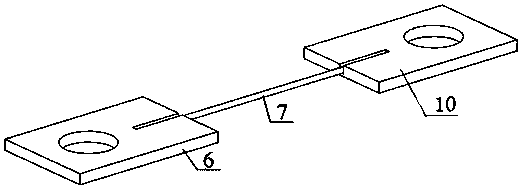

[0037] Such as figure 1As shown, the device for testing the internal yarn mechanical properties of ceramic matrix composites includes: a testing machine chuck 1, and there are two testing machine chucks 1, respectively clamping the upper round bar 2 and the lower round bar 8, and the upper round bar 2 Connected to the bottom of the upper U-shaped clamp block 4, the upper pin 5 passes through the two side arms of the upper U-shaped clamp block 4 and the upper reinforcement piece 6 at the same time, and the upper reinforcement piece 6 is suspended at the opening of the upper U-shaped clamp block 4, The upper reinforcement piece 6 is fixedly connected to one end of the matrix fiber bundle 7, the lower round rod 8 is connected to the bottom of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com