A kind of high-strength and high-plasticity cast magnesium alloy and preparation method thereof

A technology for casting magnesium alloys and high plasticity, which is applied in the field of magnesium alloys and their preparation, high-strength and high-plasticity casting magnesium alloys and their preparation fields, can solve the problems of inability to meet the requirements of military and civil applications, and achieves high strength, plasticity, and refinement. Grain, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

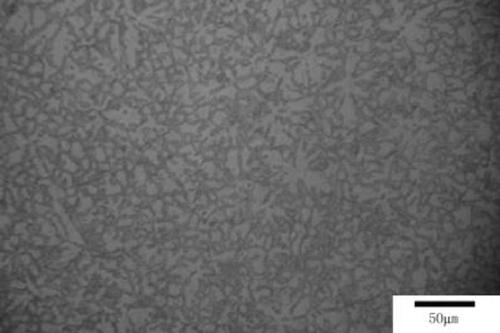

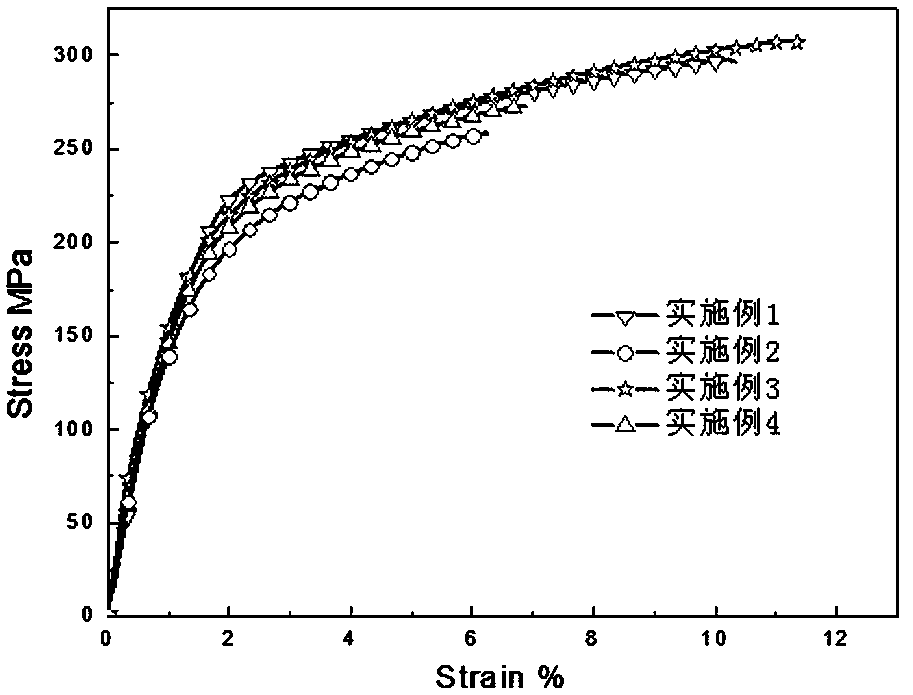

[0025] According to the percentage by weight of Zn 4.26%, Y 9.26%, Ca 0.48%, Mn 0.44%, proportioning the alloy, melting the ingot in a vacuum melting furnace, and feeding it with argon for protection. Among them, Zn and Y are added in the form of pure Zn, Mg-Y master alloy, Mg-Ca master alloy and Mg-Mn master alloy respectively; the mass fraction of Y in Mg-Y master alloy is 30%, and in Mg-Ca master alloy The mass fraction of Ca is 30%, and the mass fraction of Mn in the Mg-Mn master alloy is 3%. Keep warm at 820°C and stir with electromagnetic induction to fully melt the raw materials. After the alloy is completely melted, continue to stand at 750°C for 5 minutes. At the same time, the low-carbon steel metal mold was preheated to 250°C, and then a quick-drying high-temperature lubricating release agent was sprayed on the inner wall of the mold, and then poured to obtain the prepared sample. figure 1 It is the metallographic diagram of the cast magnesium alloy in this embodim...

Embodiment 2

[0028] According to the percentage by weight of Zn 4.47%, Y 9.31%, Ca 0.51%, Mn 0.66%, proportioning alloys, melting ingots in a vacuum melting furnace, and feeding argon for protection, the specific process is as in Example 1.

[0029] The tensile mechanical properties of the alloy were tested, and the test results showed that the alloy had good mechanical properties ( figure 2 ), the tensile strength is 270MPa, the yield strength is 205Mpa, and the elongation is 6.9%.

Embodiment 3

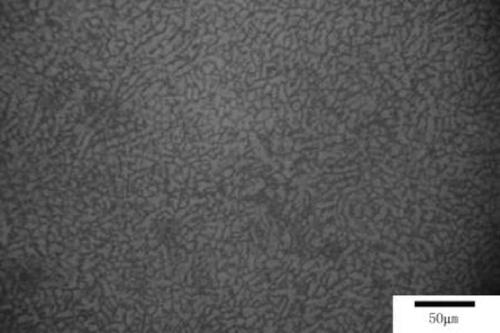

[0031] According to the percentage by weight of Zn 4.89%, Y 9.62%, Ca 0.49%, Mn 1.02%, proportioning alloys, melting ingots in a vacuum melting furnace, and feeding argon for protection, the specific process is as in Example 1.

[0032] The tensile mechanical properties of the alloy were tested, and the test results showed that the alloy had good mechanical properties, the tensile strength was 291MPa, the yield strength was 220Mpa, and the elongation was 10.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com