Shaping tool for shaping amorphous core and core shaping system

An amorphous iron core and tooling technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of high cost of human resources, difficult size control, low production capacity, etc., to ensure accurate size and appearance Consistency, reduce human resource costs, and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

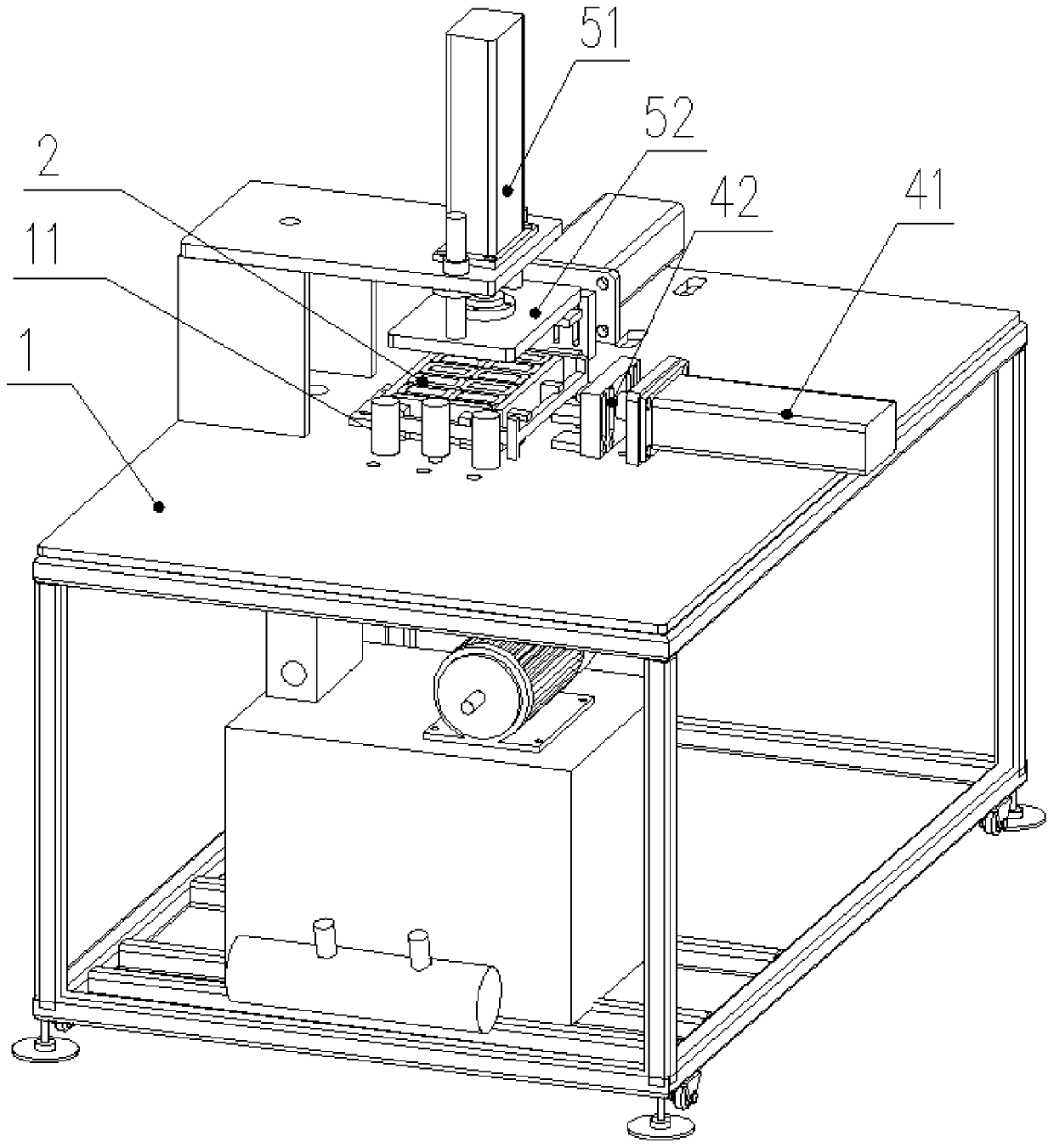

[0020] Such as figure 1 and figure 2 As shown, an iron core sizing system of the present invention includes a working table 1 on which a tooling station 11 for placing sizing tooling is arranged.

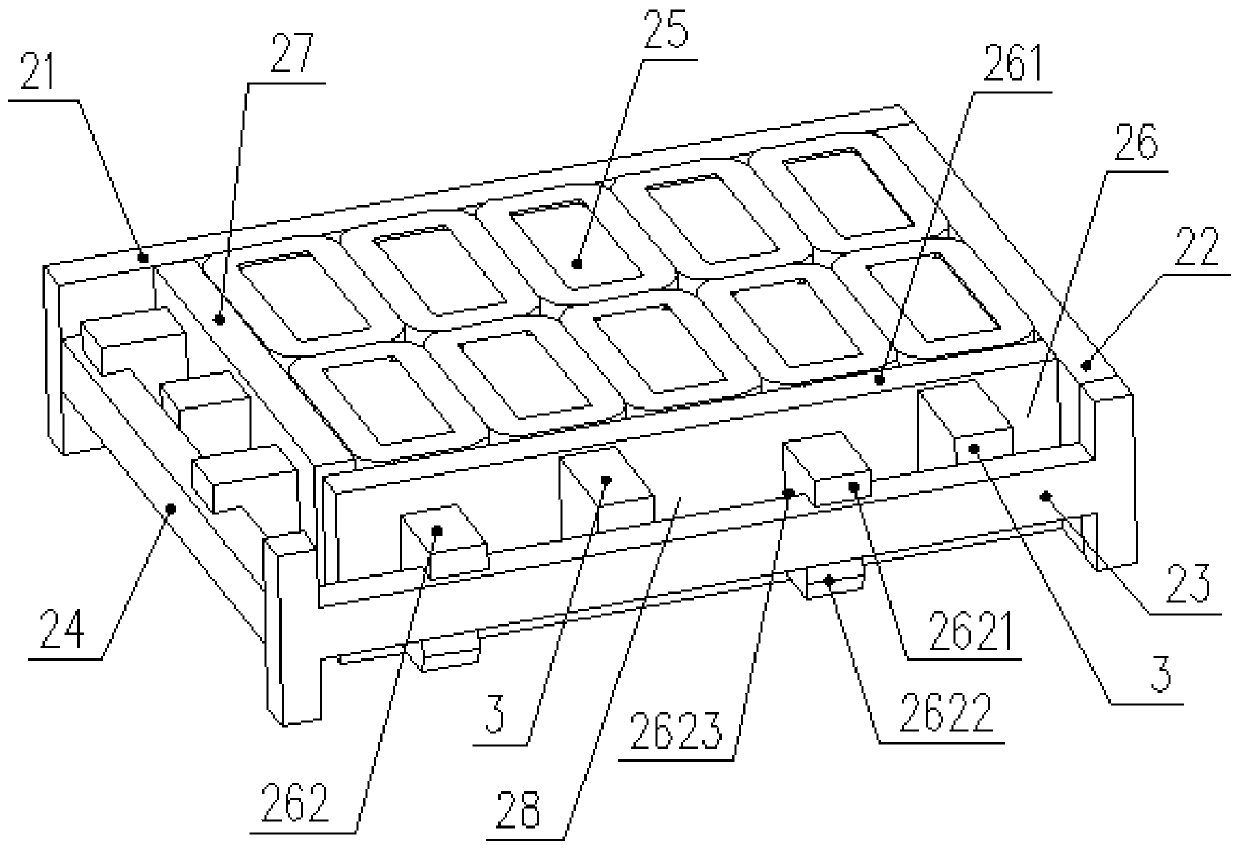

[0021] The sizing fixture includes a sizing fixture 2 and a positioning block 3, and the sizing fixture 2 includes an outer frame enclosed by long splints 21, short splints 22, long connecting rods 23 and short connecting rods 24 connected end to end. The inner side of the outer frame is formed with a rectangular inner cavity 25 for placing iron core workpieces; A short pressing plate 27 is provided on the side.

[0022] The long clamping plate 26 includes a long plate body 261 arranged parallel to the long splint 21 , and the long plate body 261 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com