Graphene/niobium pentoxide composite electrode material and preparation method thereof

A technology of niobium pentoxide and composite electrodes, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems affecting the three-dimensional structure of graphene transition metal oxide crystal structure, the influence of electrode materials on electrical properties, etc., and achieve shortened transmission route, good preparation reproducibility, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

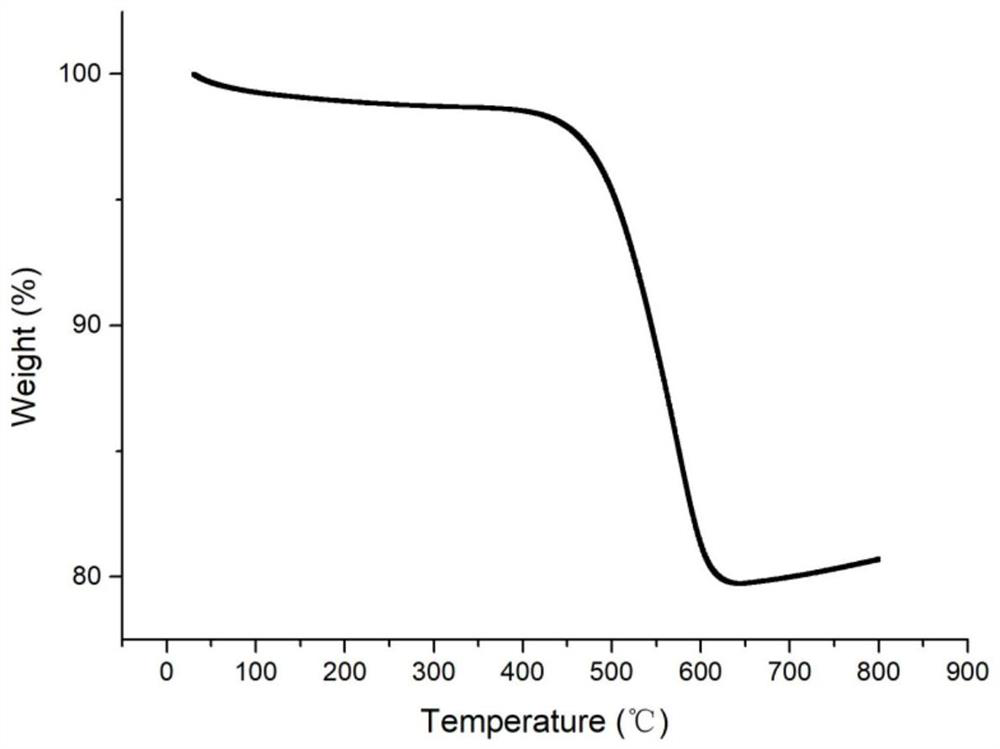

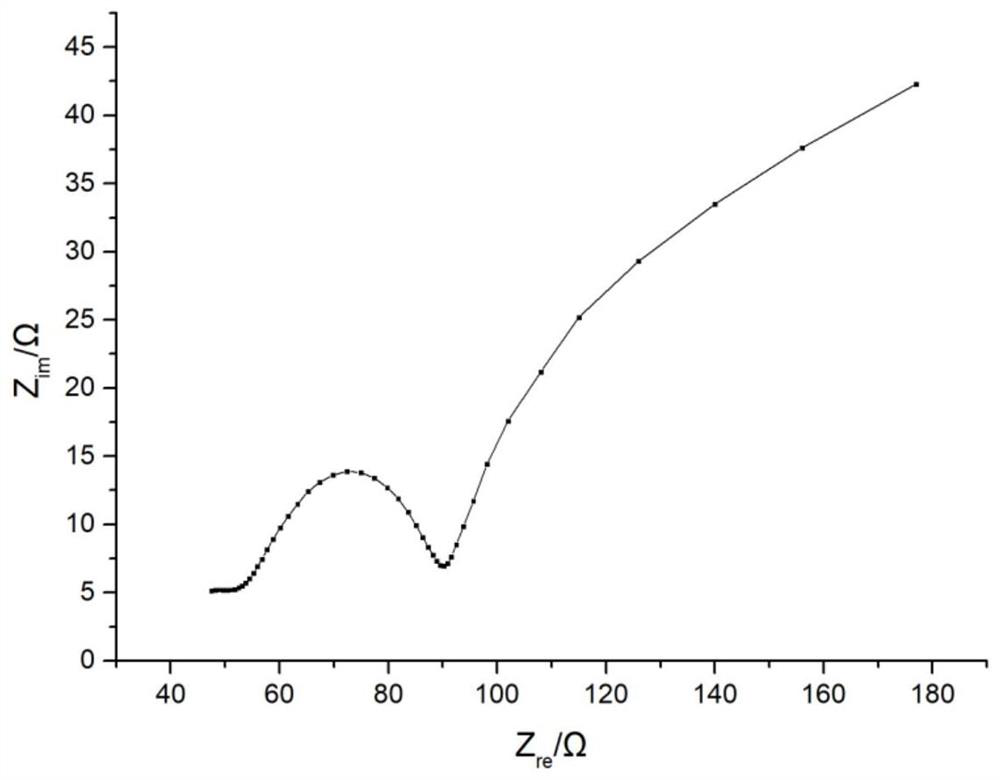

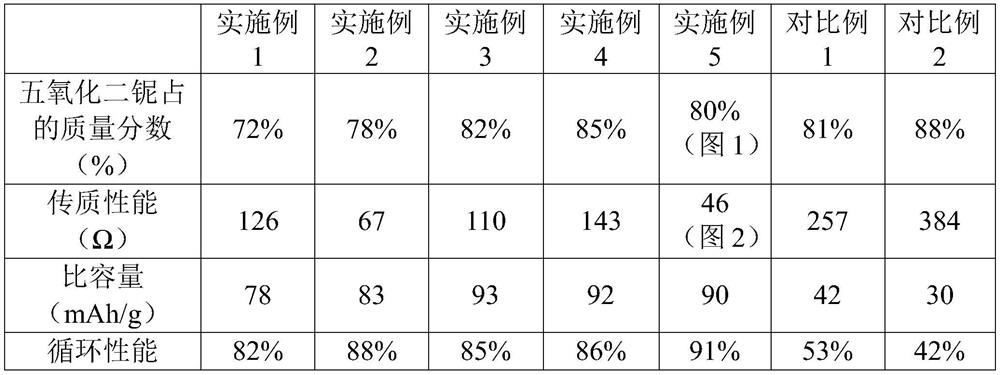

Examples

Embodiment 1

[0035] In the present embodiment, a method for preparing a graphene / niobium pentoxide three-dimensional composite electrode material, the steps are as follows:

[0036] (1) Add 0.3 g of N,N'-dicyclohexylcarbodiimide to 40 mL of graphene oxide dispersion with a concentration of 5.0 mg / mL, and under sufficient stirring, heat to 90 °C and reflux for 3 h.

[0037] (2) Dissolve 0.7 g of niobium pentachloride in 10 mL of absolute ethanol, then add it to the mixed solution in step (1), heat to 90° C. under sufficient stirring, and react under reflux for 1 h.

[0038] (3) 0.5 g of sodium ascorbate was added to the mixed solution in step (2), heated to 90° C. under sufficient stirring, and reacted under reflux for 1 h.

[0039] (4) The mixed solution prepared in step (3) was transferred to a 100 mL solvothermal reactor for reaction at 190° C. for 15 h. The solvothermal product was separated by suction filtration to obtain a solid, which was successively washed three times with deioniz...

Embodiment 2

[0042] In the present embodiment, a method for preparing a graphene / niobium pentoxide three-dimensional composite electrode material, the steps are as follows:

[0043] (1) Add 0.4 g of N,N'-dicyclohexylcarbodiimide to 50 mL of graphene oxide dispersion with a concentration of 4.0 mg / mL, and under sufficient stirring, heat to 90 °C and reflux for 3 h.

[0044] (2) Dissolve 0.8 g of niobium pentachloride in 10 mL of anhydrous ethanol, then add it to the mixed solution in step (1), heat to 90° C. under sufficient stirring, and react under reflux for 1 h.

[0045] (3) 0.5 g of sodium ascorbate was added to the mixed solution in step (2), heated to 90° C. under sufficient stirring, and reacted under reflux for 1 h.

[0046] (4) The mixed solution prepared in step (3) was transferred to a 100 mL solvothermal reactor for reaction at 190° C. for 15 h. The solvothermal product was separated by suction filtration to obtain a solid, which was successively washed three times with deioni...

Embodiment 3

[0049] In the present embodiment, a method for preparing a graphene / niobium pentoxide three-dimensional composite electrode material, the steps are as follows:

[0050] (1) Add 0.4 g of N,N'-dicyclohexylcarbodiimide to 50 mL of graphene oxide dispersion with a concentration of 4.0 mg / mL, and heat to 90 °C under sufficient stirring, and reflux for 3 h.

[0051] (2) Dissolve 1.0 g of niobium pentachloride in 15 mL of absolute ethanol, then add it to the mixed solution in step (1), heat to 90° C. under sufficient stirring, and react under reflux for 1 h.

[0052] (3) Add 0.5 g of sodium ascorbate to the mixed solution in step (2), under sufficient stirring, heat to 100° C., and perform reflux reaction for 1 hour.

[0053] (4) The mixed solution prepared in step (3) was transferred to a 100 mL solvothermal reactor for reaction at 190° C. for 15 h. The solvothermal product was separated by suction filtration to obtain a solid, which was successively washed three times with deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com