Numerical control machine tool for wood processing

A CNC machine tool and wood technology, which is applied to wood processing equipment, processing machines for manufacturing flat surfaces, fine planers, etc., can solve the problems of hidden dangers for the safety of operators, high labor intensity of operators, and low planing efficiency. , to achieve the effects of improved precision, high planing efficiency and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

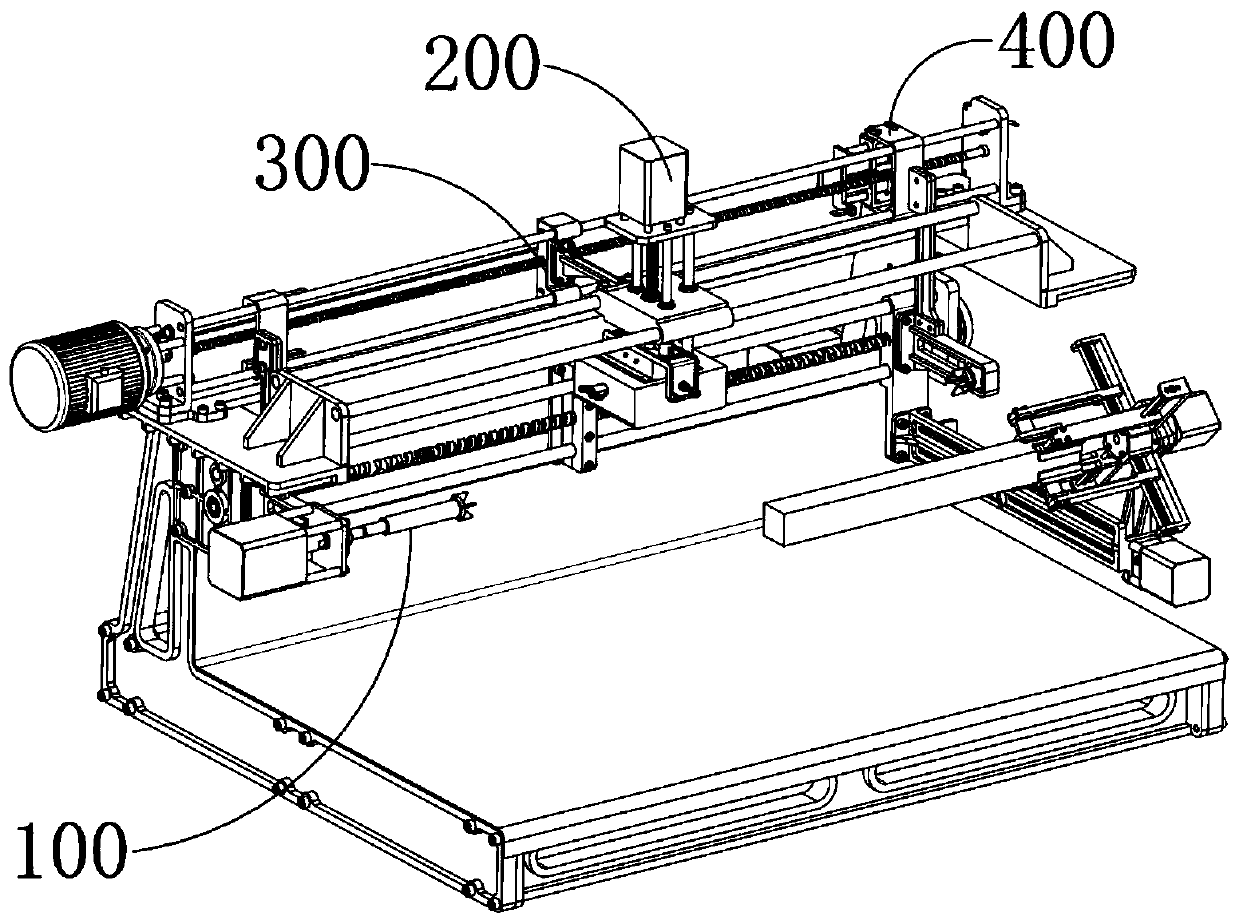

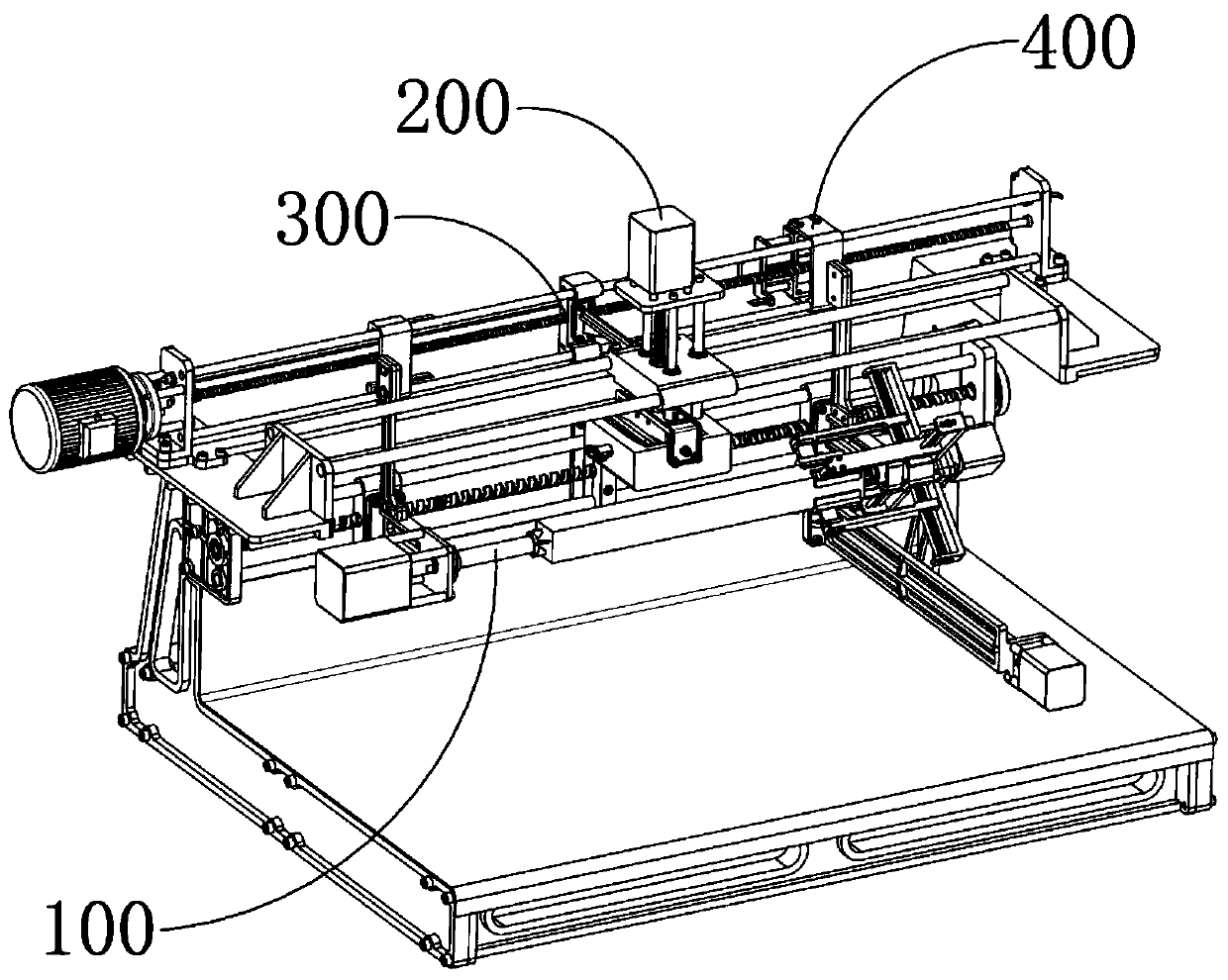

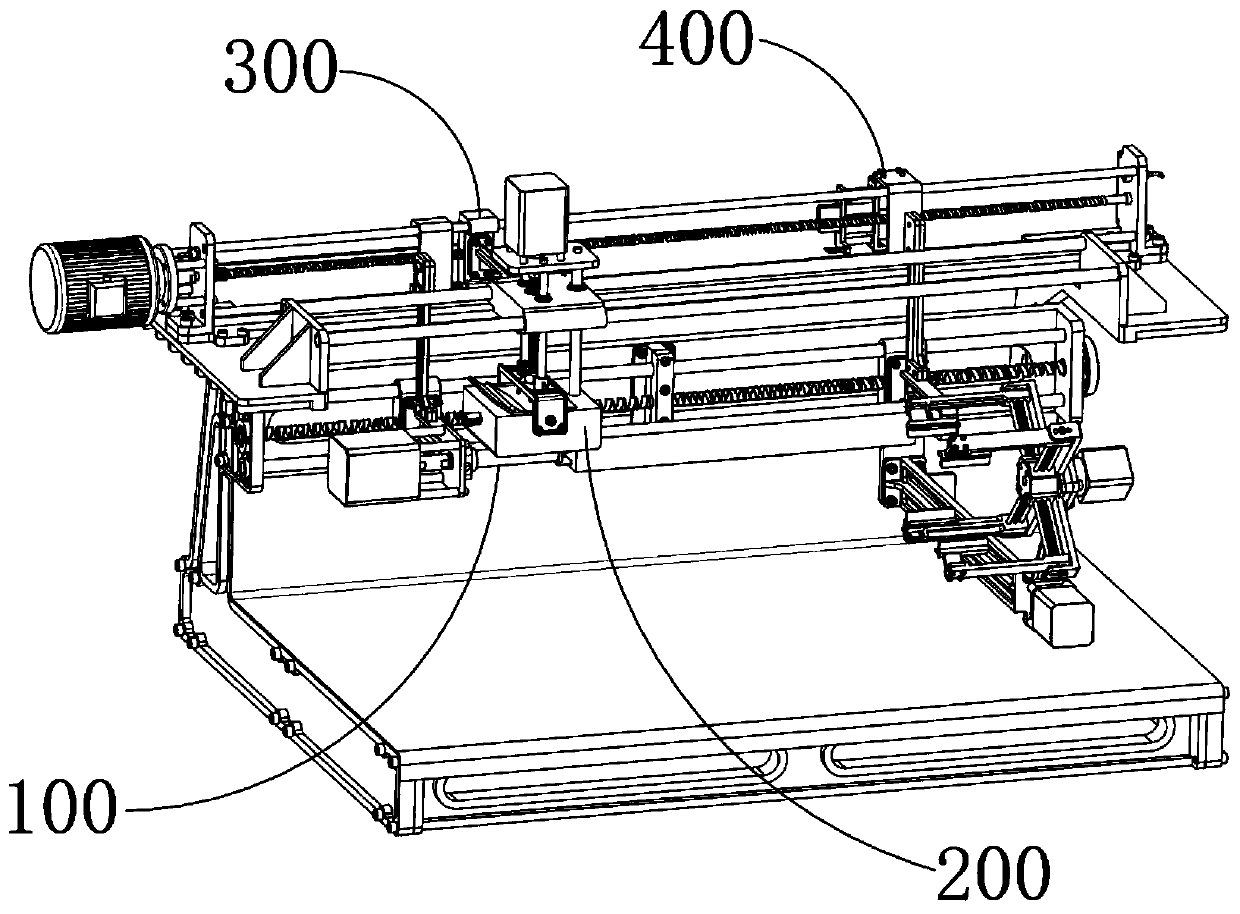

[0056] A numerical control machine tool for wood processing, which includes a clamping device 100 for clamping a long strip of wood workpiece, and a planing device 200 for reciprocating planing of the wood workpiece clamped by the clamping device 100 , the traveling driving device 300 for driving the planing device 200 to move in one direction along the planing direction, and the retraction control for releasing the driving of the planing device 200 by the traveling driving device 300 while pulling the planing device 200 to reset in a single reverse movement The device 400 , the planing device 200 is arranged above the clamping device 100 , the traveling driving device 300 is arranged on one side of the planing device 200 , and the retraction control device 400 is arranged on the traveling driving device 300 .

[0057] The process for the user to plan the plane of the wood workpiece is to clamp the wood workpiece on the clamping device 100 for fixing, and place the side to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com