Forming method and special device for complex surface composite material structural part

A technology of composite materials and special devices, applied in the field of process equipment, can solve problems such as overweight products, difficult molding, difficult assembly, etc., and achieve the effect of ensuring product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

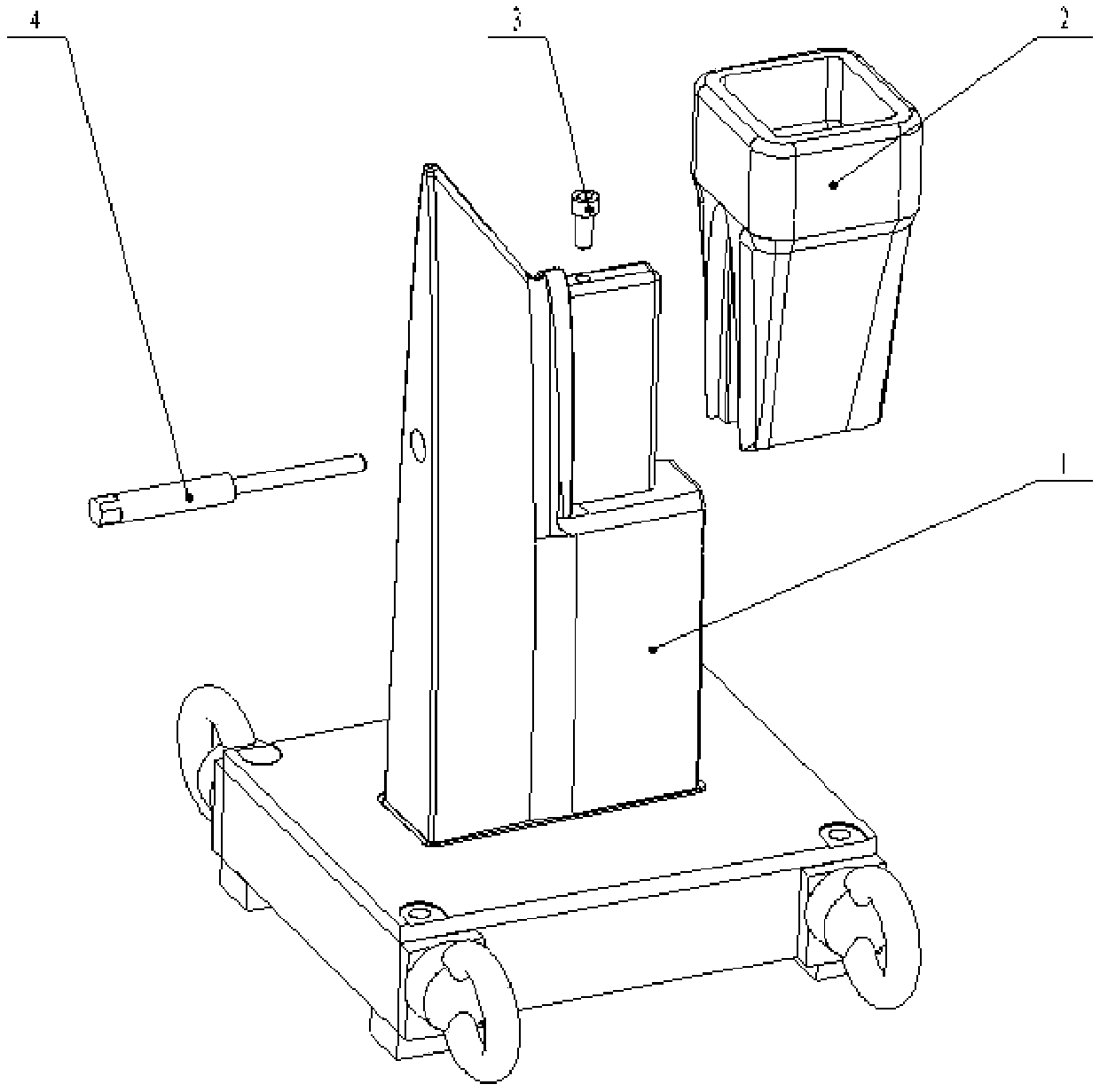

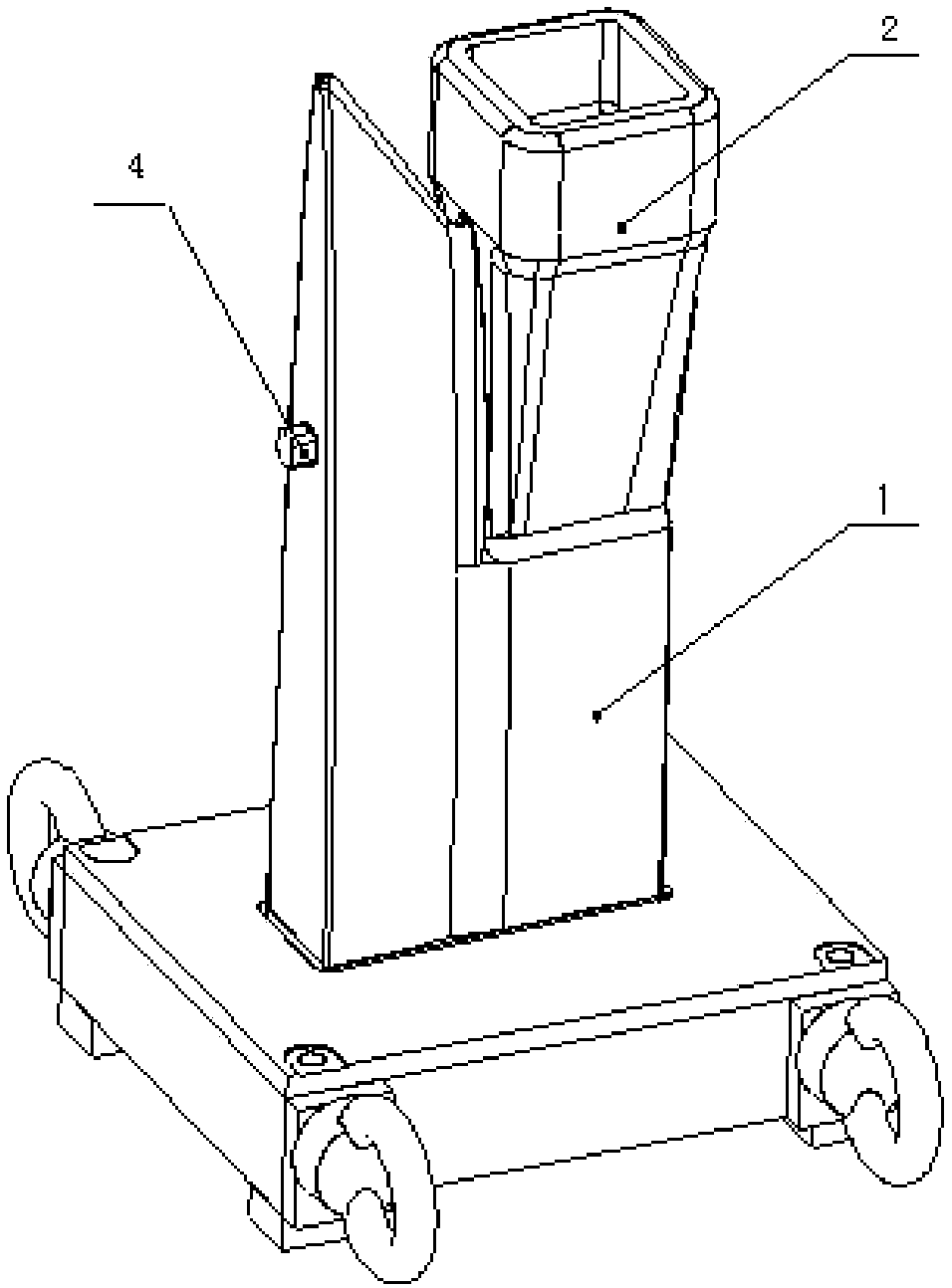

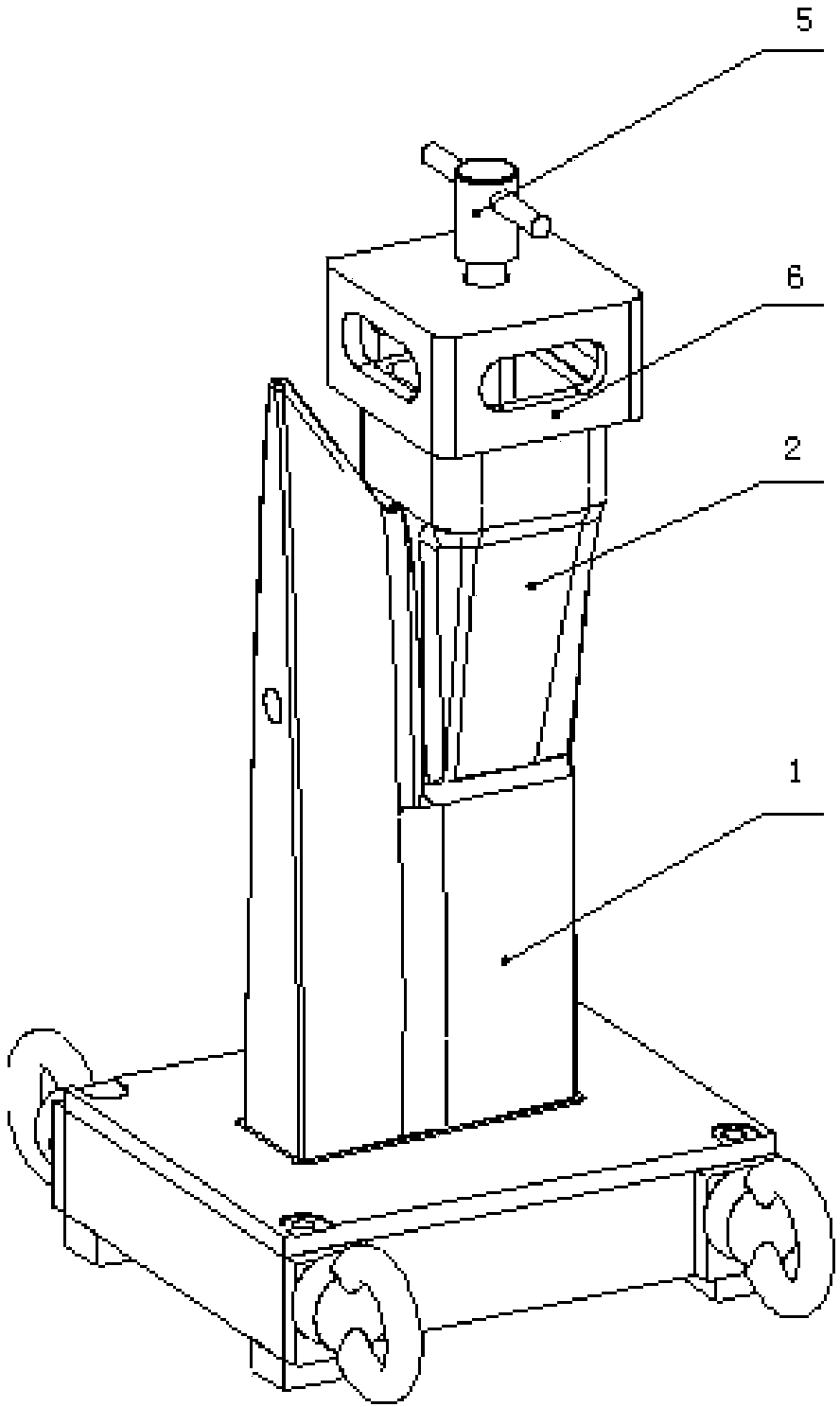

[0032] This structure is applied in the molding process of a certain type of vertical tail transmitting radome. The invention aims to solve the problem of difficulty in forming and demolding composite material structural parts with bidirectional underdrawing angles. The protection point of the present invention mainly lies in the formation and release of the two-way inverted angle composite material structural parts composed of the base 1, the parting body 2, the top pressing screw 3, the side tensioning screw 4, the demoulding screw 5, and the stop block 6. Modeling methods and special devices.

[0033] Below in conjunction with accompanying drawing this patent is described in detail:

[0034] A method for forming a composite material structural part with a complex profile. The specific steps of using the above-mentioned special device for forming a composite material structural part with a complex profile are as follows:

[0035] Step 1: Assemble the positioning boss of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com