High pressure sealing device for multi-measuring point square model

A high-pressure sealing, multi-measuring point technology, used in the extraction of undisturbed core devices, measurement, earthwork drilling and other directions, can solve the problems of non-reusable, long molding cycle, short molding cycle, etc. The effect of reducing operational requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

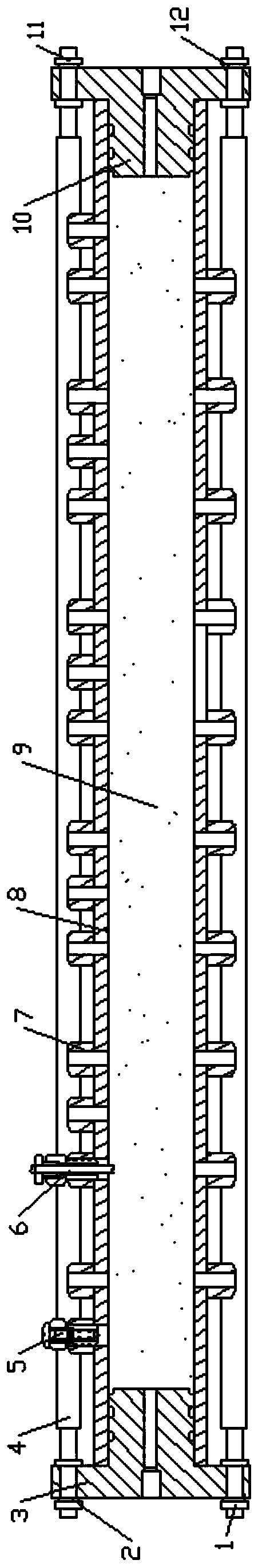

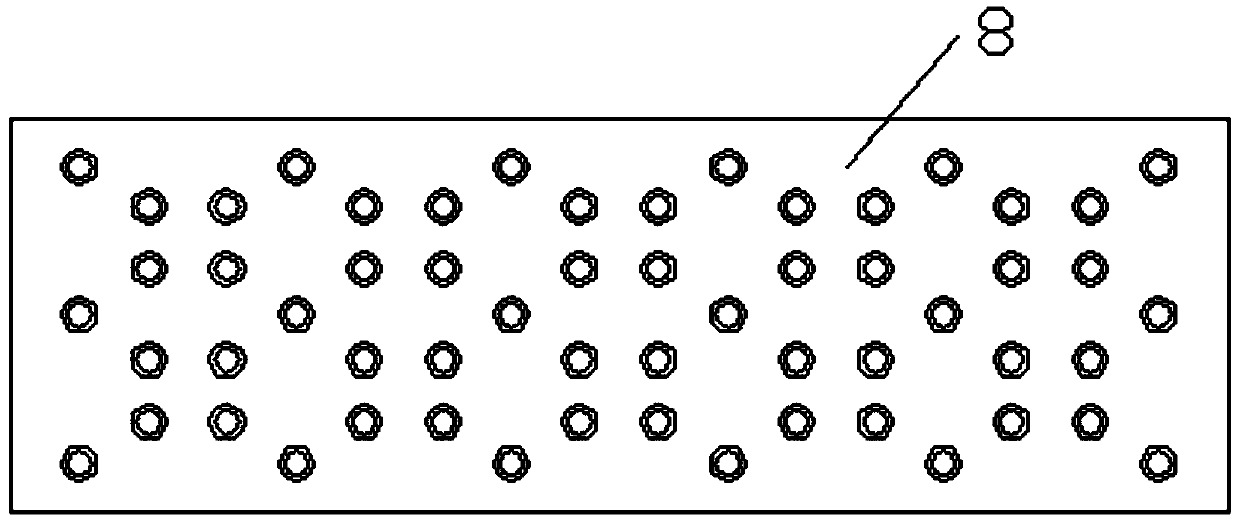

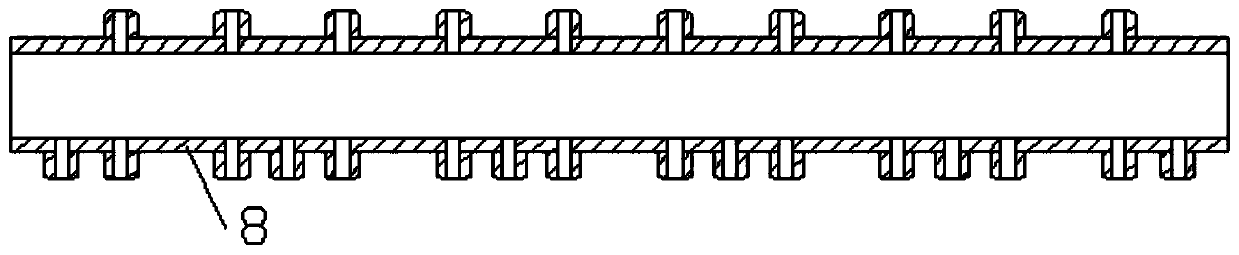

[0026] see Figure 1-10 , a high-pressure sealing device for a square model with multiple measuring points, including a square model body 9; the square model body 9 is placed in a rubber sleeve 8; Reliable, the dead corner is processed by arc linking process, the shape is square, and its inner cavity is set as square, and there are hollow cylindrical holes protruding outwards on it. The design and production process of the rubber sleeve 8 are industry-leading It is the first in China, the hollow cylinder is convenient for the insertion of resistance and pressure probes, and the square model body 9 is tightly hugged, and the left and right sealing plugs 3 and 10 are respectively installed at the left and right ends; the left sealing plug 3 There are trapezoidal concave-convex steps at the connecting parts of the right sealing plug 10 and the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com