A micro-flow high-precision light-weight miniaturized pressure regulator valve

A high-precision, micro-flow technology, used in valve devices, safety valves, balance valves, etc., can solve the problems of unguaranteed reliability and accuracy, poor compatibility of working medium, large flow, etc., and achieve easy assembly of the whole machine. , to achieve the effect of light weight miniaturization and strong process realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

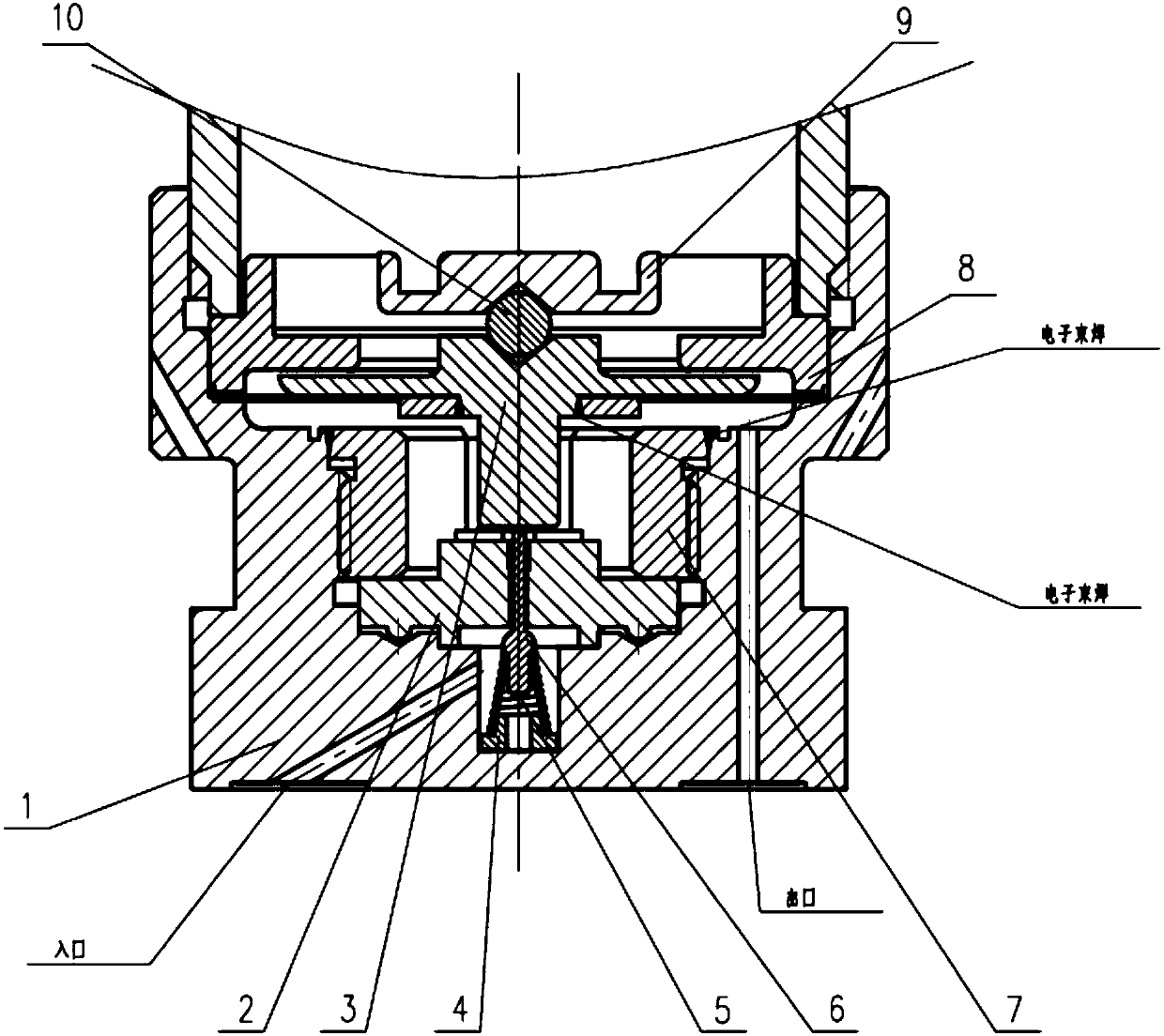

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the present invention includes a valve body 1, a valve seat 2, a diaphragm assembly 3, a spring seat 4, a spring 5, a valve core 6, a compression device 7, a compression ring 8, a main spring seat 9, and an adjustment ball 10;

[0027] The upper end of the diaphragm assembly 3 has a groove; the main spring seat 9 has a groove matching the groove of the diaphragm assembly 3;

[0028] The valve seat 2 is a combination of metal and non-metallic F4. During processing, a valve seat blank is processed first, and then the non-metallic F4 is placed in the corresponding structure through a hot-pressing process, and finally processed and formed, that is, the non-metallic F4 is processed by hot-pressing. To realize the sealing of parts; metal materials are usually titanium alloy, aluminum alloy, stainless steel, etc., and non-metal materials are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com