A Sealing Structure of Multi-measuring Point Specimen in True Triaxial Test

A technology with a sealing structure and multiple measuring points, which is used in the sealing of engines, preparation of test samples, mechanical equipment, etc., can solve the problems of non-reuse, difficult disassembly, long molding cycle, etc., and achieves reduced preparation work and convenient installation. , The sealing effect is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

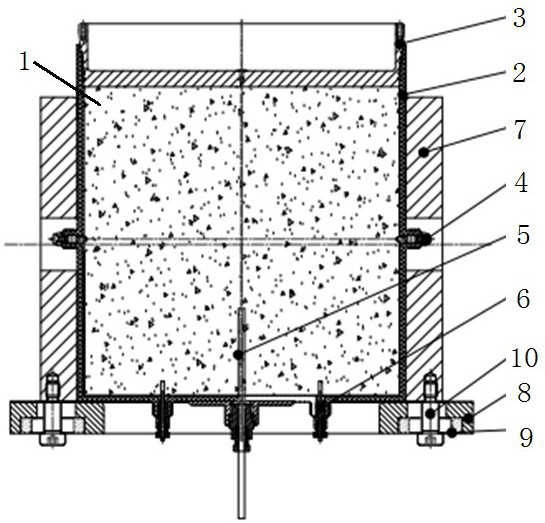

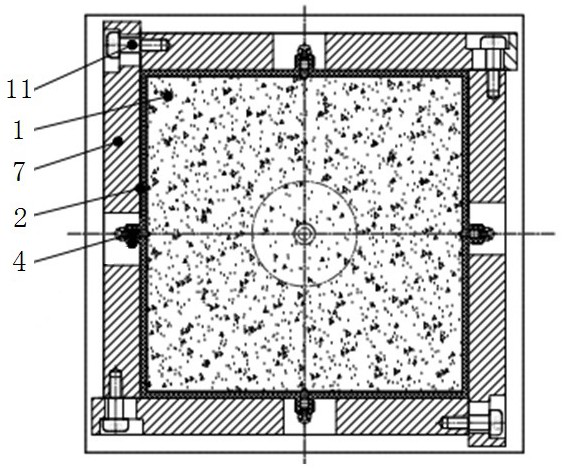

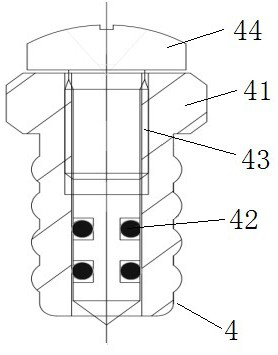

[0022] see figure 1 and figure 2 , the sealing structure of the multi-measuring-point sample of the true triaxial test is shown, including the sealing rubber sleeve 2 used to wrap the sample 1, and the sealing rubber sleeve 2 is arranged with four loading plates 7 in the front, rear, left, and right directions. Two plates 7 are connected by second bolts 11 , and the loading plate 7 and the bottom plate 8 encircle to form a loading cavity for placing the sealing rubber sleeve 2 . The bottom side of the base plate 8 is provided with a chute, and a slide block 9 is arranged in the chute, and the slide block 9 is fixedly connected with the loading plate 7 by using the first bolt 10, so that the loading plate 7 can slide along the base plate 8, and then the load plate 7 can slide according to the test needs. Adjust the position of the loading chamber for better true tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com