Reversing valve for plastic melt

A reversing valve and melt technology, which is applied in the field of reversing valves for plastic melts, can solve the problems of inability to discharge, blockage of pipes, and confusion, and achieves the effects of convenient use, easy cleaning and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

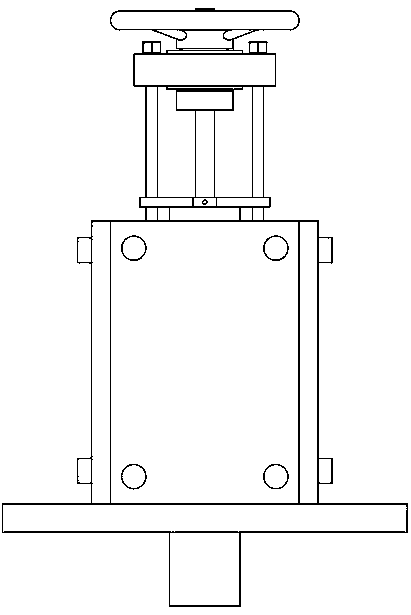

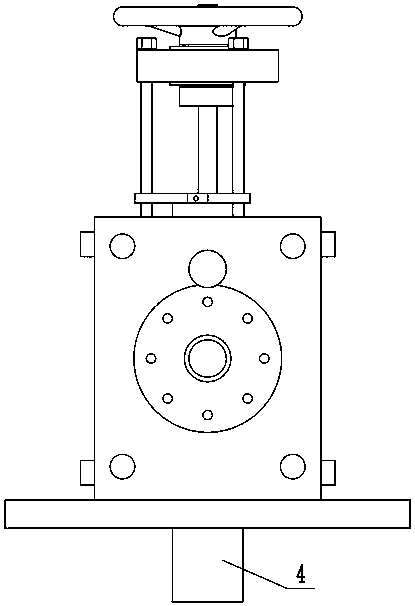

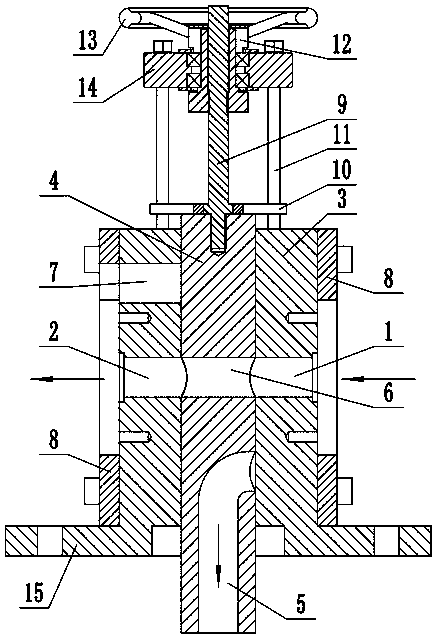

[0024] Referring to the accompanying drawings, the reversing valve for plastic melt includes a valve body 3 with a feed hole 1 on the right and a discharge hole 2 on the left, wherein the feed hole 1 and the discharge hole 2 are circular Shaped hole and coaxial arrangement, in addition, the middle part of valve body 3 is also provided with the valve cavity that penetrates valve body up and down and communicates with feed hole 1 and discharge hole 2, and this valve cavity is also preferably round hole shape; In addition, valve cavity The middle slide is equipped with a spool 4 that can slide up and down. Of course, the spool 4 is also in the shape of a vertical column; in addition, the top of the valve body 3 is equipped with a driving device that can drive the spool 4 to move up and down. The device can be driven manually or electrically, such as Figure 1-Figure 6 As shown, the preferred driving device is a manual driving mode. Therefore, the driving device includes a valve r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com