Aluminum alloy battery pack for new energy vehicle

A new energy vehicle, aluminum alloy technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as copper bar breakage, battery module loosening, affecting the use of battery packs, etc., to extend service life, reduce Temperature change, the effect of increasing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

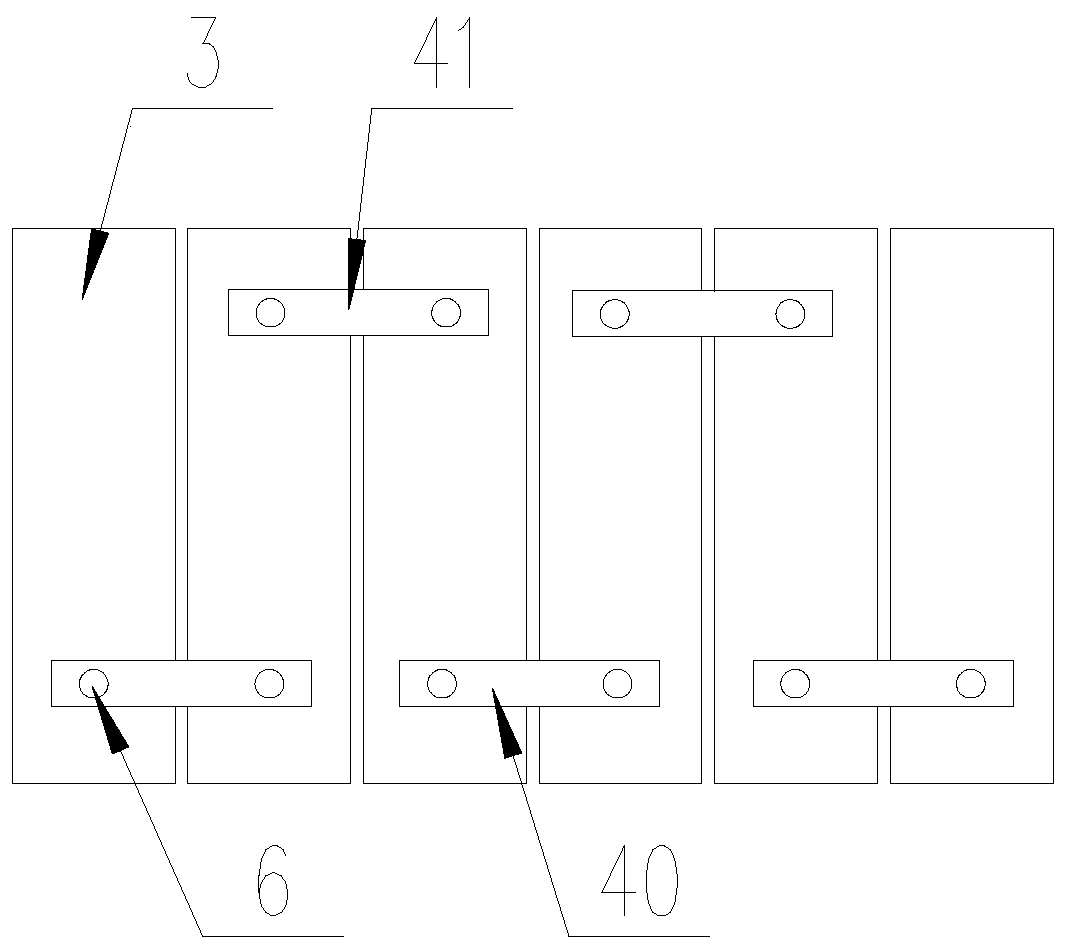

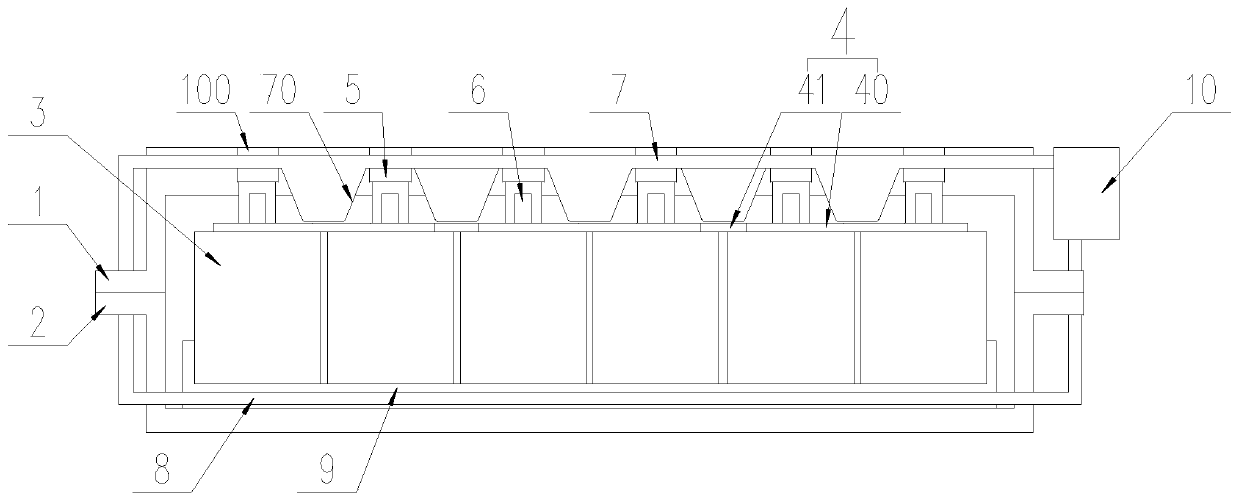

[0040] Such as figure 1 and figure 2 As shown, an aluminum alloy battery pack for new energy vehicles includes an upper case 1, a lower case 2, and a plurality of battery modules 3 located between the upper case 1 and the lower case 2, the battery modules 3 are connected through the conductive copper bar 4, the screw 6 passes through the conductive copper bar 4 and is connected to the upper end of the battery module 3, the upper casing 1 is provided with a vertically downward connecting pipe 5, and the connection The tube 5 is provided with an internal thread and is connected to the screw 6 .

[0041] Thread the upper case 1 to the screw 6 that connects the conductive copper bar 4 and the battery module 3, so that the upper case 1 and the battery module 3 are connected as a whole. When the distance between the battery module 3 occurs due to temperature changes or vibration When changing, the connection point between the upper casing 1 and the screw rod 6 is fixed, and will ...

Embodiment 2

[0050] Such as figure 1 , 2 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the battery protection frame 9 is embedded with a heat dissipation pipe 2 8, and the heat dissipation pipe 2 8 communicates with the heat dissipation pipe 7 through a vertical heat dissipation pipe 71. The bottom of the battery protection frame 9 is provided with a cooling pipe 2 8, which can further quickly dissipate the heat generated by the operation of the battery module 3, and the embedded method can prevent the uneven bottom of the battery protection frame 9 from causing the battery module 3 to shake.

[0051] The heat dissipation pipe 2 8 passes through the lower casing 2 and is embedded in the battery protection frame 9 .

[0052] The two radiating pipes 8 are multiple and arranged in parallel, the multiple radiating pipes 7 dissipate heat at the same time, and the heat dissipation area is large.

[0053] The heat dissipation pipe 7 and the heat dissip...

Embodiment 3

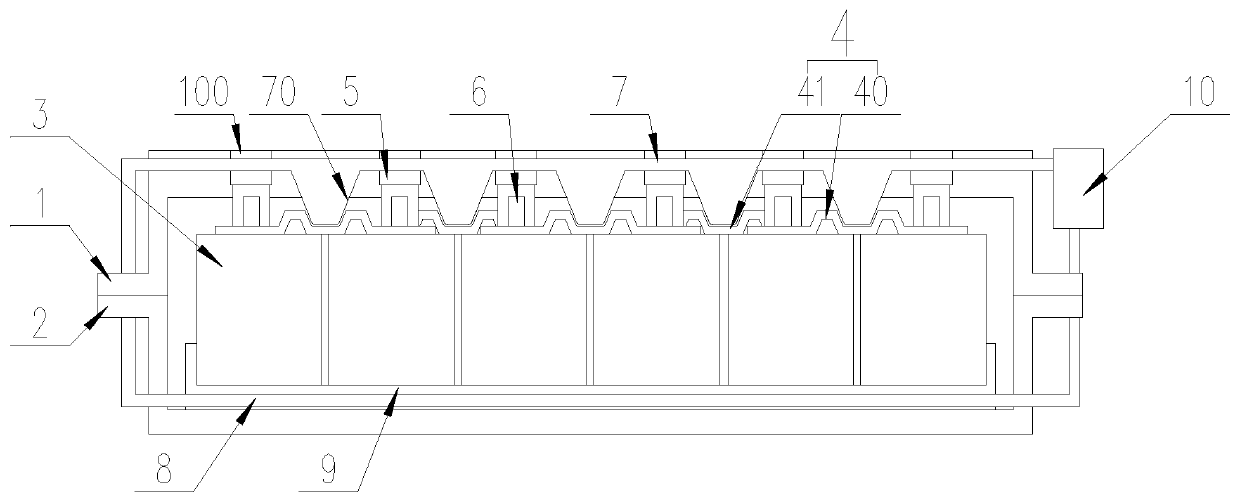

[0058] Such as image 3 As shown, the difference between this embodiment and Embodiment 2 is that the conductive copper bar 4 includes connection parts at both ends and a bending part in the middle, and the screw rod 6 connects the battery module 3 and the connection part.

[0059] The curved portion includes an upper convex portion and a lower concave portion arranged at intervals, and the conductive copper bar 4 with this structure has good tensile and compressive properties.

[0060] The upper casing 1 is provided with a second lower recess matching the lower recess.

[0061] The surface of the conductive copper bar 4 is provided with an insulating and heat-conducting layer, and the bent portion 70 is in contact with the second concave portion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com