Paddy field soil turning and soil preparing integrated machine applicable to minimal tillage planting mode

A paddy field, integrated machine technology, applied in agricultural machinery and implements, shovels, plows and other directions, can solve the problems of uneven soil, strenuous, unfixable structure of scattered soil, etc., to improve the dispersion effect, improve efficiency and dispersion effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

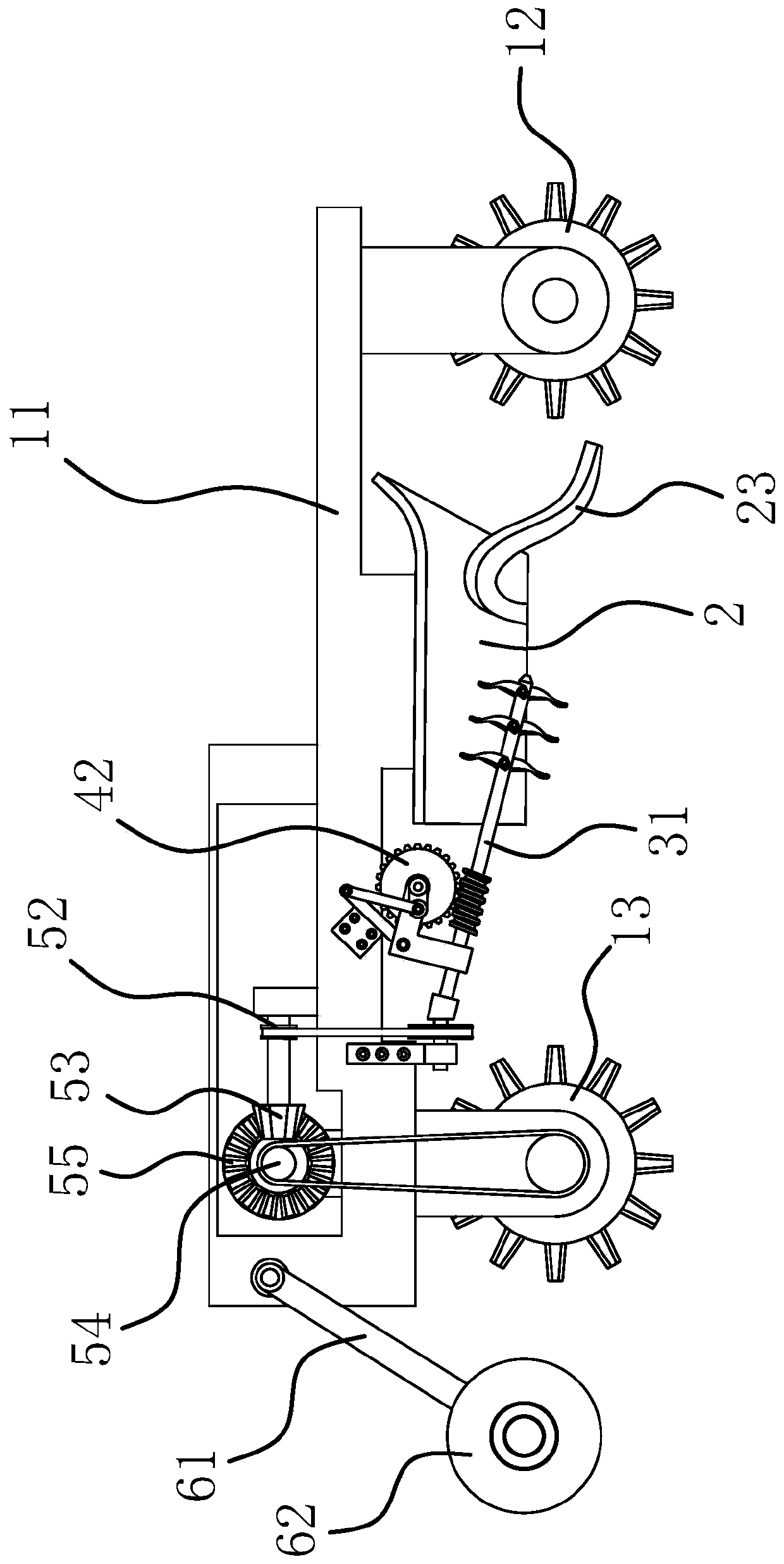

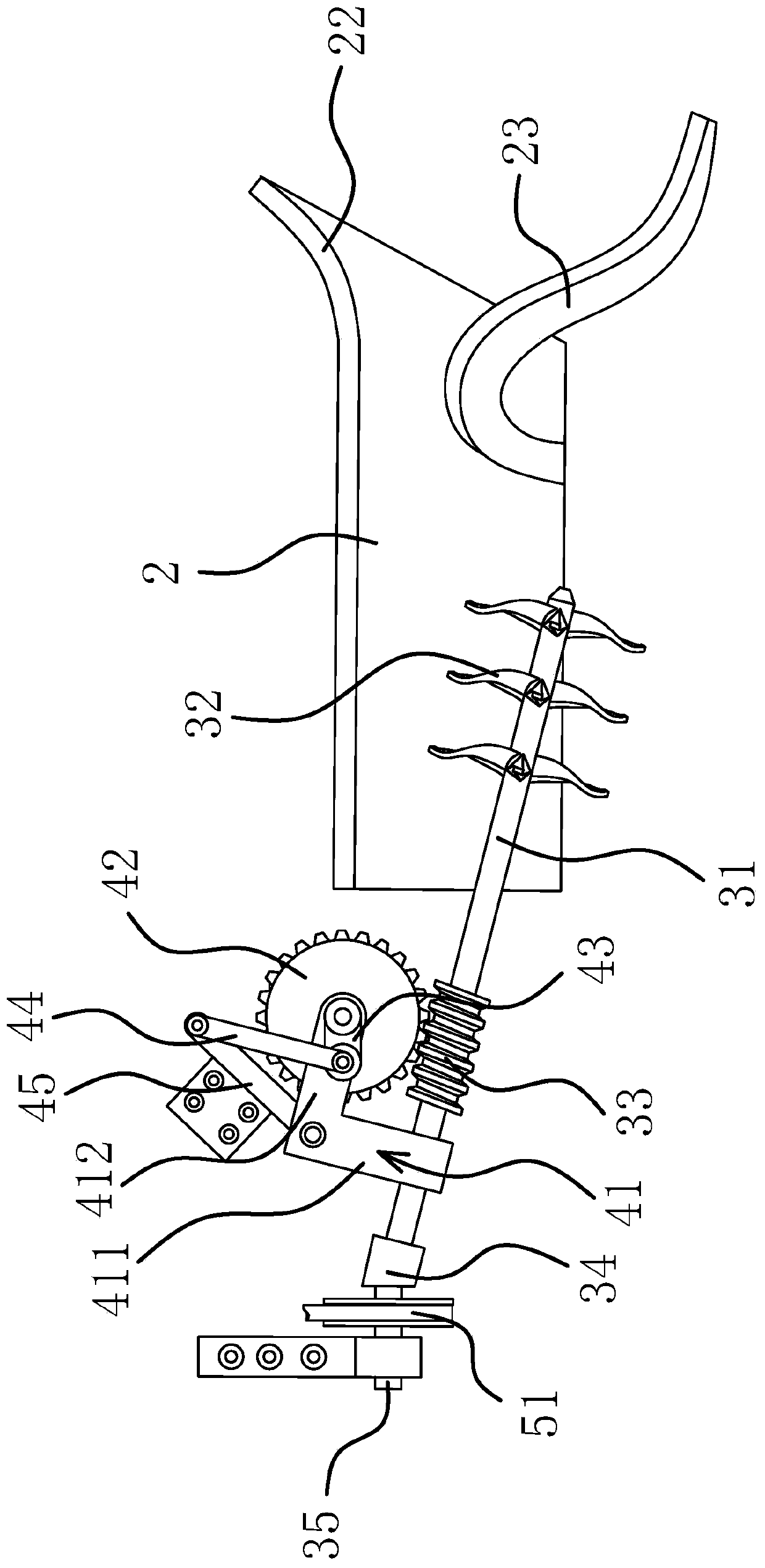

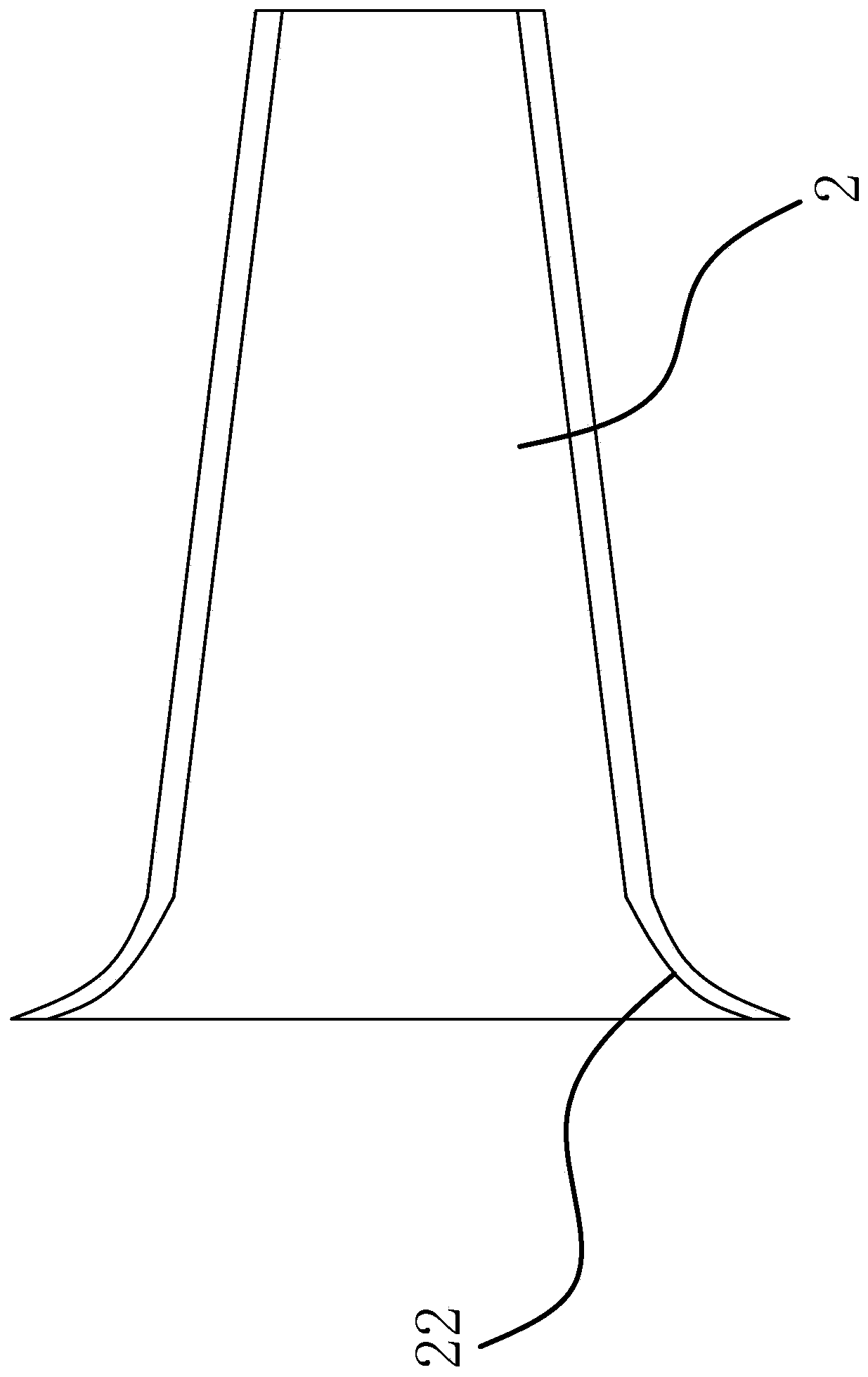

[0036] Such as figure 1 and figure 2 As shown, the all-in-one machine for tilling and preparing soil includes a frame 11, a steering wheel 12 arranged at the front end of the frame 11, a driving wheel 13 arranged at the rear end of the frame 11, and a power source for driving the driving wheel 13 to rotate, located at the steering wheel 12 On the frame 11 between the road wheels 13, several plowing units of spacing distribution are arranged, and the plowing unit includes an enclosure cover 2, a plowing cutter 23 and a dispersion shaft 31, and the protective cover is fixed on the frame 11, and the plowing cutter 23 is fixed In the enclosure 2, the plowing cutter 23 partly stretches out from the front end of the enclosure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap