Waste treatment equipment for improving ecological environment

A technology of ecological environment and processing equipment, which is applied in the direction of grain processing, etc., can solve the problems that waste is easy to stick to the crushing components, increase the work intensity of staff, and waste is easy to splash outwards, etc., to achieve convenient storage and automatic Push, easy to clean, to ensure the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

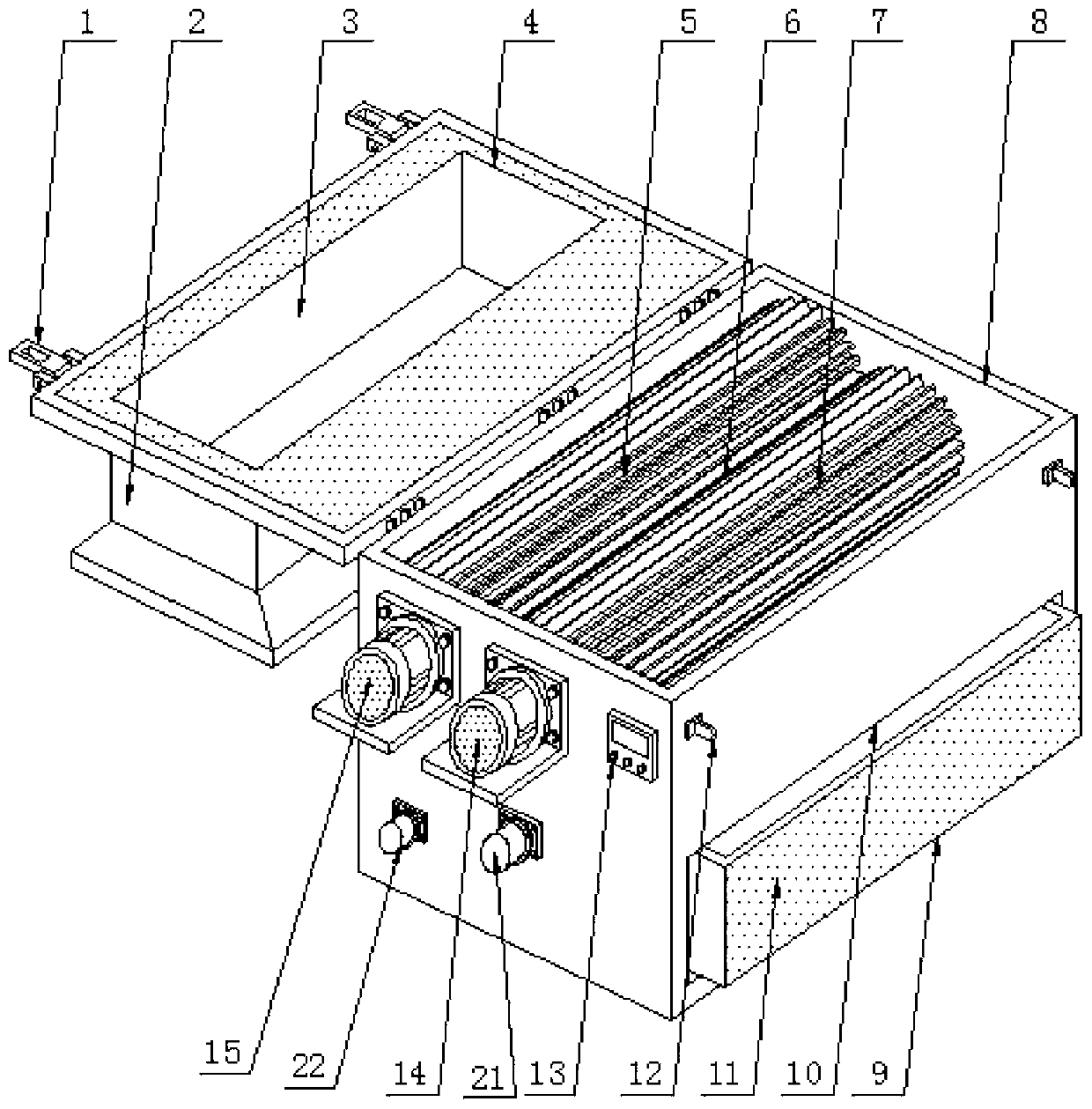

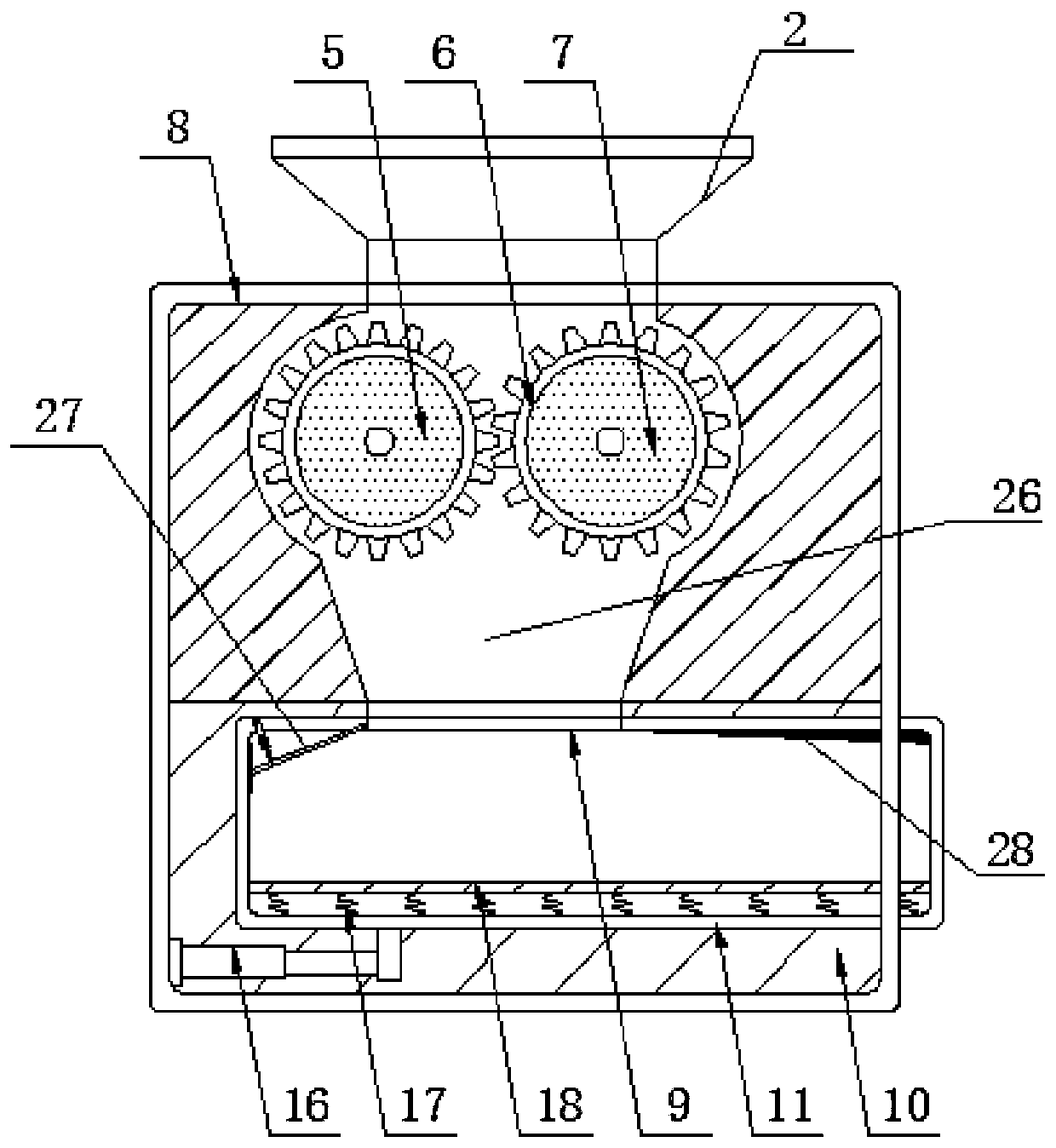

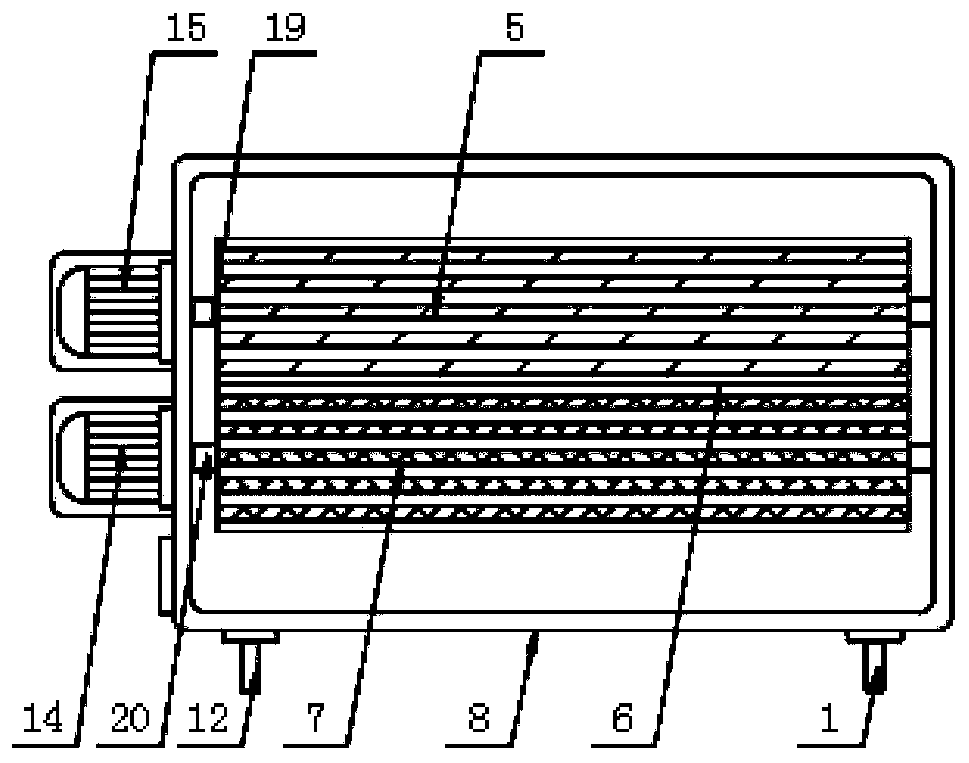

[0031] see Figure 1~5 , in an embodiment of the present invention, a waste treatment device for improving the ecological environment, including a support frame 24, a treatment box 8, a turning assembly, a protection assembly 4, a crushing assembly 6, a waste storage box 11 and a pushing assembly 9, which characterized in that,

[0032] The left and right ends of the processing box 8 are supported on the support frame 24 by using the turning shaft to turn 180°, and the turning movement of the handling box 8 is driven by the turning assembly;

[0033] The vertical sides of the treatment box 8 are respectively provided with a protective assembly 4 and a waste storage box 11;

[0034] The crushing assembly 6 is arranged between the protection assembly 4 and the waste storage box 11 in the processing box 8; the end of the protection assembly 4 is provided with a feeding port 2, and the protection assembly 4 can be Disconnected connection to the processing box 8;

[0035] The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com