Groove forming tool for prefabricated member and forming die assembly

A technology of prefabricated components and forming tooling, which is applied in the direction of manufacturing tools and ceramic forming machines, can solve the problems of cumbersome operation, complex forming process, and low production efficiency, and achieve the effects of improving production efficiency, stable and reliable pre-embedding, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

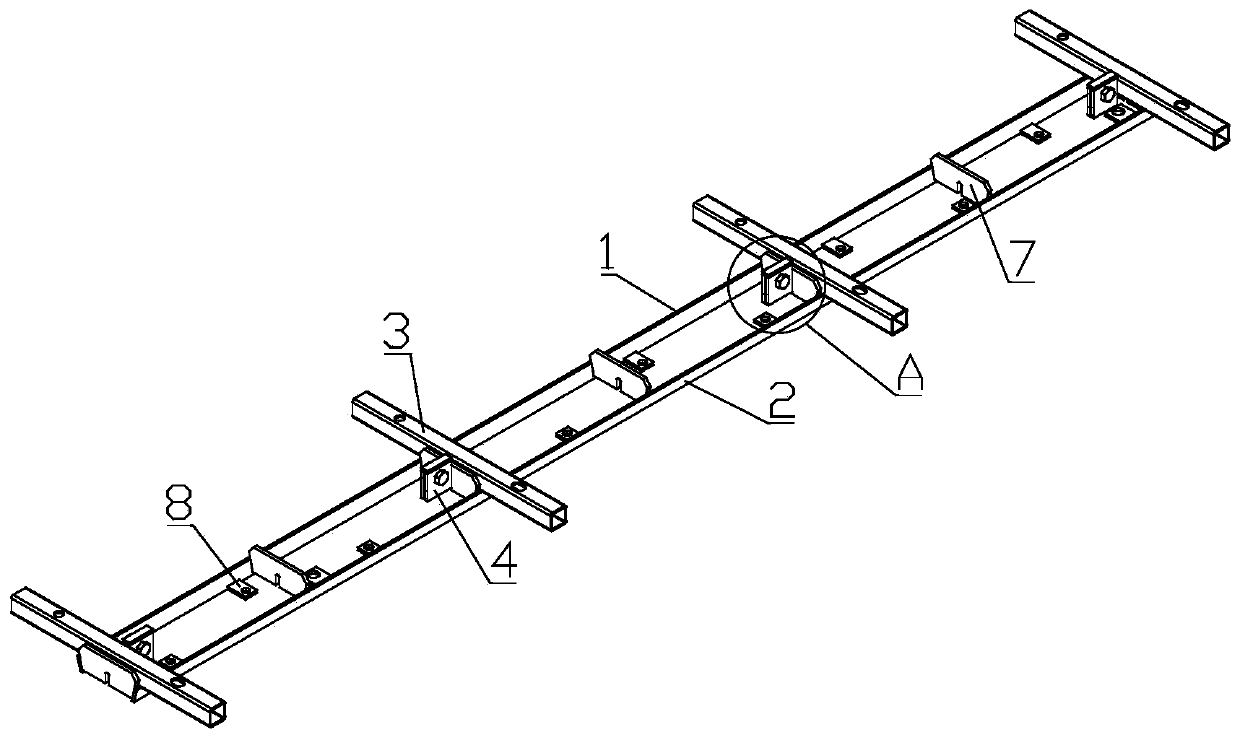

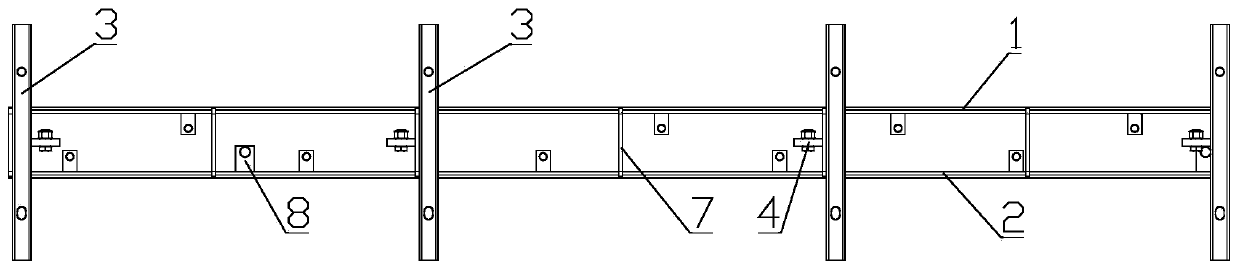

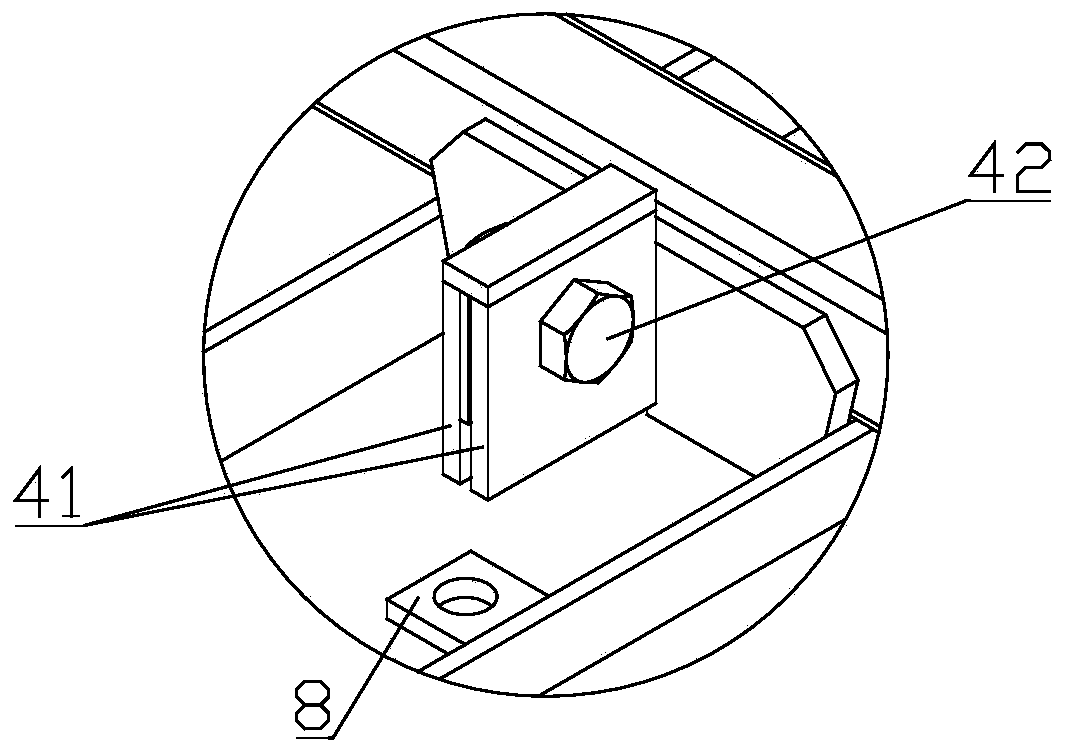

[0023] see Figure 1-3 , the groove forming tool for the prefabricated bay window is used to form the groove 5 on the end of the prefabricated bay window 6 , which includes a first plate 1 , a second plate 2 , a support 3 and a clamping device 4 .

[0024] The first plate 1 and the second plate 2 are arranged symmetrically with respect to the vertical plane. They can be parallel to each other or form a certain angle with each other. The shape of the groove 5 , the groove 5 extends along the extension direction of the first board 1 , and the cross section of the groove 5 can be a rectangle, a trapezoid or an inverted trapezoid.

[0025] The support member 3 is fixedly arranged above the first plate 1 and the second plate 2, the extension direction of the support member 3 is perpendicular to the extension direction of the first plate 1, and the length of the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap