Method for monitoring gas flow development process in blast furnace material distribution period and predicting gas utilization rate

A technology of development process and gas flow, which is applied in the field of monitoring the development process of gas flow in blast furnace distribution cycle and predicting gas utilization rate, can solve the problems of difficult to track and identify relationship, difficult to determine, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the examples. The following description is only used to illustrate the technical solution of the present invention and not limit it.

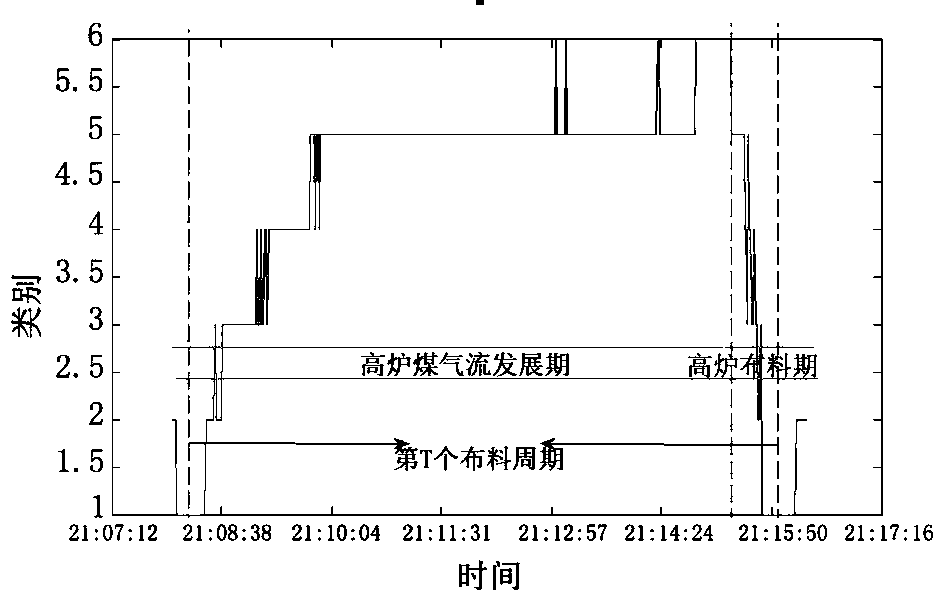

[0034] The present invention collects the blast furnace (2500m2) of a certain steel factory 3 ) from October to December 2013 to study the production data; provide a method for monitoring the gas flow development process of the blast furnace cloth distribution cycle and intelligently predicting the gas utilization rate; including the following steps: (1) data collection and processing; (2) ) Infrared image processing; (3) Image feature extraction; (4) Establishment of dynamic change model of gas flow distribution during cloth distribution period; (5) Feature extraction of gas flow center; (6) Position calibration of image and material surface; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com