Multifunctional floor tile automatic laying device

An automatic laying and multi-functional technology, applied in the field of construction equipment, can solve the problems of high work intensity, low work efficiency, and large workload of workers, and achieve the effect of reducing work intensity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

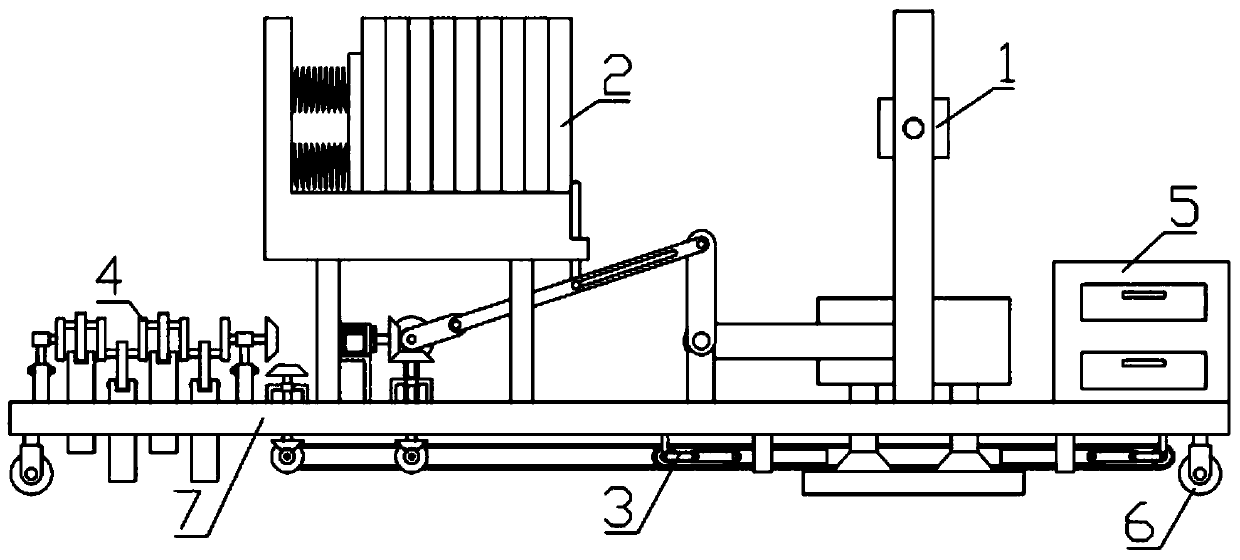

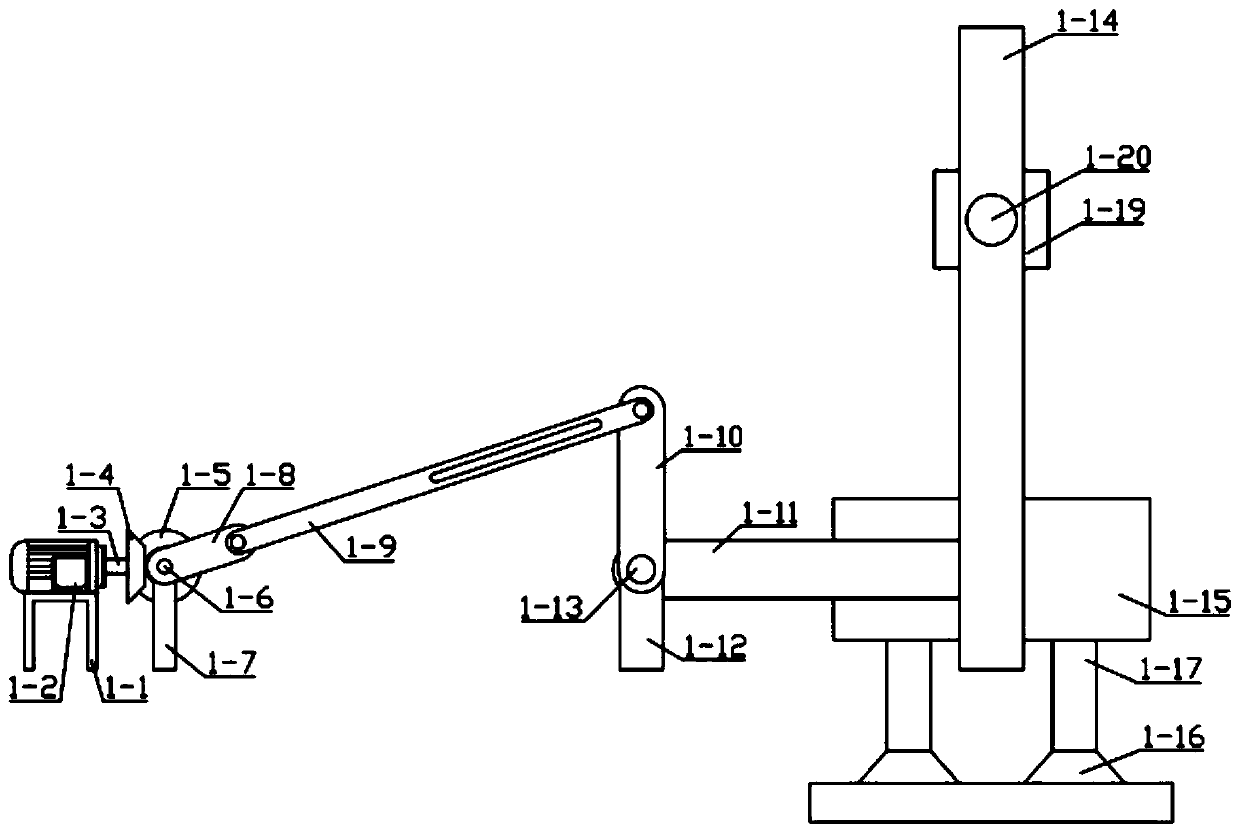

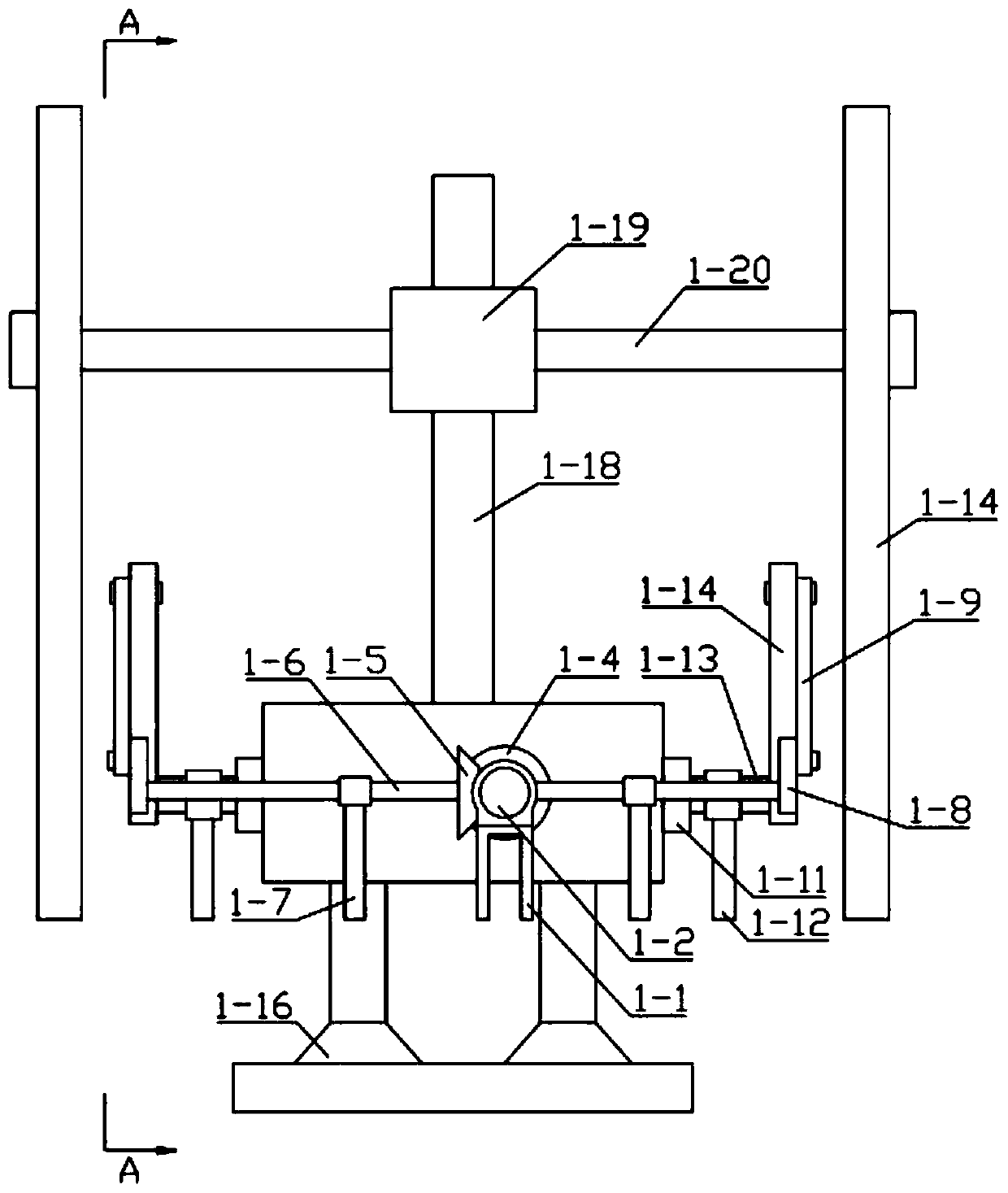

[0031] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 Describe this embodiment mode, the present invention relates to a kind of construction equipment, more specifically a kind of multifunctional floor tile automatic laying device, comprising floor tile laying mechanism 1, floor tile transportation mechanism 2, brick unloading mechanism 3, floor tile laying and beating mechanism 4, storage Box 5, roller 6, base 7, the device can automatically lay the floor tiles, the device can transport the floor tiles, provide for use, the device can unload the floor tiles, complete the laying of the floor tiles, the device can beat the floor tiles, make the floor tiles lay firmly, improve the work efficiency of workers, Reduce work intensity.

[0032] The floor tile laying mechanism 1 includes a motor fixing frame 1-1, a motor 1-2,...

specific Embodiment approach 2

[0038] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 This embodiment will be described, and this embodiment will further describe Embodiment 1. The materials of the suction disc 1-16 and the beating glue column 4-16 are the same, both of which are rubber.

[0039] How to use the device: The device can automatically lay floor tiles, motor shaft 1-3 drives bevel gear 1-4 to rotate, bevel gear 1 1-4 drives bevel gear 2 1-5 to rotate, bevel gear 2 1-5 drives connecting shaft 1 1-6 rotates, connecting shaft one 1-6 drives curved rod one 1-8 to rotate, curved rod one 1-8 drives curved rod two 1-9, curved rod two 1-9 drives curved rod three 1-10 to rotate, and curved rod two 1-9 drives curved rod three 1-10 to rotate, Rod three 1-10 drives connecting shaft two 1-13 to rotate, connecting shaft two 1-13 drives curved rod four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com