Double fan-shaped gear beam extended range pumping unit

A sector gear and pumping unit technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of low chain service life, low belt winding life, large reversing impact force, etc., and achieve reliable performance. The effect of good performance, less floor space and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

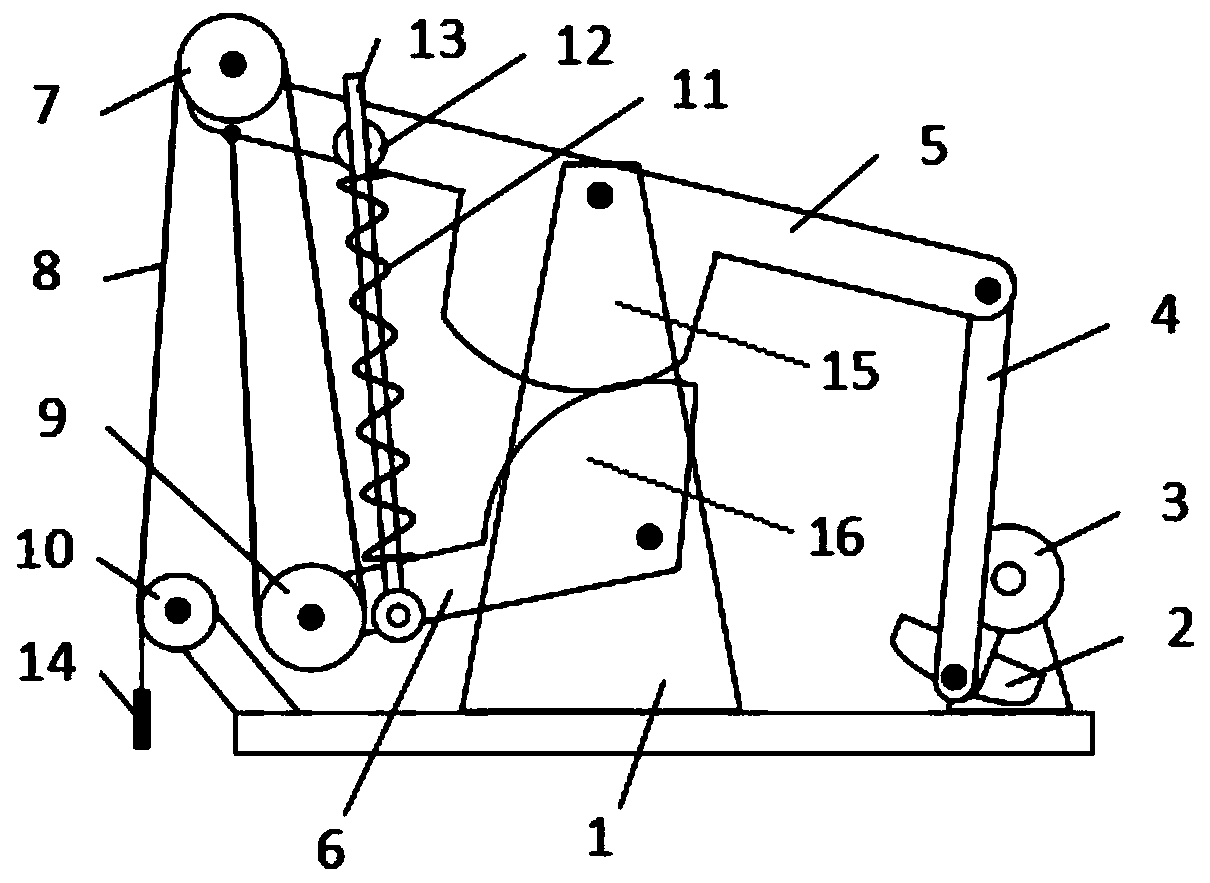

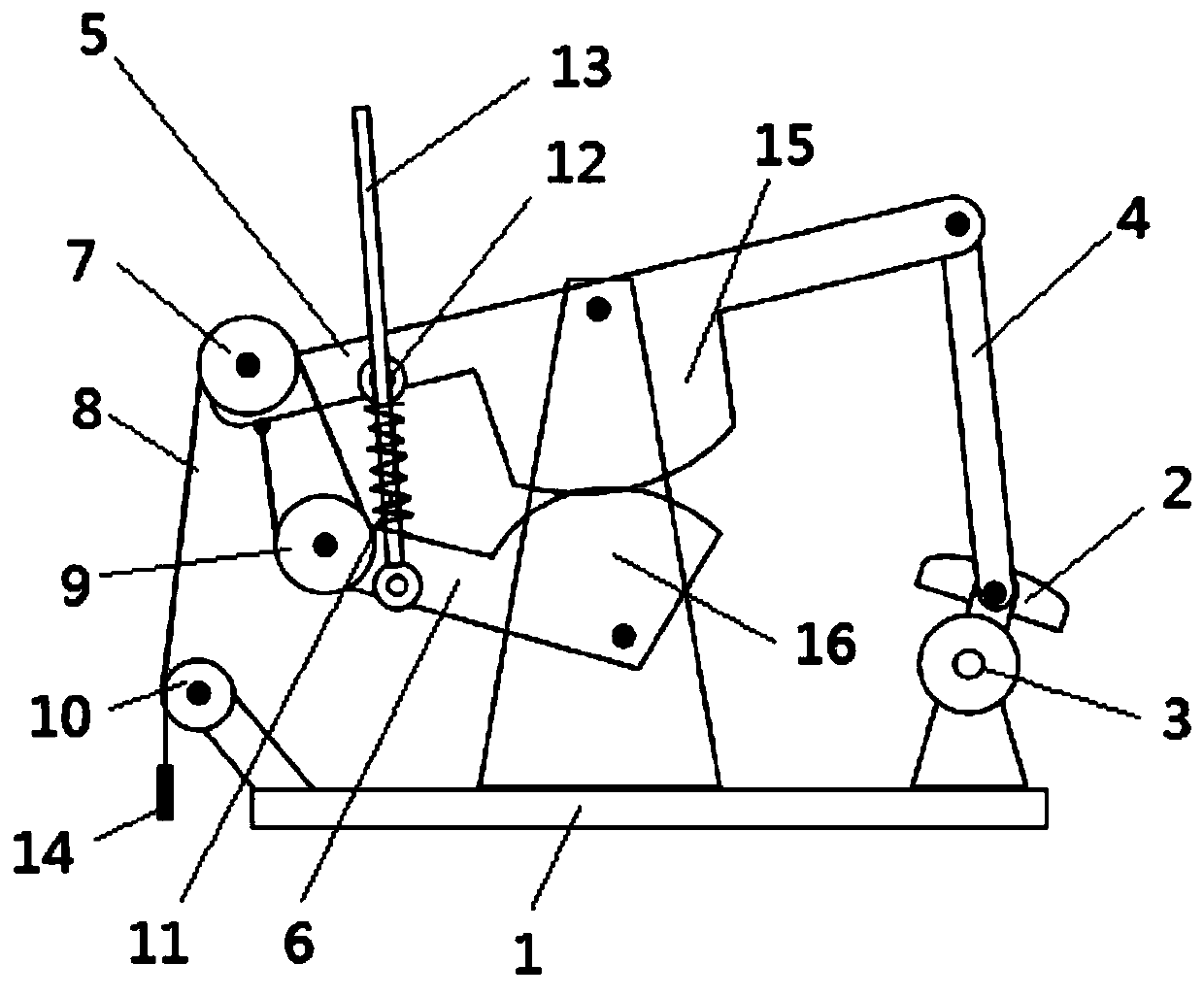

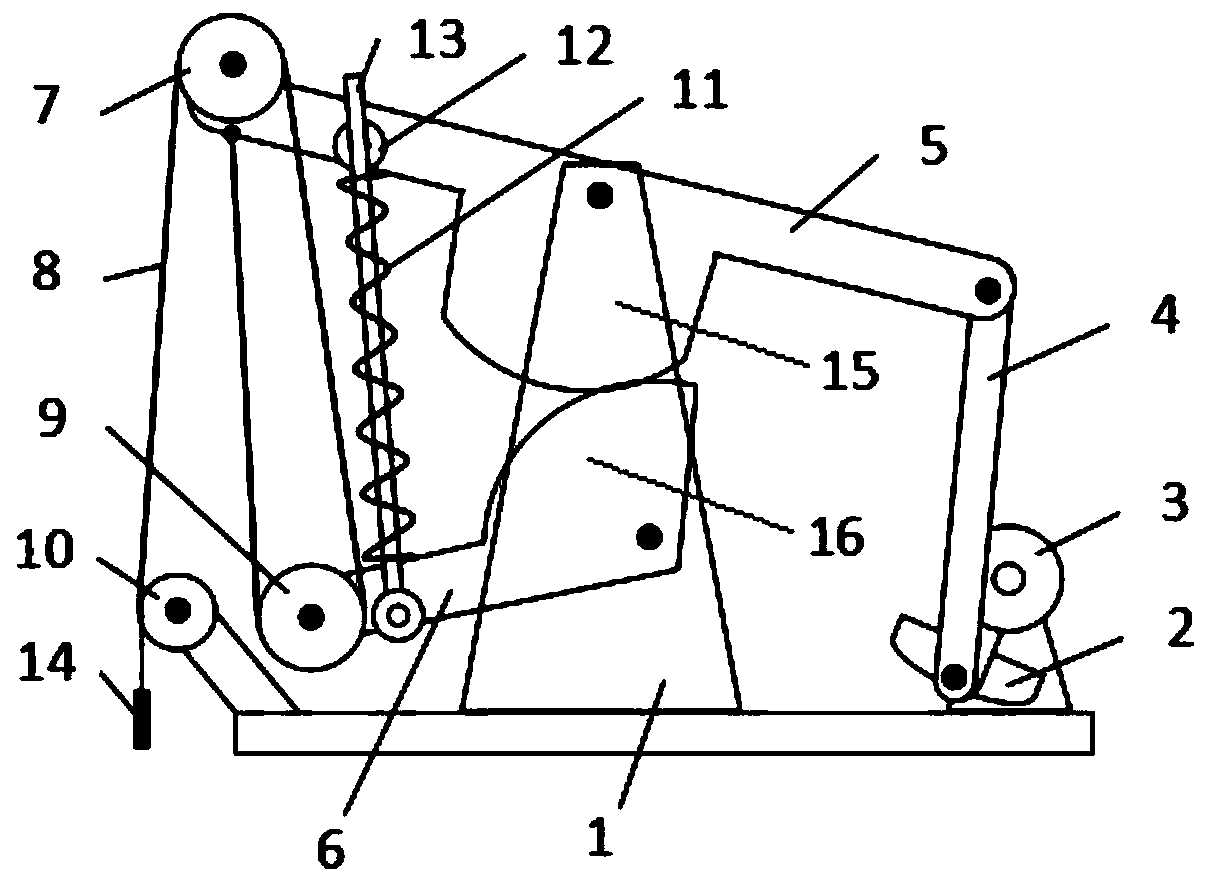

[0025] Such as Figure 1~2 As shown, this embodiment provides a double-sector gear beam extended-range oil pumping unit, including a base 1, a motor reducer, a crank 3, a connecting rod 4, an upper beam 5, a lower beam 6, an upper pulley 7, a steel wire belt 8, The lower pulley 9, the guide roller 10, the spring 11, the guide rod 13, the straight pin 12 and the sucker rod 14, the upper beam 5 is provided with the first sector gear 15 and the first gear center through hole, and the lower beam 6 is provided with The second sector gear 16 and the center through hole of the second gear, the first gear center through hole is rotationally connected with the upper middle of the base 1 through a pin shaft, the first sector gear 15 rotates around the axis where the first gear center through hole is located, The center through hole of the second gear rotates and connects with the middle bottom of the base 1 through the pin shaft, and the second sector gear 16 rotates around the axis where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com