Multifunctional high-pressure pump

A high-pressure pump, multi-functional technology, used in pumps, rotary piston pumps, rotary piston/oscillating piston pump combinations, etc., can solve the problems of low delivery pressure, low efficiency, poor sealing between vanes and cylinders, etc. , to achieve the effect of strong pressure, large flow and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

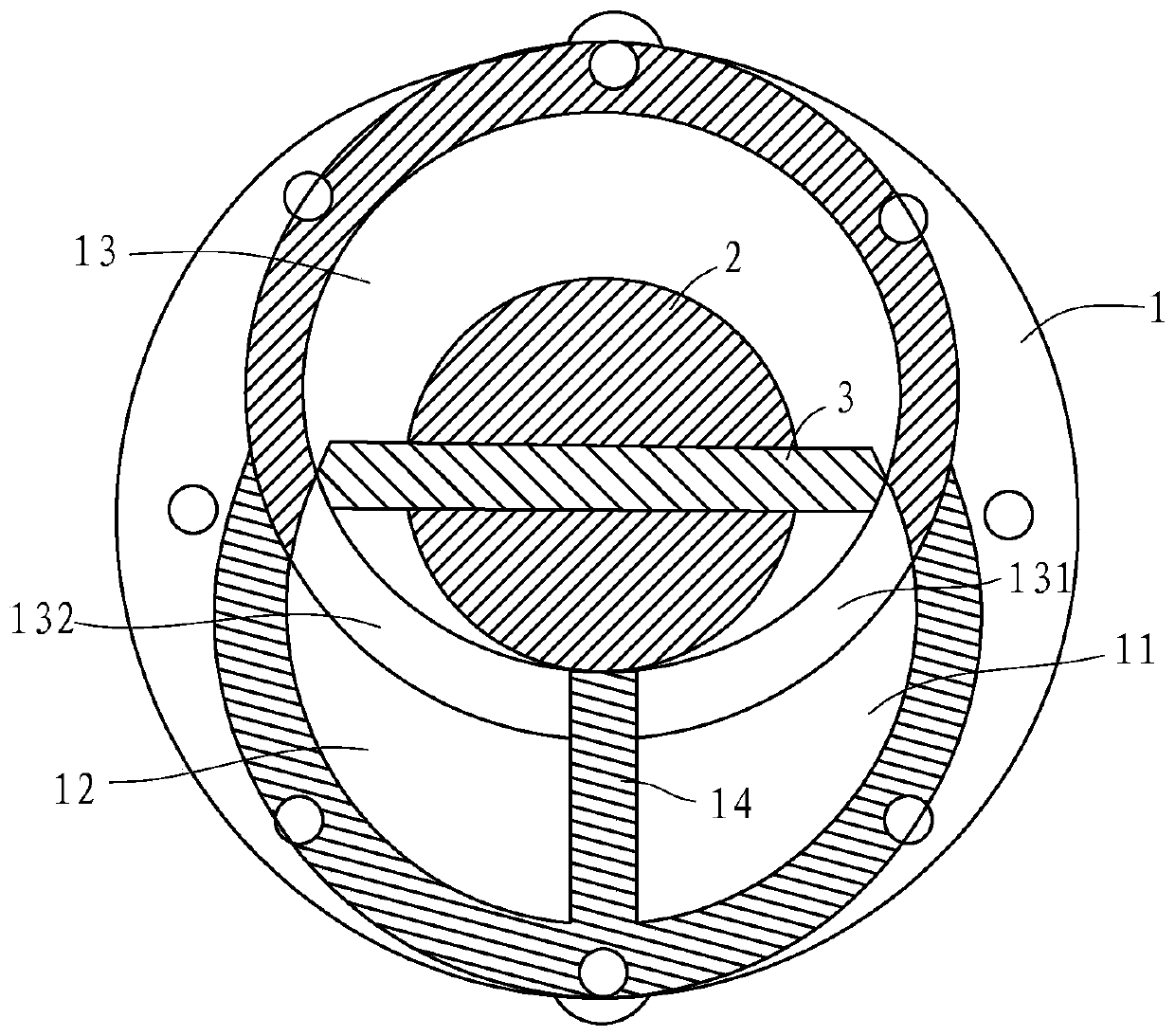

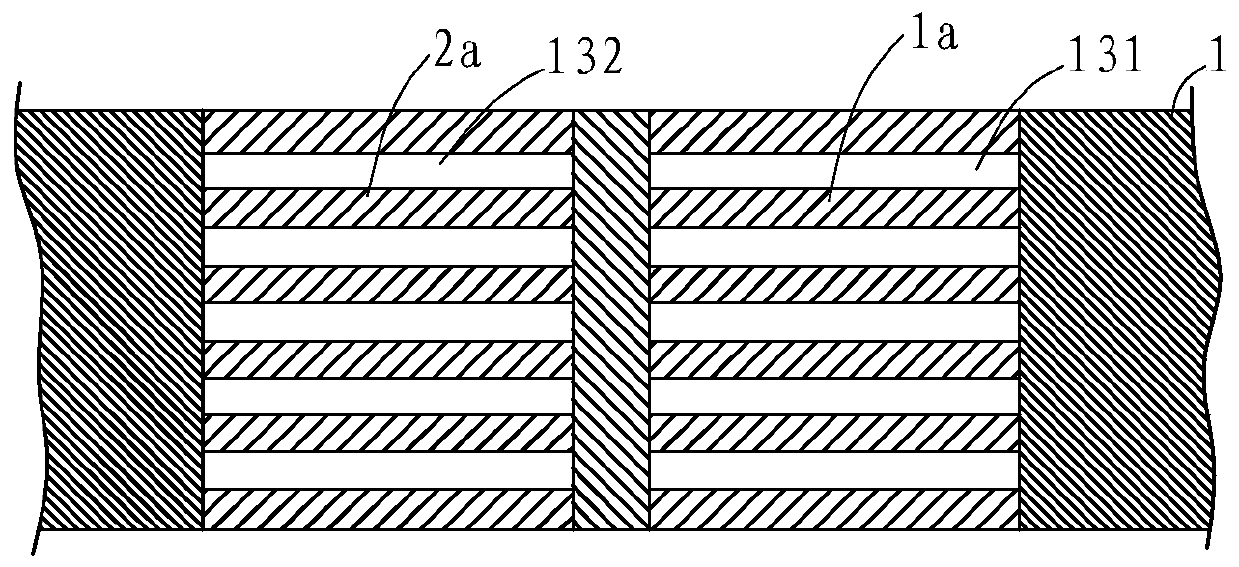

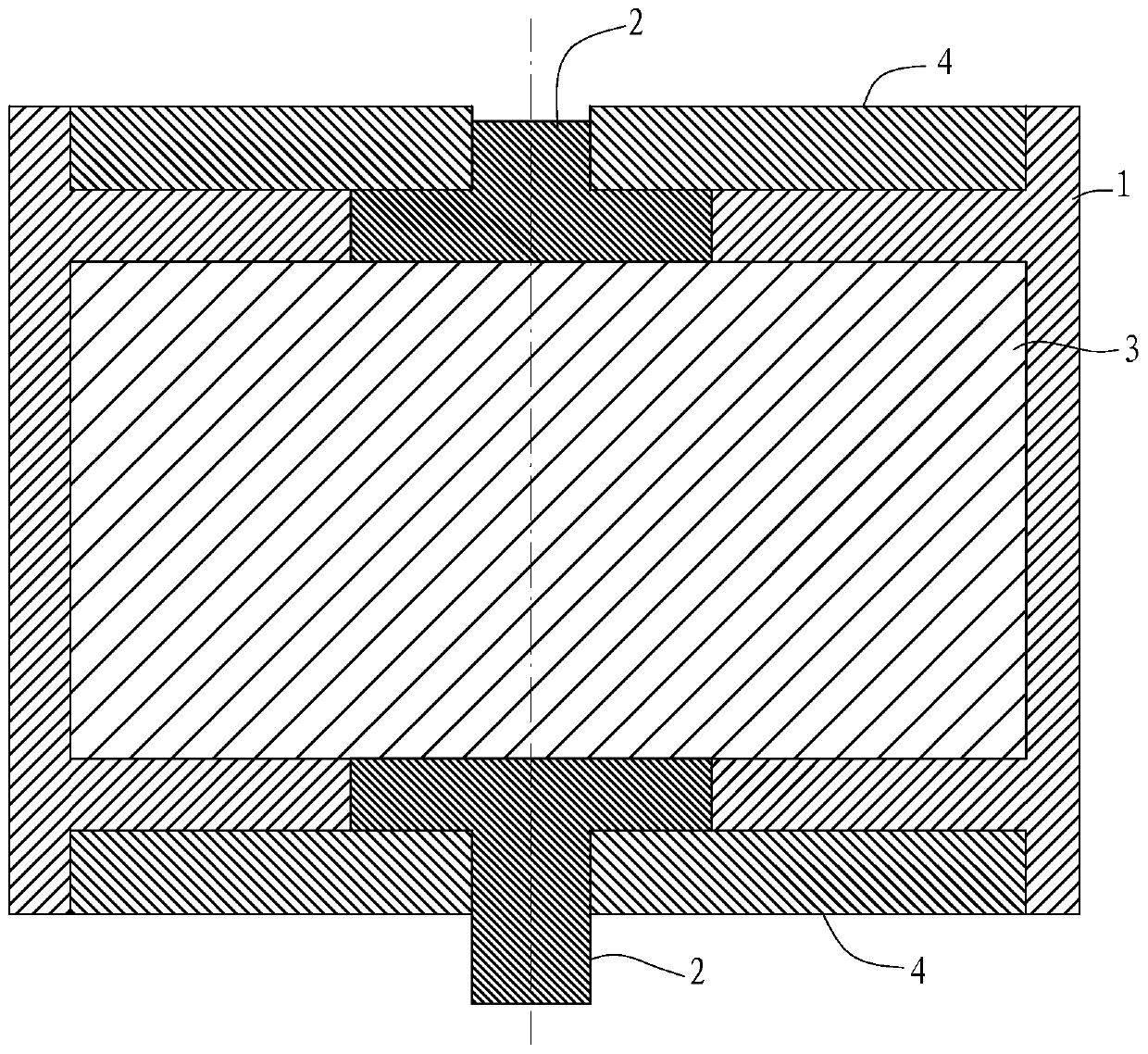

[0022] Such as figure 1 , figure 2 and image 3 As shown, the multifunctional high-pressure pump in this embodiment includes a housing 1, a rotating shaft 2, a compression plate 3 and a pressing plate 4, the housing 1 has a first cavity 11, a second cavity 12 and a working cavity 13, the first Cavity 11 has a fluid inlet channel (not shown in the figure), the second cavity 12 has a fluid outflow channel (not shown in the figure), there is a partition 14 between the first cavity 11 and the second cavity 12, and the working cavity 13 has a suction port 131 communicating with the first cavity 11 and a discharge port 132 communicating with the second cavity. The cross-section of the working cavity 13 in this embodiment is designed to be non-circular.

[0023] The rotating shaft 2 is set in the working cavity 13 of the housing 1 and can rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com