A kind of metallographic sample preparation method

A metallographic sample and crack technology, applied in the field of metallographic sample preparation, can solve the problem of inability to clearly observe the metallographic microstructure, and achieve the effect of uniform corrosion and clear and accurate observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

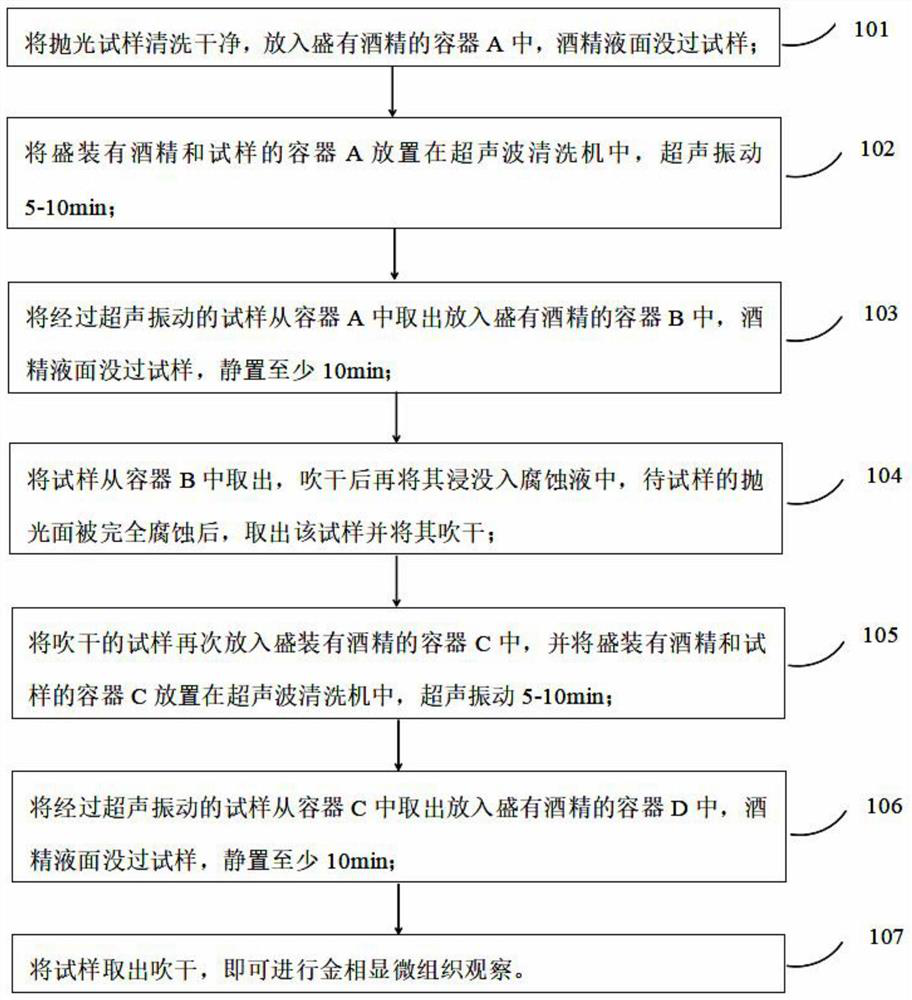

[0041] A metallographic sample preparation method, such as figure 1 shown, including the following steps:

[0042] 101. Clean the polished sample, put it into container A containing alcohol, and the alcohol level does not pass the sample;

[0043] 102. Place the container A containing the alcohol and the sample in the ultrasonic cleaning machine, and ultrasonically vibrate for 5-10min;

[0044] During ultrasonic vibration, if the vibration time is too short, the effect will be poor, and if the vibration time is too long, the sample will easily heat up, which will cause the temperature of the alcohol in the beaker to be too high, the alcohol in the alcohol solution will volatilize, reduce the alcohol concentration, and weaken the water in the crack of the sample. Or the exudation speed of the polishing liquid, so the vibration time should not be too long or too short, preferably 5-10min, more preferably 6-8min, can be 6min, 7min, 8min.

[0045] The vibration frequency is pre...

Embodiment 1

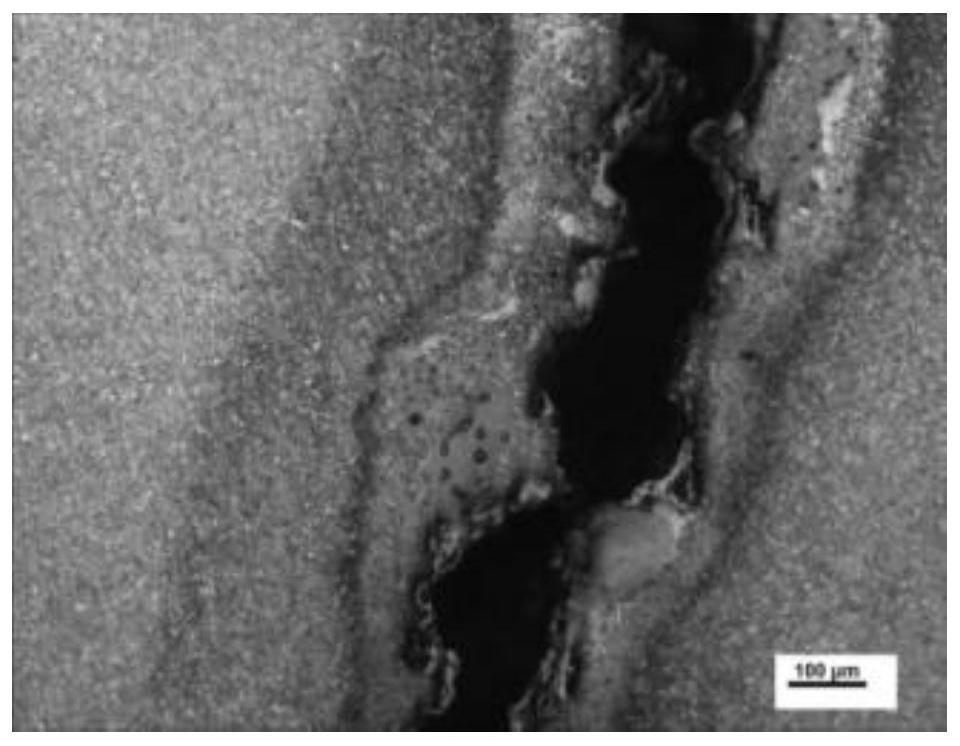

[0064] The 40Cr workpiece produced by a factory was found to have a large number of cracks after quenching, and the crack test block was cut and ground into a metallographic sample, which was observed after corrosion according to conventional methods. figure 2 As shown in the figure, the crack edge is seriously polluted, whether there is decarburization at the crack edge, and whether the structure is normal, it is completely unclear. The conventional method means that the sample is ground by grinding wheel, 600# coarse sandpaper, 1000# sandpaper, rough polishing with 7 micron silicon oxide polishing liquid, fine polishing with 2.5 micron silicon oxide polishing liquid, rinsed with water, rinsed with alcohol, and corroded with corrosive liquid. , alcohol rinse, hair dryer drying.

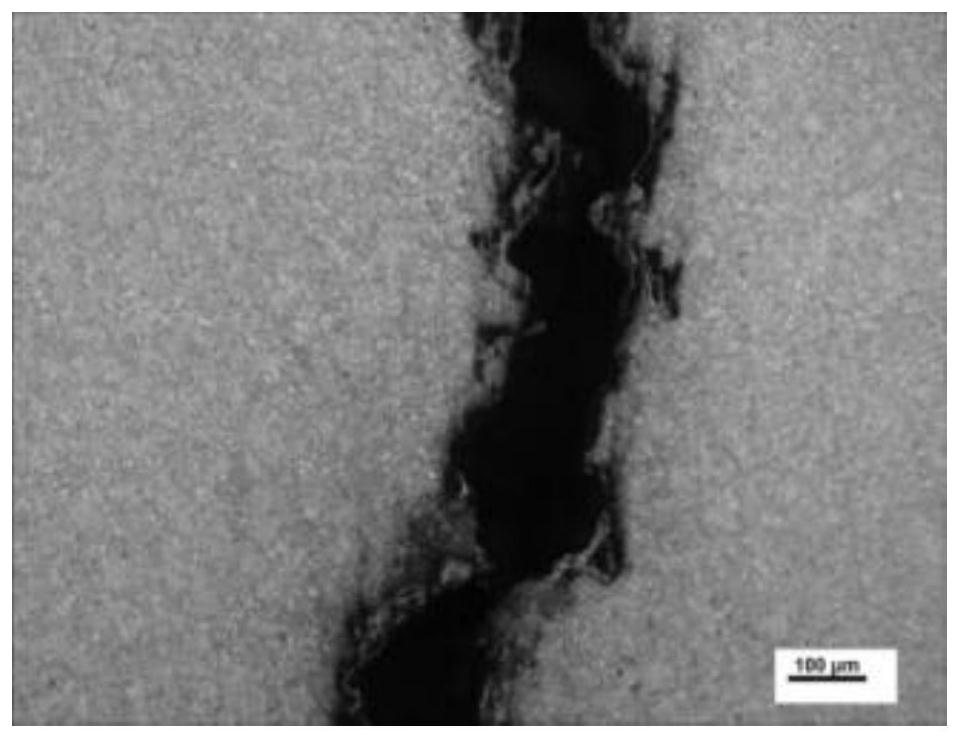

[0065] Use the method provided by the present invention to prepare metallographic samples:

[0066] Cut the cracked part of 40Cr steel as a sample, and then put it into a beaker containing anhydrous...

Embodiment 2

[0069] A 42CrMo workpiece in a factory was found to have cracks on the surface after forging, and the defects were honeycomb-shaped. The defect test block was cut and polished to form a metallographic sample, which was corroded with 2% nitric acid alcohol solution by traditional corrosion methods and observed with a metallographic microscope. Figure 4 As shown, the vicinity of the defect is heavily contaminated and poorly organized. The traditional corrosion method means that the sample is ground by grinding wheel, 600# coarse sandpaper, 1000# sandpaper, rough polishing with 7 micron silicon oxide polishing liquid, fine polishing with 2.5 micron silicon oxide polishing liquid, rinsed with water, rinsed with alcohol, and rinsed with corrosive liquid. Corrosion, alcohol rinse, hair dryer.

[0070] Use the method provided by the present invention to prepare metallographic samples:

[0071] Cut the 42CrMo workpiece defect test block as a sample, and after polishing it with grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com