Oil fume sampling detection device and sampling method thereof

A detection device and oil fume technology, which are applied in measurement devices, suspension and porous material analysis, particle suspension analysis, etc., can solve the problems of reducing oil fume measurement accuracy, weak signal light intensity, weak signal light, etc., and reduce external interference. , low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

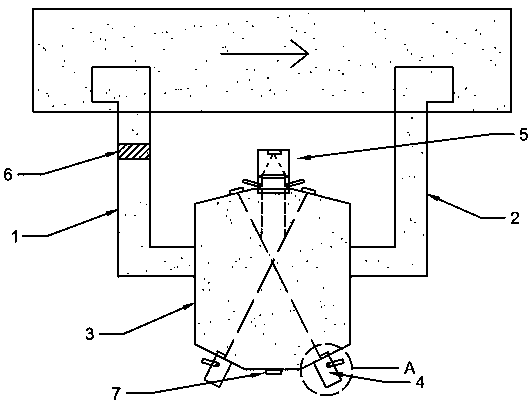

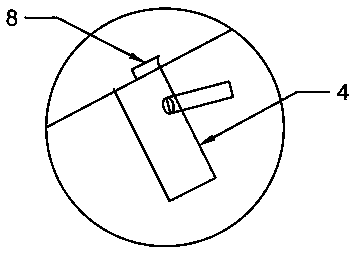

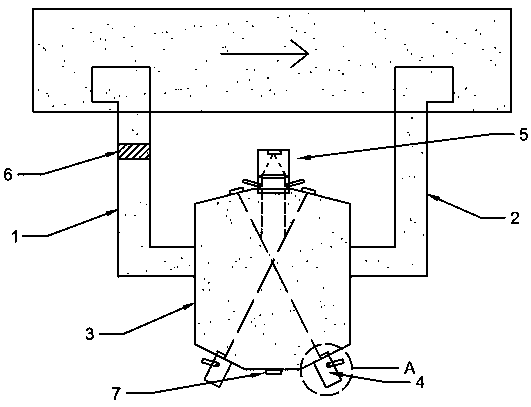

[0025] Embodiment 1: as figure 1 Shown is an oil fume sampling and detection device, including a light emitting module 4, a light receiving module 5, a processing module, an air inlet pipe 1, an air outlet pipe 2 and a sampling box 3, the processing module processes the signal received by the light receiving module 5, and the The sampling box 3 is located outside the smoke exhaust pipe, and is used to store and sample oil fume gas and install the light emitting module 4 and the light receiving module 5; one end of the air inlet pipe 1 is communicated with the exhaust pipe through a sampling hole, and the other end is communicated with the sampling box 3 , for fume gas to flow into the sampling box 3 from the exhaust pipe; one end of the outlet pipe 2 communicates with the sampling box 3, and the other end communicates with the exhaust pipe through a sampling hole, and is used for the fume gas to flow out from the sampling box 3 to the exhaust pipe. smoke pipes. Through the ab...

Embodiment 2

[0032] Embodiment 2: The basic structure of this embodiment is the same as that of Embodiment 1, and the difference is that the installation holes connecting the inlet pipe 1 and the outlet pipe 2 on the sampling box 3 are not on the same straight line (not drawn). That is, the setting of the installation holes on the sampling box 3 is not symmetrical. This design can make the oil fume gas introduced by the inlet pipe 1 change direction in the sampling box 3 before it can flow out from the outlet pipe 2, so that the oil fume gas can fully stay and diffuse, and the detection rate can be improved. the accuracy rate.

[0033] In addition, it also includes a sampling method of an oil fume sampling and detection device, which is suitable for the above-mentioned oil fume sampling and detection device, including the following steps:

[0034] S1: In the preparation stage, adjust the mesh aperture of the filter unit to 2 μm, turn on the fan blade exhaust fan to evacuate the large parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com