Fire-resistant anti-flaming optical cable and preparation method thereof

A fire-resistant and flame-retardant optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of large optical fiber transmission loss, brittle fracture of optical cable, distortion, etc., achieve good impact resistance and tear strength, small melting processing characteristics, The effect of high flame resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1

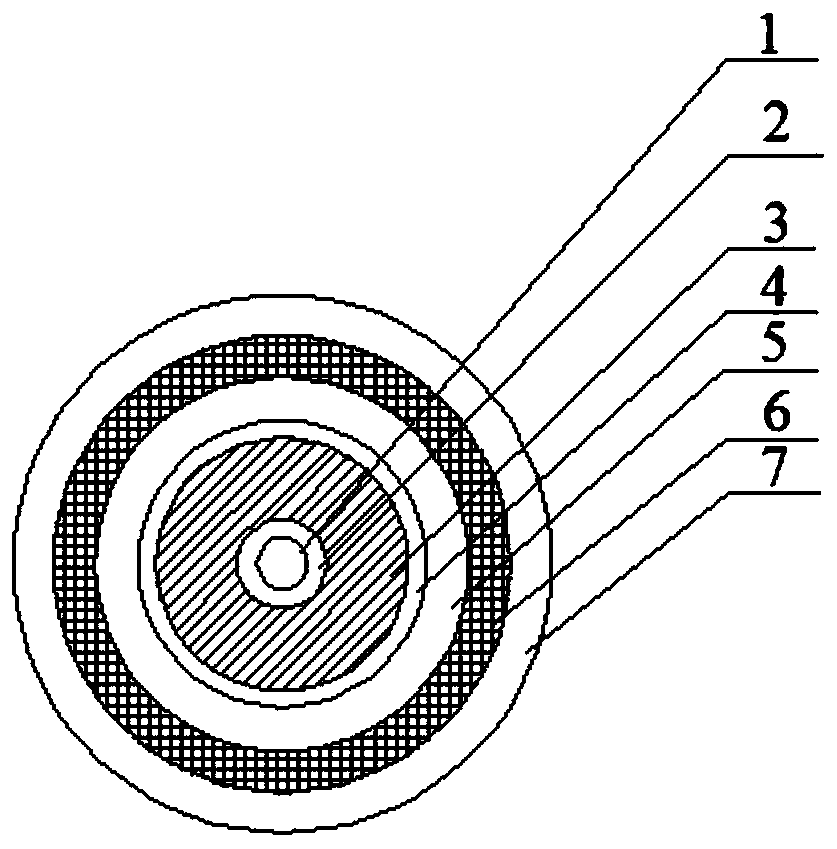

[0034] like figure 1 As shown, a fire-resistant and flame-retardant optical cable includes a cable core 1, a protective layer coated outside the cable core, a refractory layer 5 coated outside the outer protective layer, and a sheath layer coated outside the refractory layer, wherein the Described protective layer is inner protective layer 2, intermediate protective layer 3 and outer protective layer 4 three layers, and described inner protective layer 2 is the polyimide coating that thickness is 30-40 μ m, and described intermediate protective layer 3 is that thickness is 1-2mm polyaryletherketone-polysiloxane / polyimide copolymer coating, the outer protective layer 4 is a thermotropic liquid crystal copolyester PET / PHB coating with a thickness of 10-20 μm; The refractory layer 5 is a ceramic polyimide composite tape with a thickness of 0.12-0.2 mm; the sheath layer includes an inner sheath layer 6 and an outer sheath layer 7, and the inner sheath layer 6 h...

Example Embodiment

[0036] Example 2

[0037] like figure 1 As shown, a fire-resistant and flame-retardant optical cable includes a cable core 1, a protective layer coated outside the cable core, a refractory layer 5 coated outside the outer protective layer, and a sheath layer coated outside the refractory layer, wherein the Described protective layer is inner protective layer 2, intermediate protective layer 3 and outer protective layer 4 three layers, and described inner protective layer 2 is the polyimide coating that thickness is 30-40 μ m, and described intermediate protective layer 3 is that thickness is 1-2mm polyaryletherketone-polysiloxane / polyimide copolymer coating, the outer protective layer 4 is a thermotropic liquid crystal copolyester PET / PHB coating with a thickness of 10-20 μm; The refractory layer 5 is a ceramic polyimide composite tape with a thickness of 0.12-0.2 mm; the sheath layer includes an inner sheath layer 6 and an outer sheath layer 7, and the inner sheath layer 6 h...

Example Embodiment

[0039] Example 3

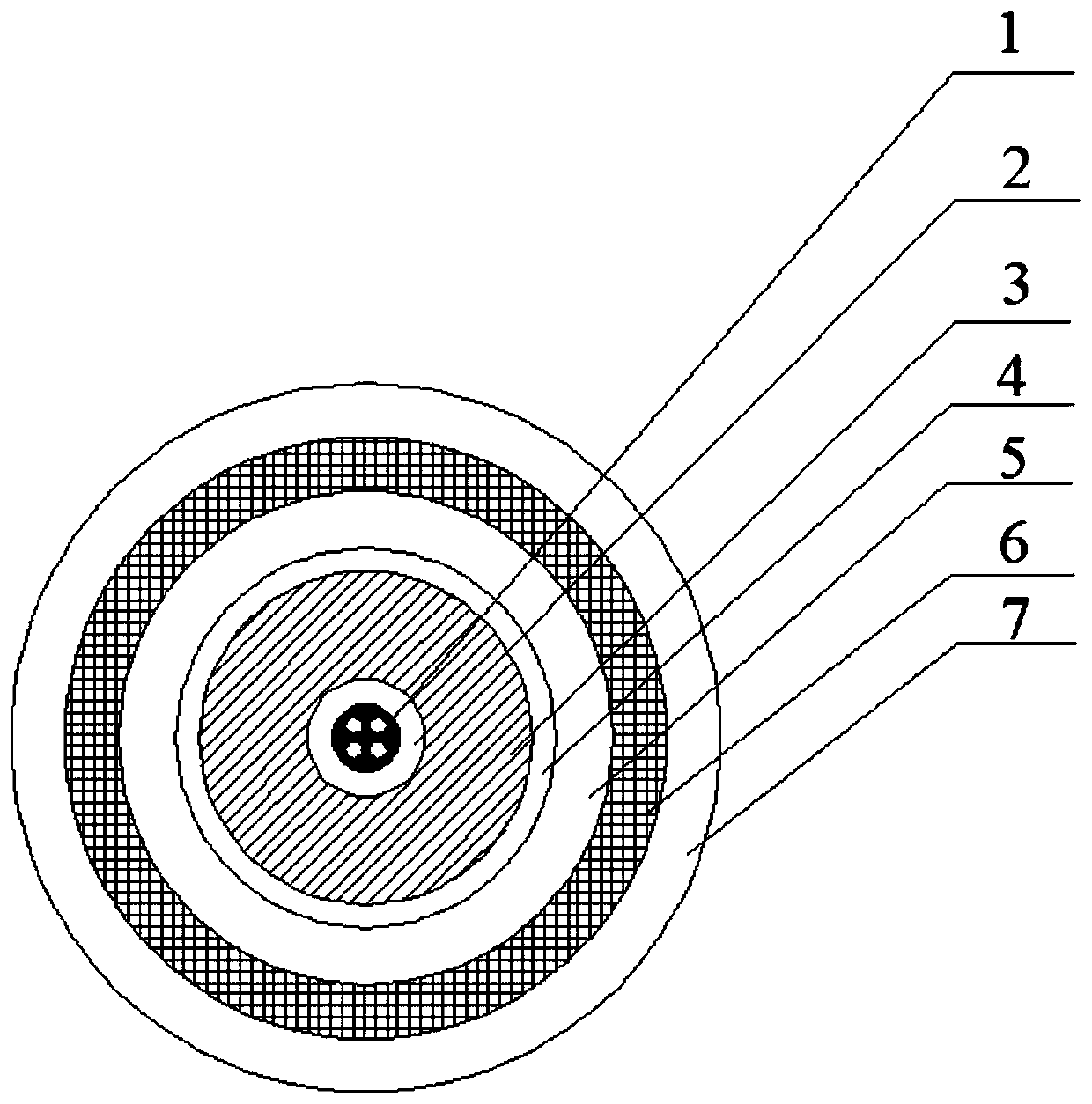

[0040] like figure 2 As shown, a fire-resistant and flame-retardant optical cable includes a cable core 1, a protective layer coated outside the cable core, a refractory layer 5 coated outside the outer protective layer, and a sheath layer coated outside the refractory layer, wherein the Described protective layer is inner protective layer 2, intermediate protective layer 3 and outer protective layer 4 three layers, and described inner protective layer 2 is the polyimide coating that thickness is 30-40 μ m, and described intermediate protective layer 3 is that thickness is 1-2mm polyaryletherketone-polysiloxane / polyimide copolymer coating, the outer protective layer 4 is a thermotropic liquid crystal copolyester PET / PHB coating with a thickness of 10-20 μm; The refractory layer 5 is a ceramic polyimide composite tape with a thickness of 0.12-0.2 mm; the sheath layer includes an inner sheath layer 6 and an outer sheath layer 7, and the inner sheath layer 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com