Isothermal adsorption device and test method for changing gas density

A gas density, isothermal adsorption technology, applied in the field of experimental equipment, can solve the problems of no isothermal adsorption device that can be used to change the gas density, can not do isothermal adsorption experiments, etc., to achieve the effect of easy promotion, good use effect, and reduce experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

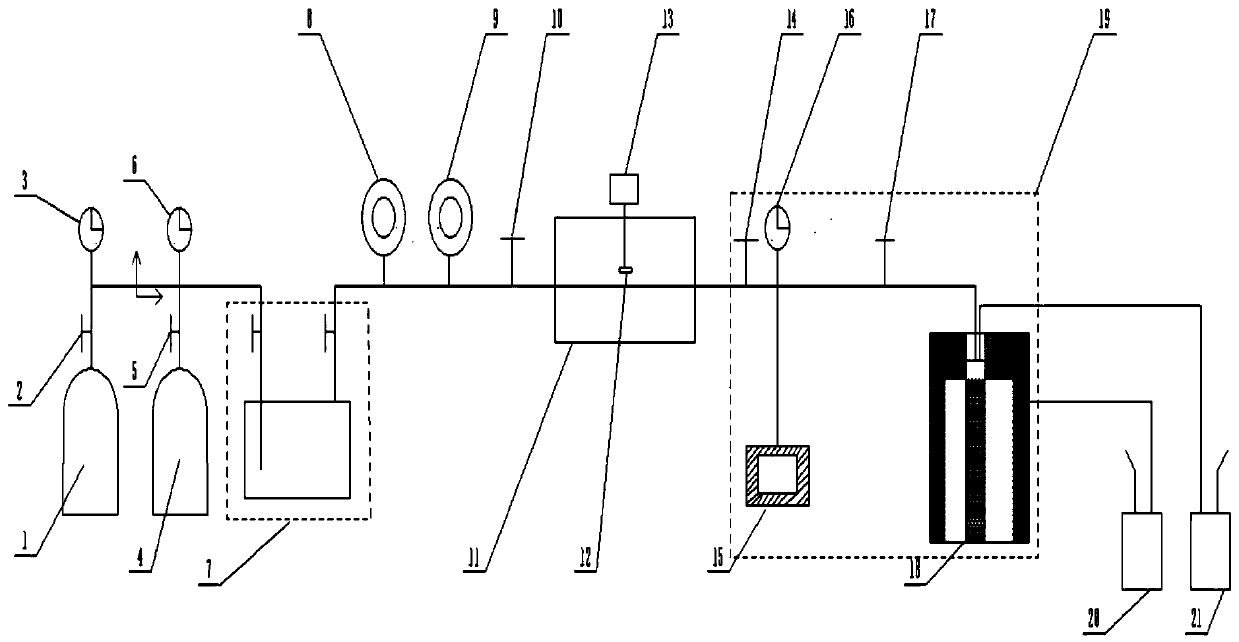

[0021] see Figure 1-2

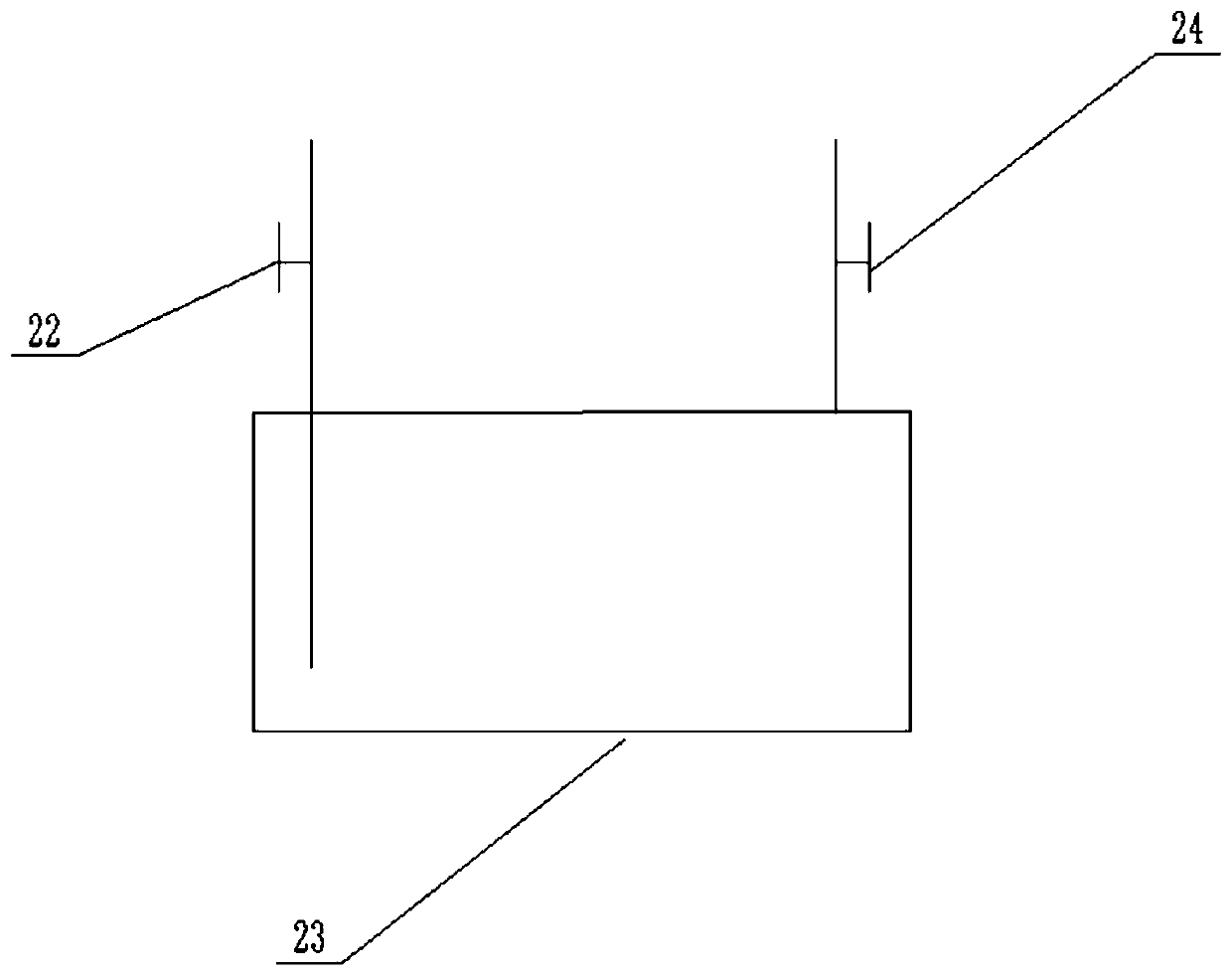

[0022] An isothermal adsorption device for changing gas density, which includes: a mixed gas supply system, the mixed gas supply system is connected to the gas mixing device 7 through pipelines; the gas mixing device 7 is connected to the gas density measuring mixing box 11 through pipelines; The gas density measuring mixing box 11 is connected to the gas adsorption system through pipelines; the gas adsorption system is connected to the pressure loading system through pipelines; the gas density measuring mixing box 11 is equipped with a gas density sensor 12, and the gas density sensor is connected to the display through a wire 13 connections.

[0023] The mixed gas supply system includes a first gas storage tank 1 and a second gas storage tank 4; the pipeline connecting the first gas storage tank 1 and the gas mixing device 7 is sequentially installed with a first on-off valve 2 and a first pressure gauge 3 ; The second on-off valve 5 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com