System and method for realizing high-precision orthogonality adjustment of image surface of star sensor

A star sensor and adjustment system technology, applied in the direction of instruments, optical components, optics, etc., can solve the problems of low efficiency and low adjustment accuracy of the adjustment method, save adjustment time, quantify the measured parameter index, and shorten the installation and adjustment The effect of the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

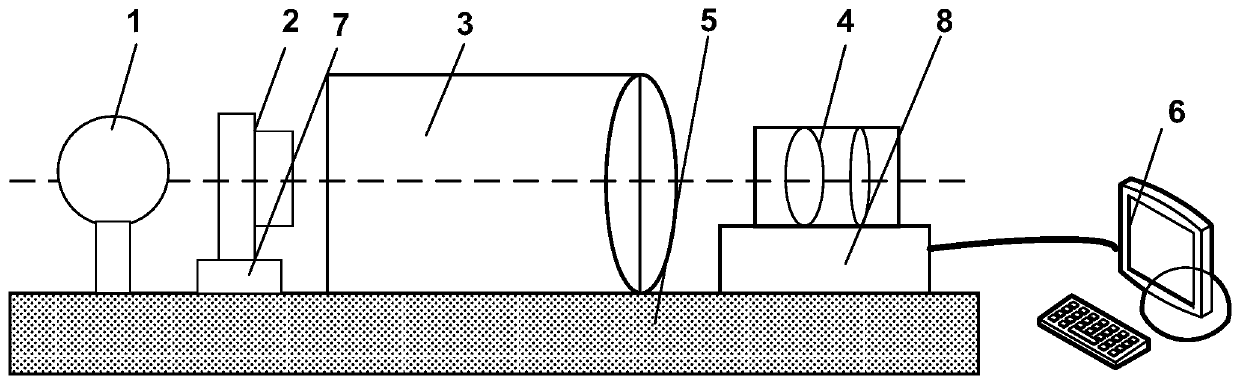

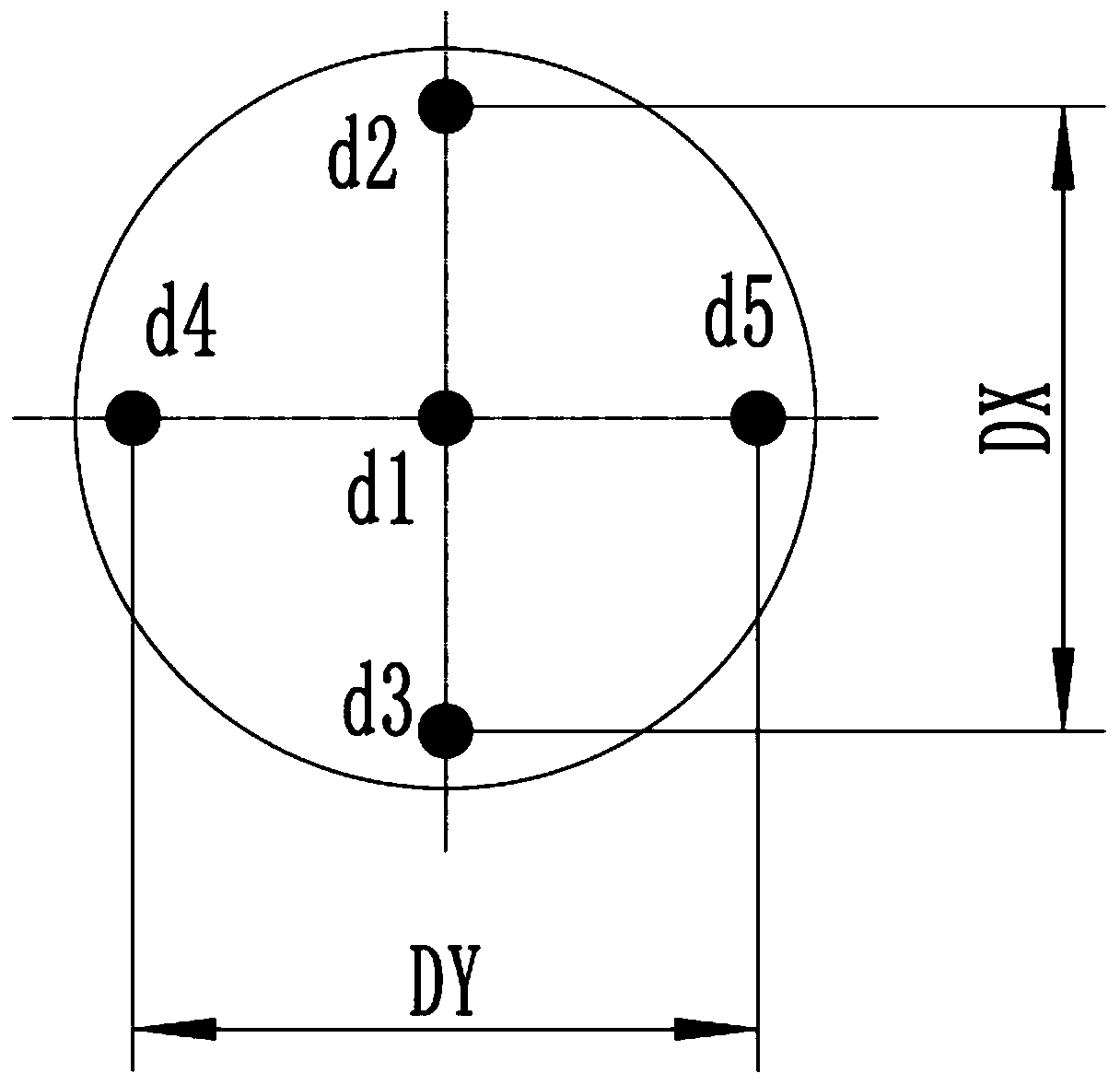

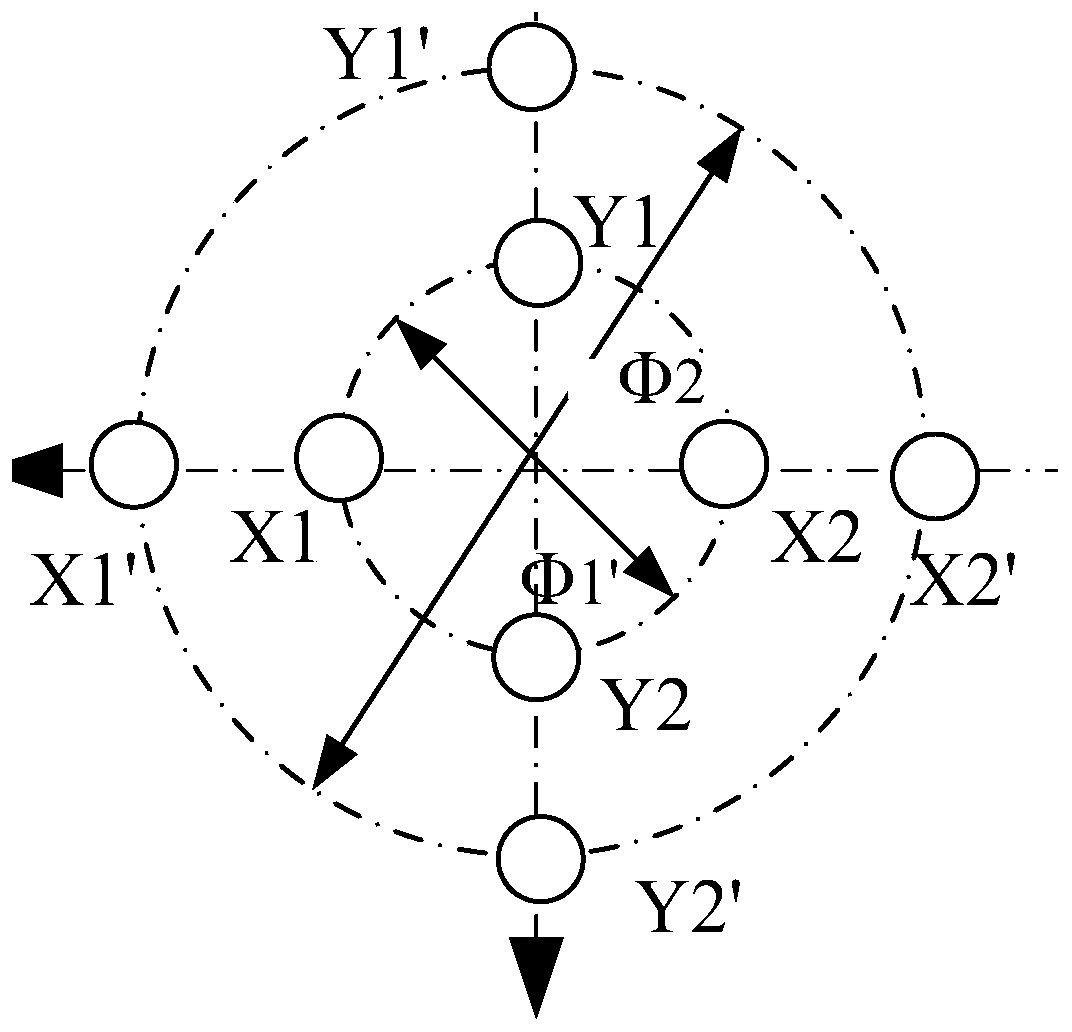

[0040] If the detector image plane of the star sensor is tilted relative to the optical axis of the system, so that the pixels in the detector image plane are not on the same vertical focal plane, resulting in the image plane imaging showing a pre-focus and back-focus state, and the centroids at different fields of view Changes will affect the measurement accuracy of the star sensor, so it is very important to realize the orthogonal adjustment of the detector and the optical axis of the system. The invention provides a high-precision orthogonality adjustment system and adjustment method for the star sensor image plane, through which the system optical axis of the star sensor and the detector image plane can be adjusted for high-precision orthogonal alignment, and the quantization is achieved. Measure parameter indicator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com