Method for evaluating diffusion degree of regenerant in waste asphalt mixture

A technology of waste asphalt and diffusion degree, applied in the field of molecular dynamics simulation, can solve the problem that it is difficult to better characterize the diffusion status of regenerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] When T=383K, evaluate the diffusion degree of regenerant 1 in waste asphalt mixture. The specific implementation process is as follows:

[0050] 1) Draw the molecular structure of the regenerant in MS, and then use the Forcite function in the Modules module to optimize the molecular structure of the constructed three-dimensional structure, and determine the minimum energy conformation of the regenerant;

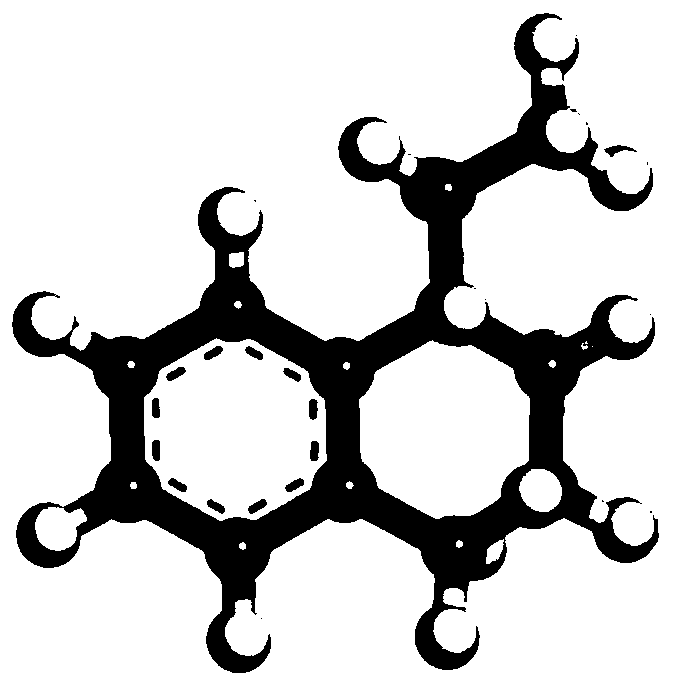

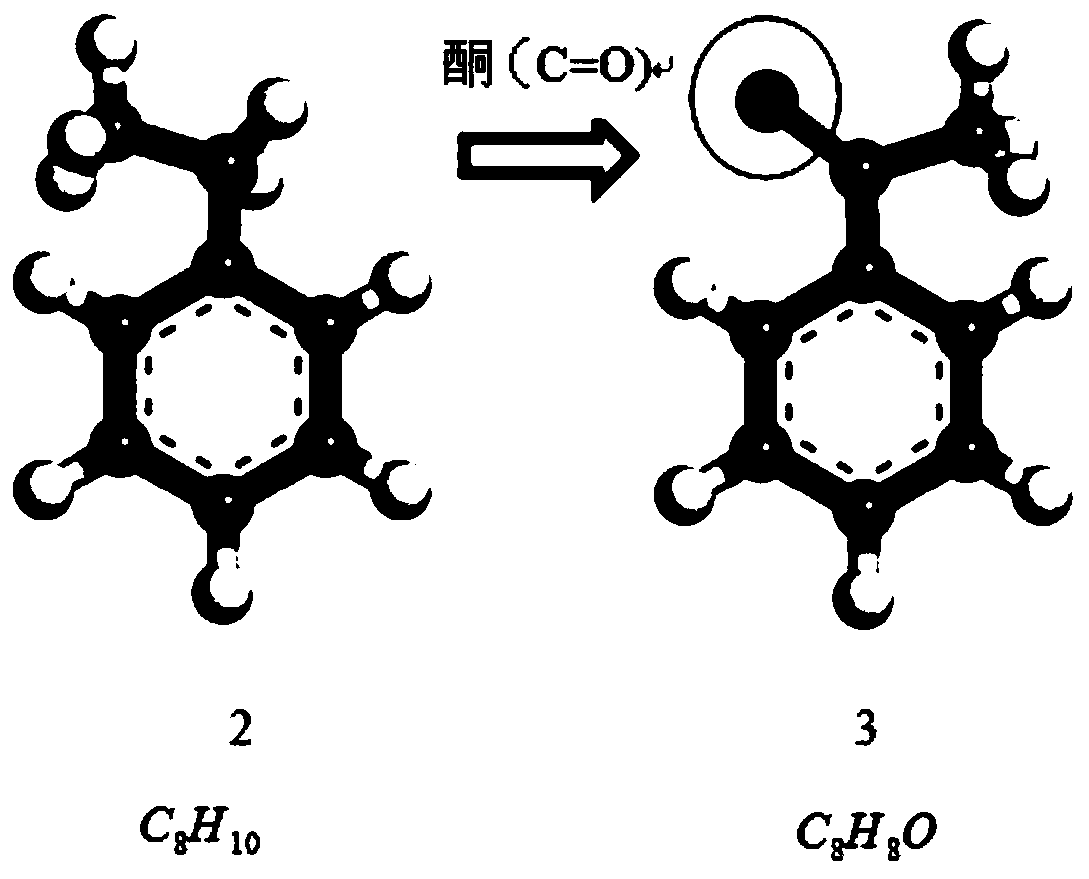

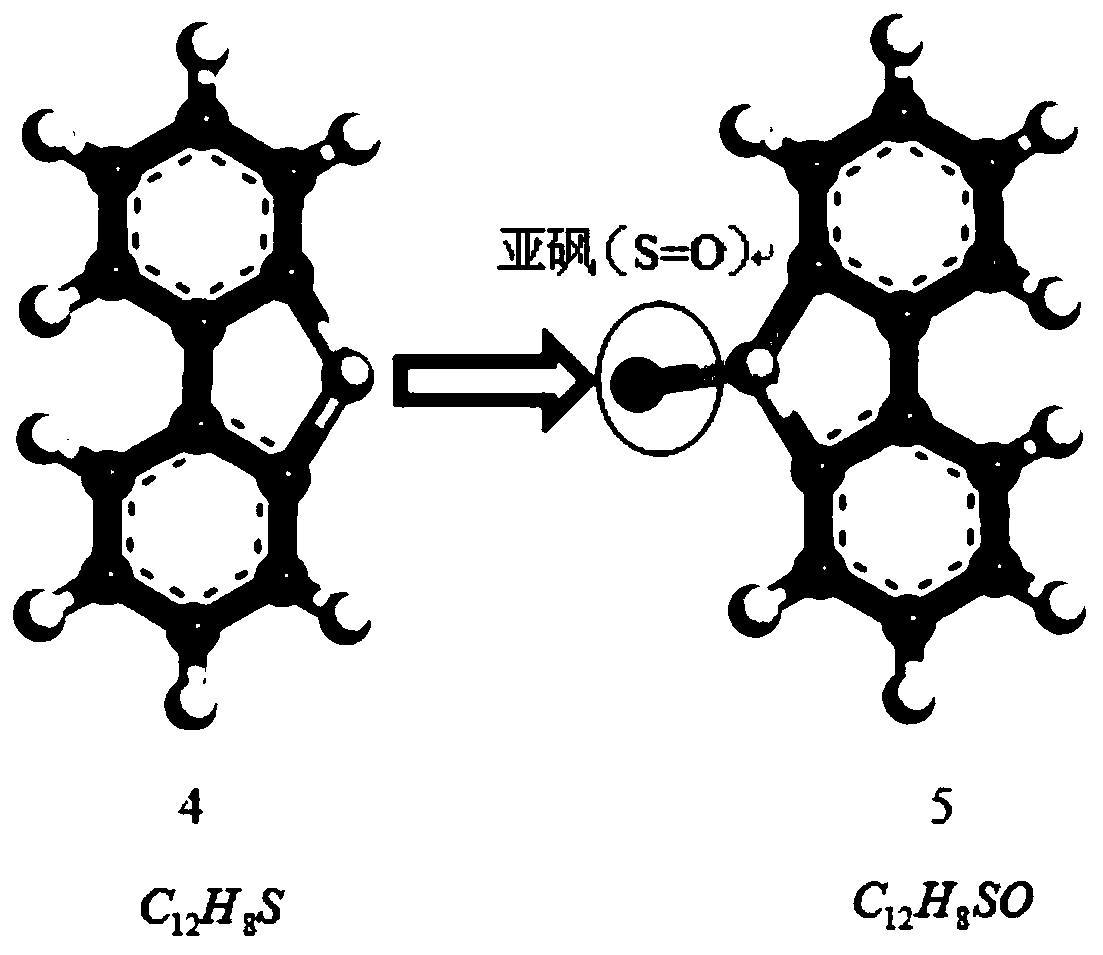

[0051] 2) Use twelve kinds of molecules to form the molecular structure of RAP, then add ketone and sulfoxide functional groups to characterize the aging, and then use the Forcite function in the Modules module to optimize the molecular structure of the constructed three-dimensional structure, and determine the conformation of the minimum energy of RAP;

[0052] 3) In the COMPASS2 force field, use the Amorphous cell function in the Modules module of the MS software to construct the confinement layer of the regenerative agent and RAP with the three-dimensional structure ...

Embodiment 2

[0057] When T=433K, evaluate the diffusion degree of the regenerant in the waste asphalt mixture, and the specific implementation process is the same as that in Example 1. The density distribution curve of regeneration agent 1 of the present invention at T=433K is as follows Figure 8 As shown, the density distribution curve of regeneration agent 1 of the present invention at T=433K is multiplied by t -0.5 Such as Figure 9 shown.

[0058] After calculation, when T=433K, the diffusion coefficient D of regenerant in RAP 0 =9.63×10 -6 cm 2 / s.

Embodiment 3

[0060] When T=533K, evaluate the diffusion degree of the regenerant in the waste asphalt mixture. The specific implementation process is the same as in Example 1. After calculation, when T=533K, the diffusion coefficient D of the regenerant in RAP 0 =4.56×10 -5 cm 2 / s.

[0061] In the above example, the diffusion coefficient of the regenerant in RAP is calculated by simulation software, so as to evaluate the diffusion degree of the regenerant in RAP from a microscopic molecular perspective. It can be seen that the higher the temperature, the greater the diffusion coefficient of the regenerant in RAP. At present, most of the methods for calculating the diffusion coefficient by using simulation software are to calculate the diffusion coefficient by obtaining the curve of root mean square displacement (MSD) and time, but this method is only applicable to some models. For the double layer of regenerant and RAP The model cannot use the root mean square displacement curve to find...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com