Preparation method of colored rubber stair tread and rubber stair tread

A technology of stair treads and rubber, applied in the field of rubber flooring, to improve product quality and life, save product costs, and reduce man-hour consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

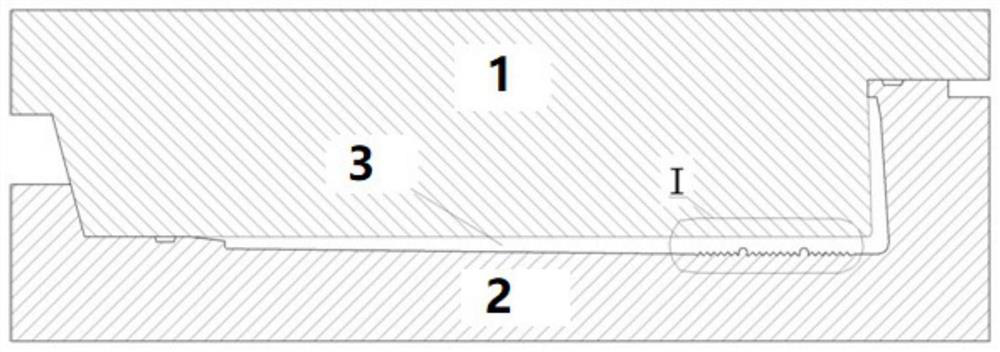

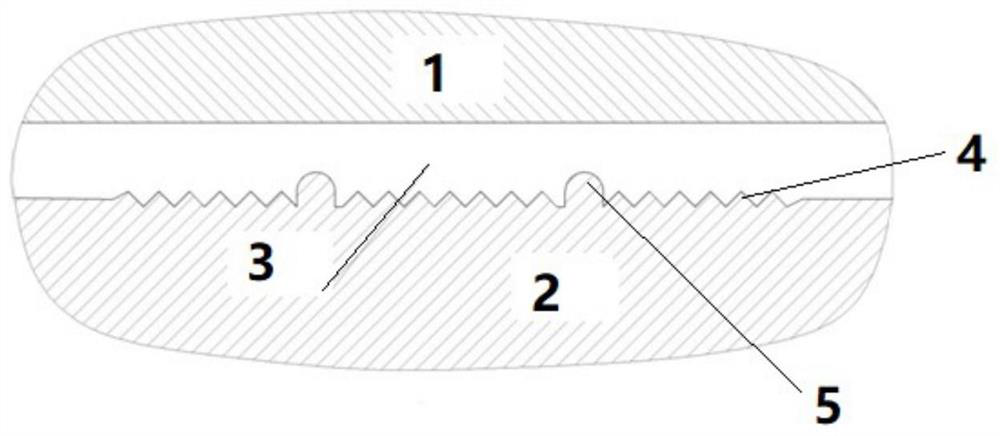

[0049] Mold design: such as Figure 1-3 shown.

[0050] The lower mold of the colored rubber stair treads is provided with a sawtooth pattern; according to the design width of the warning line film, ribs are set on both sides of the sawtooth pattern, and the width of the tooth-shaped mold cavity formed by the two ribs is equivalent to the width of the warning line film; the width is 15mm.

[0051] The zigzag pattern has a depth of 1 mm, a tooth pitch of 2 mm, and a tip angle of 90°.

[0052] The rib is a rib with a semi-circular arc in section; the height of the rib is 1.75 mm; the width of the rib is 2.5 mm.

[0053] The warning line film (yellow) is put into the tooth-shaped mold cavity formed by the rib; the main film (gray) is covered on the warning line film, and the mold is closed and vulcanized once to form.

[0054] Specific preparation process:

[0055] 1. Film preparation:

[0056] (1) in The extruder extrudes a rubber strip with a thickness of 4-5mm and a wid...

Embodiment 2

[0063] Mold design is with embodiment 1;

[0064] Preparation process is with embodiment 1;

[0065] The difference is: the vulcanization temperature is 150°C; the vulcanization time is 12 minutes;

[0066]The warning line of the prepared rubber stair tread is yellow, the main film is green, the boundary of the warning line is clear and straight, and after co-vulcanization, the warning line film and the main film are an integral structure, which will not fall off during use.

Embodiment 3

[0068] Mold design is with embodiment 1;

[0069] Preparation process is with embodiment 1;

[0070] The difference is: the vulcanization temperature is 170°C; the vulcanization time is 9 minutes;

[0071] The warning line of the prepared rubber stair tread is green, the main film is gray, the boundary of the warning line is clear and straight, and after co-vulcanization, the warning line film and the main film are an integral structure, which will not fall off during use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com