Flanging riveting device and method for outward expansion joint bearing

A joint bearing and flanging technology, which is applied in the field of the expansion joint bearing flanging and riveting device, can solve the problems of the tightness of the inner and outer rings of the joint bearing, the upsetting deformation of the outer ring of the joint bearing, and the increase of the starting torque, and the process is easy to achieve. , avoid upsetting deformation, the effect of simple tool structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

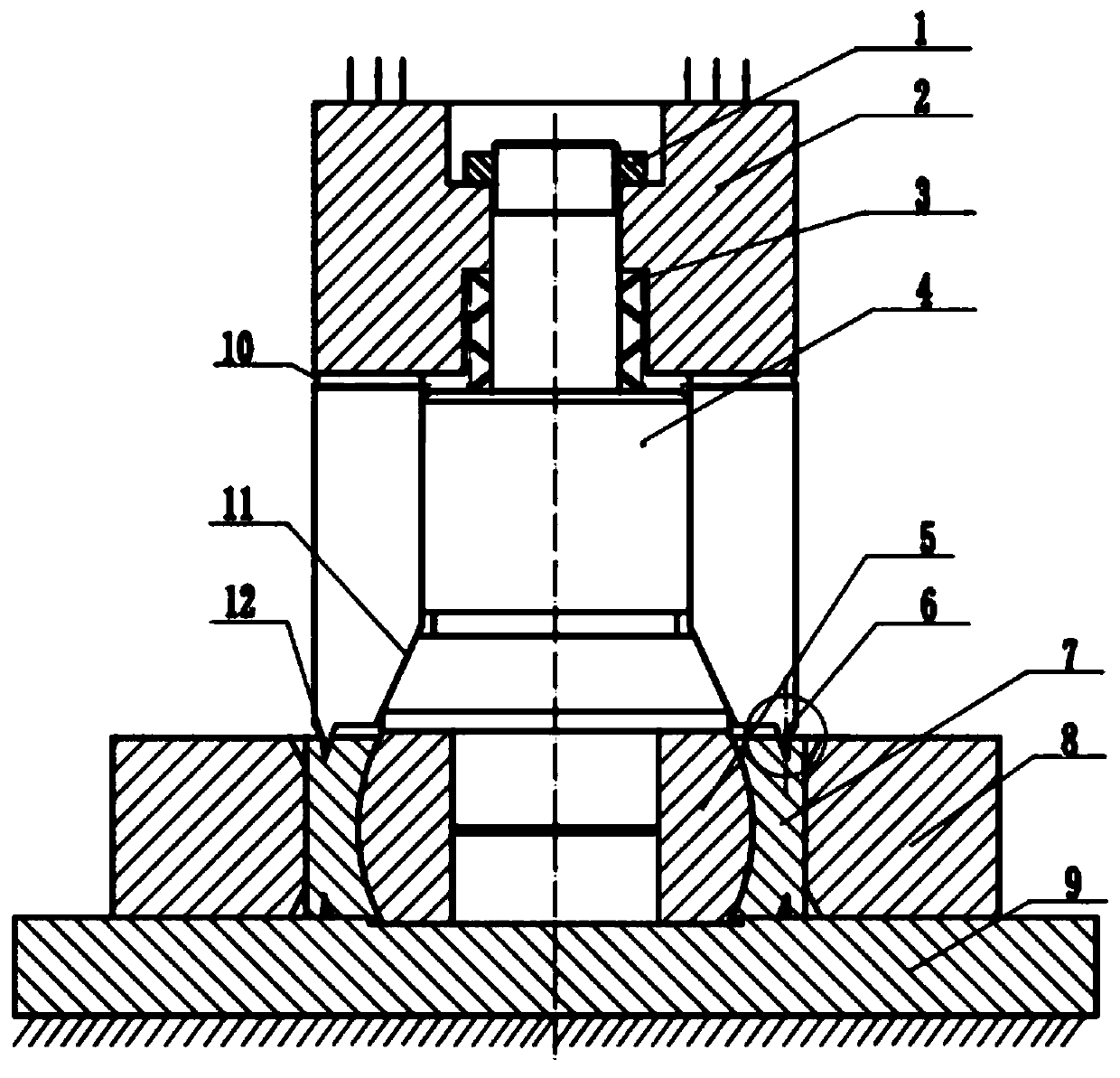

[0048] figure 1 It is a schematic diagram of a joint bearing pressure riveting method and tools, which includes a nut 1, a pressure riveting head 2, a mandrel 4 and a wave spring 3, the nut 1 is arranged on the mandrel 4, and the configuration of the nut 1 is used to adjust the tension of the wave spring 3.

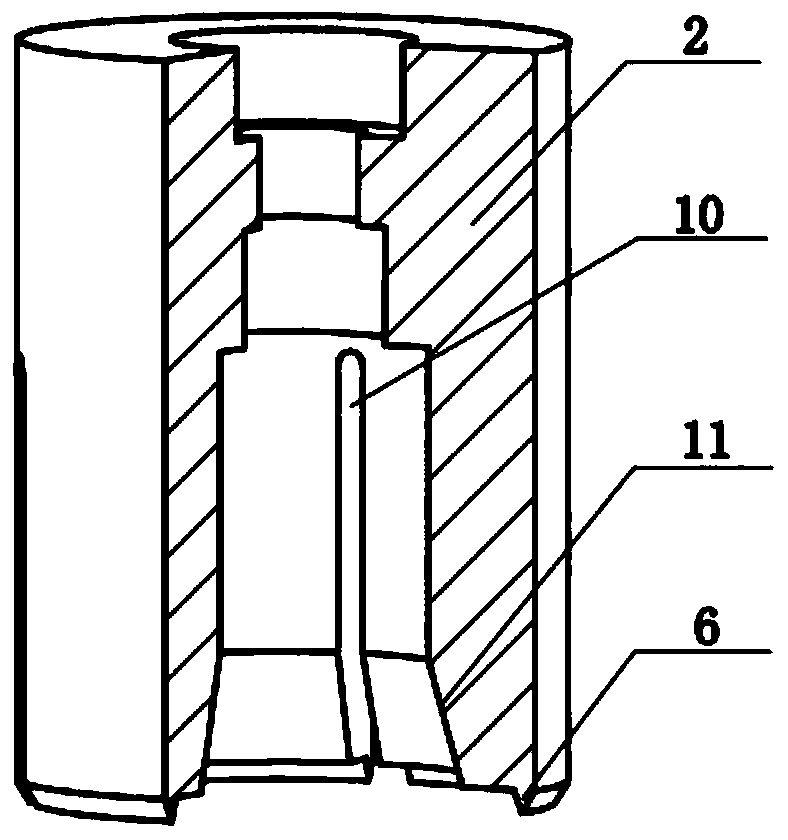

[0049] The tip of the riveting head 2 and its lower end are provided with six slots 10 evenly distributed along the circumference. The configuration of the slots 10 is used to make the riveting head 2 move relative to the cone surface relative to the mandrel 4 so as to produce a radial outer surface. expansion movement.

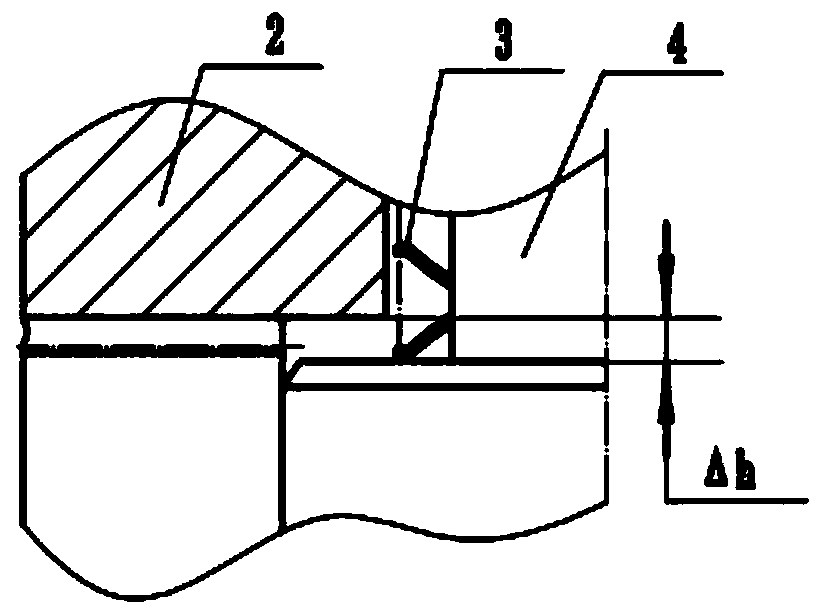

[0050] like figure 2 As shown, by adjusting the nut 1 to compress the wave spring 3, the distance between the riveting head 2 and the end face of the large cylinder is adjusted to Δh, and the initial positioning of the riveting head 2 is determined; 4, through the conical surface fit 11, the slot 10 of the pressure riveting head and the end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com