A hot extrusion molding process for aluminum alloy mobile phone shell

A molding process and mobile phone case technology, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor aesthetics and poor protection of aluminum alloy mobile phone cases, and achieve increased strength and toughness, improved aesthetics, and manufacturing processes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0024] Embodiments of the invention are:

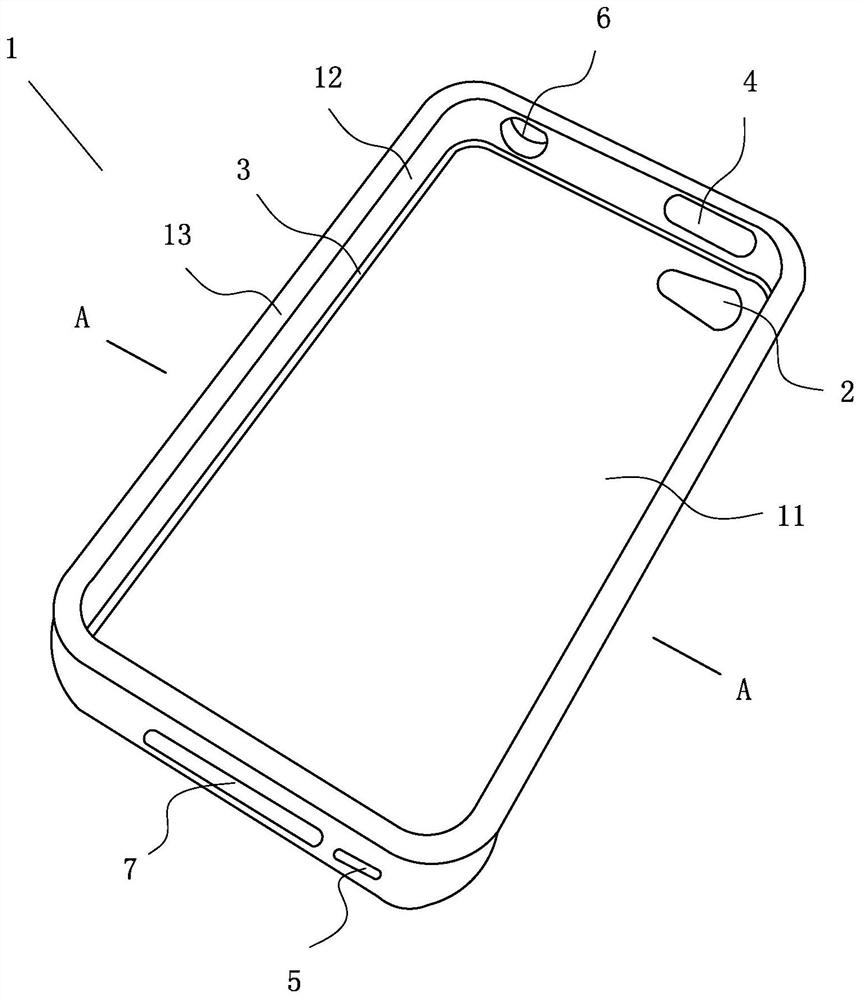

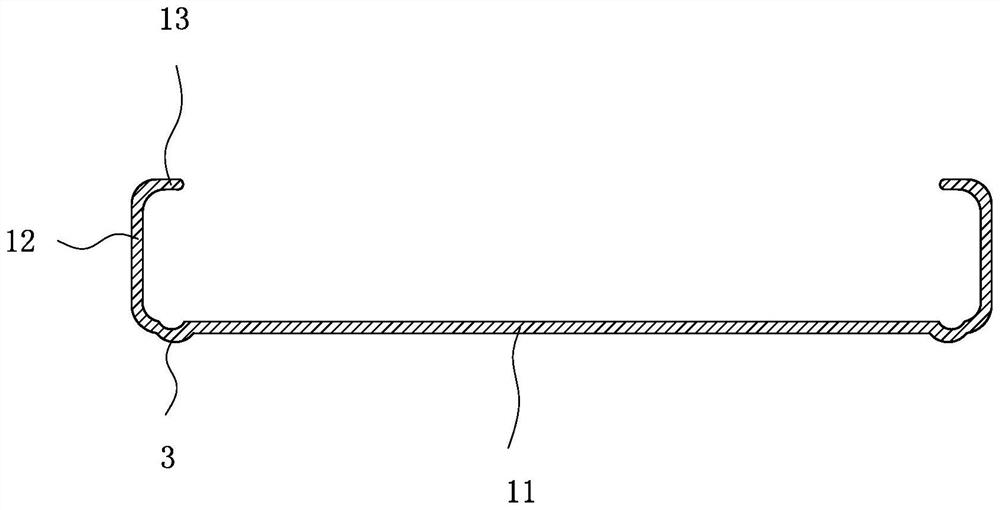

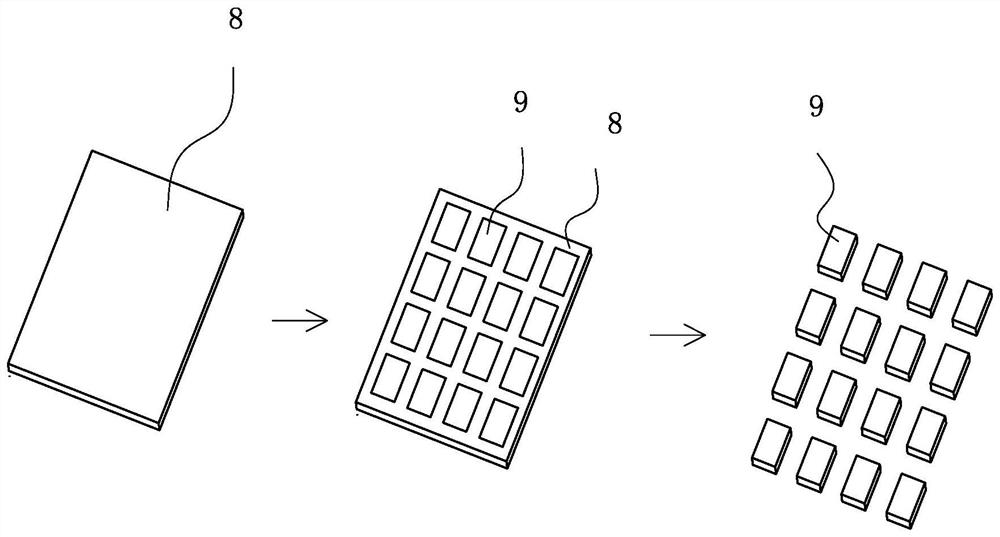

[0025] refer to figure 1 , figure 2 and image 3 , a plate hot extrusion molding process for an aluminum alloy mobile phone case, including a mobile phone case body 1, the mobile phone case body 1 includes a bottom plate 11, the periphery of the bottom plate 11 is bent upward to form a side wall 12, and the side wall 12 The upper edge of the wall 12 is bent inward to form an edge 13 for buckling the upper surface of the mobile phone. The bottom plate 11 is provided with a camera through hole 2, and the connection between the periphery of the bottom plate 11 and the side surface 12 is concave downward. An annular protrusion 3 is provided, and the side wall 12 is respectively provided with a button through hole 4, a charging through hole 5, an earphone through hole 6 and an audio through hole 7, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com