Assembly type crash barrier special for road

An anti-collision barrier, assembled technology, applied in the direction of roads, roads, road safety devices, etc., can solve the problem of the limited deformation ability and energy absorption ability of the guardrail, the limited deformation ability and energy absorption ability, and the safety of vehicles and crew. It can solve problems such as secondary damage, and achieve the effect of convenient industrialization and disassembly, good coordination and connection performance, and fast assembly speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

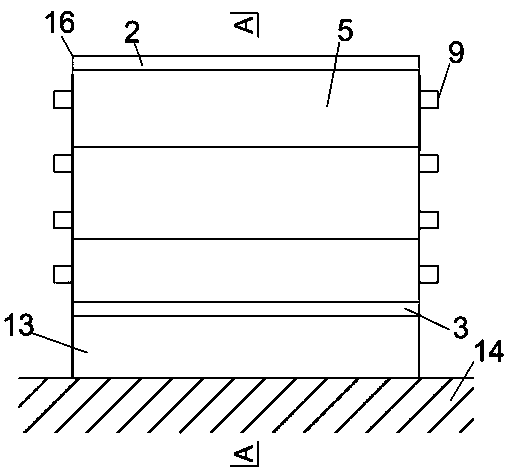

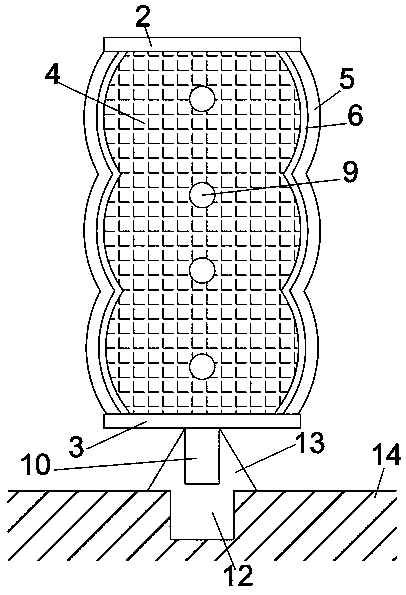

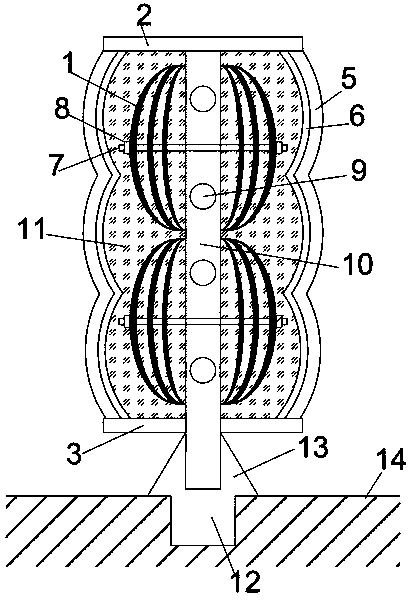

[0021] Example: such as Figure 1~Figure 7 As shown, a prefabricated anti-collision barrier for roads, including high-efficiency energy-consuming curved soft steel plate 1, upper sealing plate 2, lower sealing plate 3, end plate 4, anti-collision protection pad 5, light-weight outsourcing soft steel plate 6, Cable 7, fixing bolt 8, connecting beam 9, concrete base plate 10, lightweight energy-dissipating material 11, reinforced foundation 12, reinforced base 13, ground 14, connector 15, anti-collision barrier unit 16, smooth transition connection soft Plate 17, energy dissipation connecting spring 18, bulging soft plate 19 and end plate 20;

[0022] In the structure of the prefabricated anti-collision barrier for roads, a reinforcement foundation 12 is provided under the ground 14, a reinforcement base 13 is provided on the top of the reinforcement foundation 12, and an upper sealing plate 2, a lower sealing plate 3, an end The main structure of the anti-collision fence surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com