Assembly type crash barrier connection system for sharp turn

A prefabricated anti-collision barrier technology, which is applied in road safety devices, roads, roads, etc., can solve the problem of limited deformation capacity and energy absorption capacity of guardrails, limited deformation capacity and energy absorption capacity, and secondary safety problems of vehicles and crew members. Injury and other problems, to achieve the effect of convenient industrial disassembly, low construction cost, and fast assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

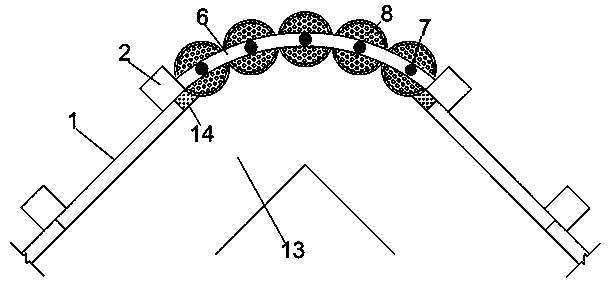

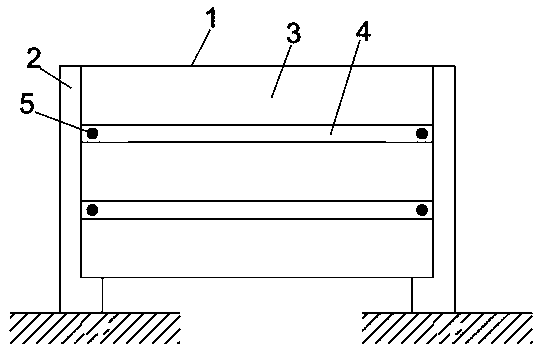

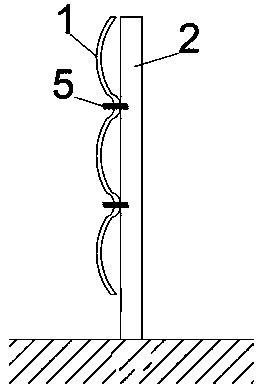

[0022] Example: such as Figure 1~Figure 8 As shown, an assembly-type anti-collision barrier connection system for sharp turns, including a light energy-dissipating buffer guardrail 1, a column 2, a drum-shaped energy-dissipating plate 3, a transition connection energy-dissipating plate 4, a connecting piece 5, a curved Connecting railings 6, connecting fixed rods 7, rotating energy-dissipating barrels 8, outer cylinders 9, inner cylinders 10, rubber energy-dissipating layers 11, hollow areas 12, sharp turning roads 13, transitional connection rubber columns 14, connecting surfaces 15 and cut joints Rotate the adaptation surface 16; set some columns 2 on the outside of the sharp turn road 13, set two curved connecting railings 6 between the two columns 2 in the middle, and connect and fix the two ends of the curved connecting railings 6 with the columns 2, and set some connecting rails Fixed rod 7, its two ends are fixed through the curved connecting railing 6, and the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com