Assembly type light energy dissipation fence

A prefabricated, lightweight technology, used in road safety devices, roads, roads, etc., can solve the problem of limited deformation ability and energy absorption ability of guardrails, limited deformation ability and energy absorption ability, and safety of vehicles and crew. Injury and other problems, to achieve the effect of convenient industrialization and disassembly, good coordination and connection performance, and fast assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

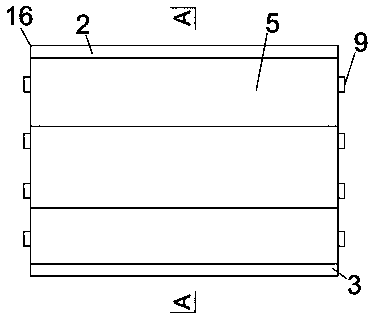

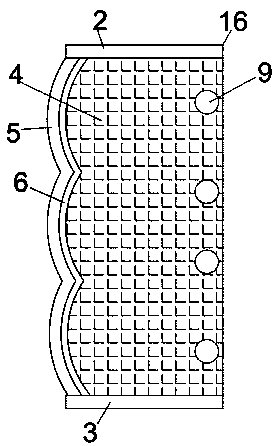

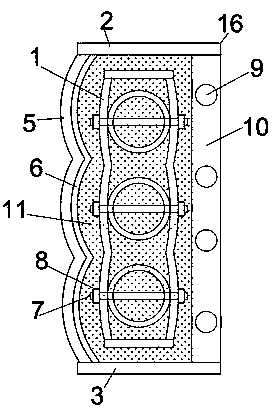

[0019] Example: such as Figure 1~Figure 6 As shown, an assembled lightweight energy-dissipating guardrail includes an energy-dissipating composite structure 1, an upper sealing plate 2, a lower sealing plate 3, an end plate 4, an anti-collision protection pad 5, a lightweight outsourcing soft steel plate 6, and a cable 7 , fixing bolt 8, connecting beam 9, concrete base plate 10, lightweight energy-dissipating material 11, reinforcing foundation 12, reinforcing base 13, ground 14, vertical connection fixing pile 15, anti-collision barrier monomer 16, end energy dissipation Steel plate 17, side energy-dissipating steel plate 18, energy-dissipating extrusion tube 19, built-in reinforcing steel bar 20 and concave-shaped connecting stirrup 21; Enclosed by the upper sealing plate 2, the lower sealing plate 3, the end plate 4, the anti-collision protection pad 5 and the concrete base plate 10, a light-weight outsourcing soft steel plate is arranged at the position adjacent to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com