Fabricated anti-flood wall

A flood wall and prefabricated technology, applied in dikes, breakwaters, coastline protection, etc., can solve the problems of large manpower and material resources, complicated on-site assembly, easy to be washed away, etc., to achieve simple construction and installation, good structural stability, and improved The effect of structural stability and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

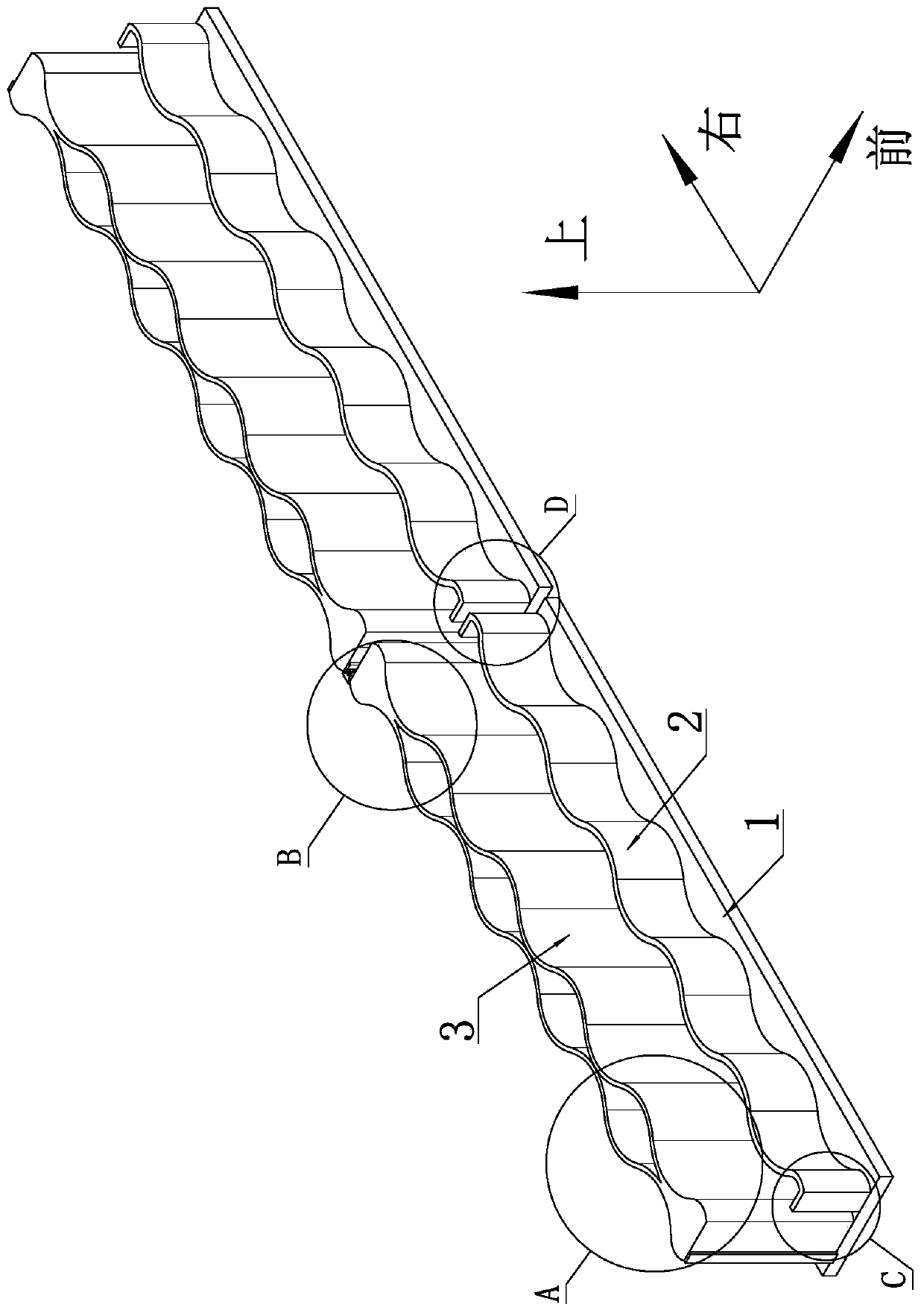

[0034] For the convenience of description, the coordinate system is defined as figure 1 shown.

[0035] Such as figure 1 As shown, a prefabricated flood wall includes several flood wall monomers, and several flood wall monomers are sequentially connected by connecting structures to form a continuous wall.

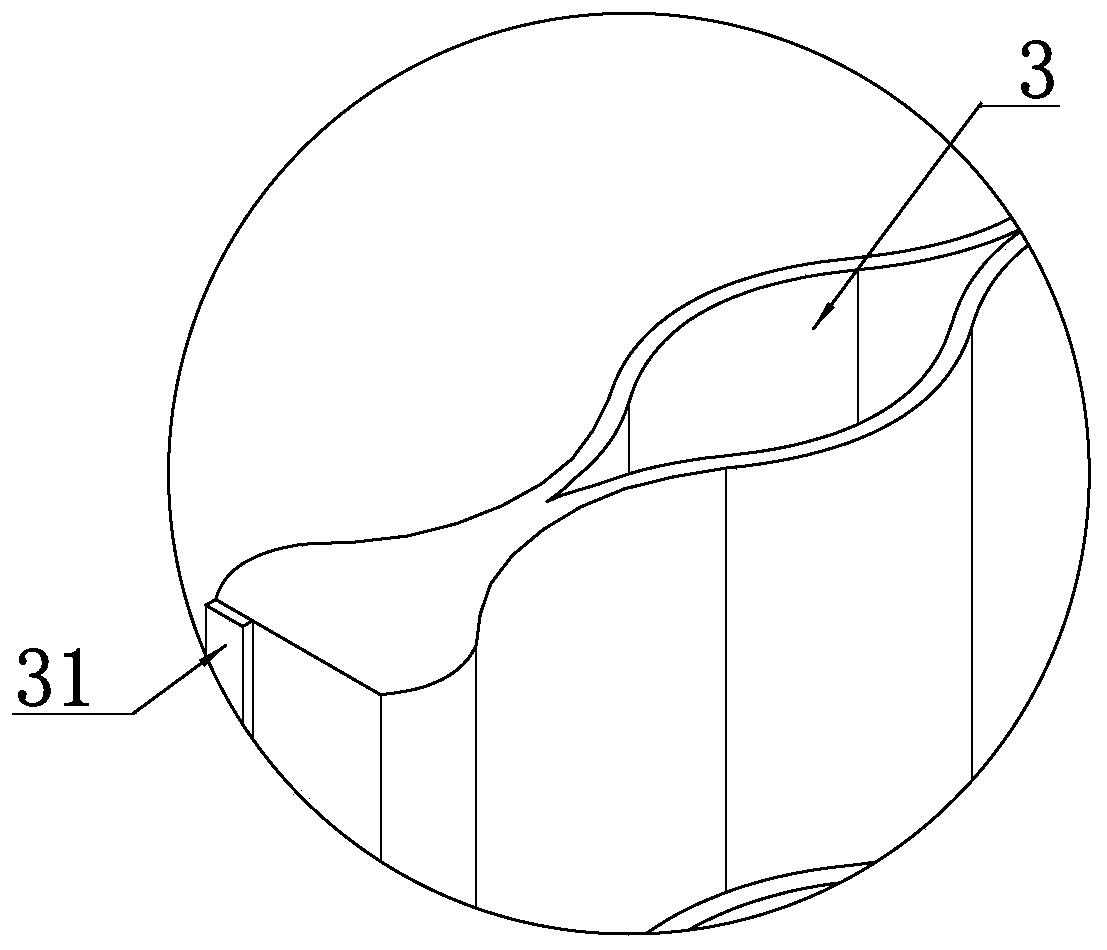

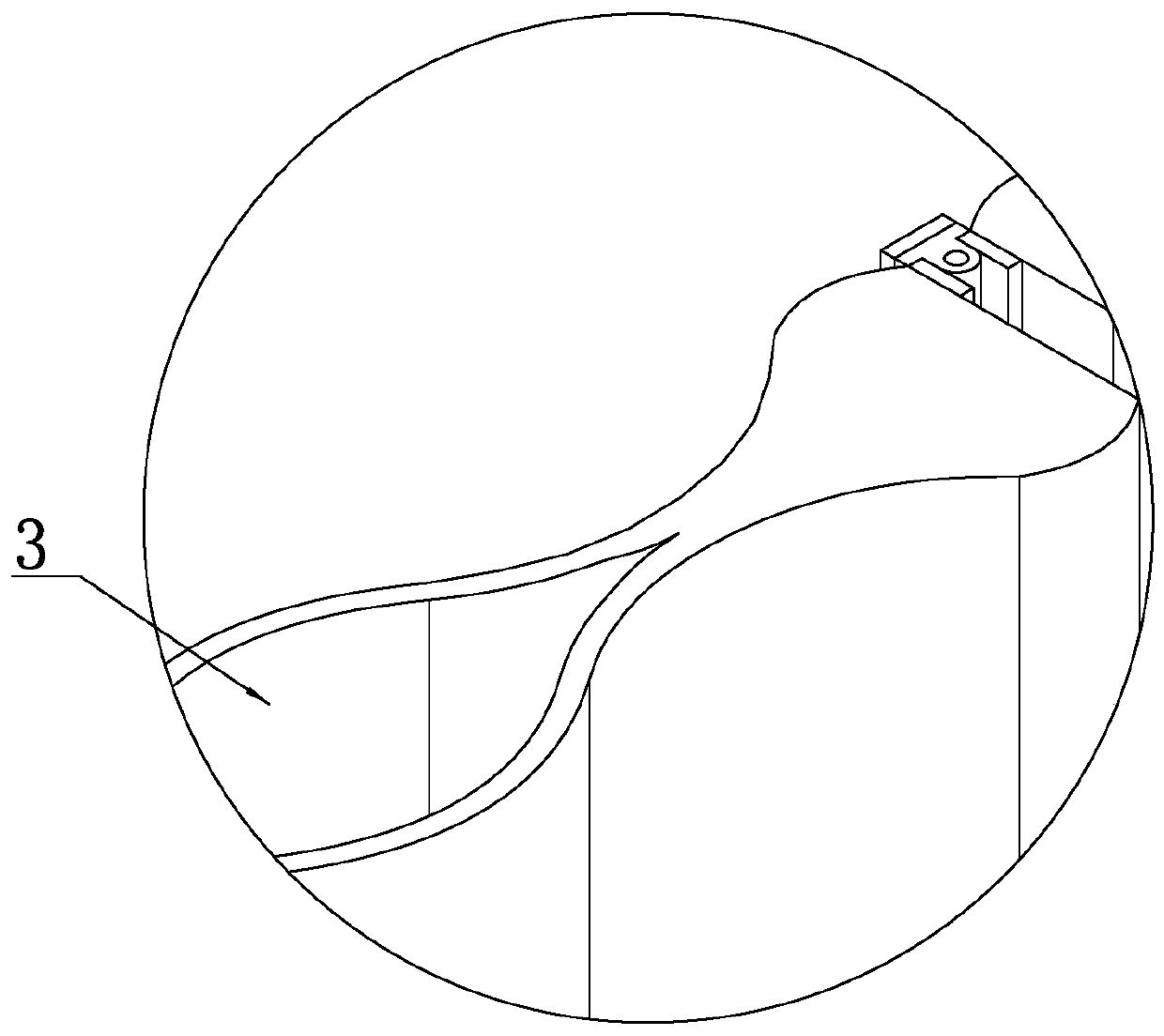

[0036] Such as figure 1 As shown, the flood control wall monomer includes a base plate 1, and a water retaining wall 2 with a wavy curved surface is arranged on the base plate 1, and a wave wall 3 is arranged on the rear side of the water retaining wall 2, A water storage area is formed between the wave break wall 3 and the water retaining wall 2 .

[0037] As a specific implementation, in this embodiment, the height of the retaining wall 2 is 1 meter, the height of the anti-wave wall 3 is 2 meters, and the width of the water storage area is 0.6 meters.

[0038] Such as Figure 6 and Figure 7 As shown, the left and right ends of the wave-proof wall 3 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com